Borrowing ideas that nature incorporated into biological eyes promises a new generation of optical systems.

Engineers have spent centuries perfecting glass optics since the first spectacles came into use in the 13th century. But nature has spent hundreds of millions of years evolving living eyes, and when Len Buckley arrived at the Defense Advanced Research Projects Agency (DARPA; Washington, D.C.) in early 2002, he thought we might learn something from them. The “bio-inspired” optics program-officially BOSS for Bio-Optic Synthetic Systems-he created is borrowing some of these ideas to build better optical systems.

Biological eyes offer some impressive capabilities, Buckley points out. Up until middle age, the lens of the human eye is a natural zoom lens with wide focal range, based on its ability to change both its shape and refractive index. The human lens has an impressive internal nanostructure of 22,000 thin layers that grade its refractive index. The human eye also offers foveal vision-that is the ability to see a small field at much higher resolution than the rest of the field of view. This arises from the high density of light-detecting cones in the fovea at the center of vision in the retina.

The eyes of living things are made of fragile materials, and their optical performance is limited by biological constraints. But they pack a lot of performance into a package much smaller than conventional glass zoom lenses, which focus by moving several glass elements back and forth. The DARPA program is developing new materials to replicate key functions of the human eye in ways that can be plugged into modern optical systems. After initially funding more than a dozen research projects, Buckley has selected four projects that look most promising for near-term demonstrations in potentially interesting systems.

Dynamic materials

Glass is a wonderful optical material, but it is static, fixed in a particular shape, and unchanging in focal power. To make a zoom lens with glass, fixed elements must be moved back and forth. Good glass zoom lenses are big, heavy, and expensive-and suffer from a limited field of view. Buckley’s program is turning to new materials that offer ways around these limitations.

One approach is materials with internal microstructures that can be altered to change their shape and/or refractive index. Microfluidics can produce those changes by varying internal pressure. The familiar technology of liquid crystals offers a way to modulate refractive index. Laminated stacks of plastic nanolayers can also be manipulated to change their refractive index.

Microstructures also can be used in a different way, to create diffractive optics with wide fields of view and strong focal power.

Variable lenses

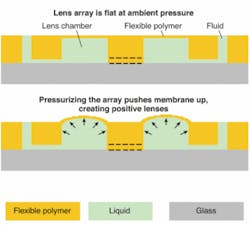

The Rockwell Science Center (Thousand Oaks, California), MIT (Cambridge, MA), the University of California-San Diego (San Diego, CA) and AeroVironment (Monrovia, CA) are working on a deformable microfluidic lens. Pumping high-index fluids into and out of a membrane lens changes its shape and can also change its refractive index, making the lens zoom (see Fig. 1). The human lens can change its refractive index by 0.03, but the DARPA project is targeting a ∆n change of 0.2, a factor of seven higher.

The goal is a 30-power visible-wavelength zoom lens to be demonstrated in a Pointer unmanned aerial vehicle (UAV) made by AeroVironment early this year. Buckley says the system should have a field of view ranging from 8° to 68°, compared to 1° to 30° in a state-of-the-art conventional glass zoom lens. The microfluidic lens should weigh in at about 100 g, compared to 2 kg for the glass zoom lens. That’s a potentially big advantage in a UAV, in which weight is a critical issue.

Eric Baer’s group at Case Western Reserve University (Cleveland, OH) and researchers at the Naval Research Laboratory (NRL; Washington, D.C.) are developing a solid-state dynamic lens. Their system is a gradient-index (GRIN) lens, made of alternating layers of two plastics tens of nanometers thick. Like the lens of an octopus eye, the lens is spherical, with the GRIN structure compensating for spherical aberration. The spherical shape enhances the field of view.

Conventional GRIN lenses are not dynamic, but the program is working on dynamic versions, and targeting a refractive-index change larger than 0.2. Such large index differences allow the lens to have the refractive properties of a spherical lens, but be relatively thin and small. Chromatic aberration is not a major concern because the optical system will work over only a limited range of wavelengths. This system will be even more compact than the microfluidic lens, perhaps weighing in at a couple of grams. The Naval Research Laboratory is testing it on its Dragoneye UAV, which is smaller than the Pointer.

Foveal vision

Animals evolved the fovea so they could survey a wide field of view, but focus quickly onto a small area when necessary. Eagles have evolved a pair of fovea so they can focus fine vision on two spots in the eye. Exactly how their eyes work is not clear, but this appears to be how their “eagle eyes” can spot prey from the air. Modern humans use their foveas for reading and close work, but our distant ancestors used them to keep an eye on their surroundings, to look out for saber-tooth tigers, or spot a meal. Our eyes instinctively turn toward a direction in which we sense motion, so we can see what’s moving.

A similar capability could be invaluable for combining wide field of view and high resolution in imaging and surveillance systems. Modern systems have to trade off field of view against resolution for continuous monitoring, or to repeatedly scan the whole field of view, seeing only a limited area at high resolution at any one time. A foveated vision system would simultaneously monitor a small field of view at high resolution and a broader field at lower resolution, reducing the total number of pixels that have to be processed, thus increasing speed and lowering costs (see Fig. 2). The high-resolution zone would move across the whole field of view as necessary.

To test the concept, a team led by the University of Central Florida (Orlando, FL) is building a spatial-light modulator based on transparent liquid crystals. Most spatial-light modulators are based on reflective liquid crystals, but DARPA wants a truly transmissive device that can be placed in front of a sensor or camera system. Modulating its refractive index makes the liquid crystal act as a gradient-index lens. Varying the applied electric field changes the alignment of the liquid crystals, and because liquid-crystal molecules are strongly birefringent, this produces a large change in the refractive index-and thus the focal length of the liquid-crystal lens.

In operation, applying voltages across selected parts of the liquid crystal would create a foveal region, and light passing through this region would be imaged with higher resolution on the sensor. That system, which is being developed in collaboration with Sandia National Laboratory (Albuquerque, NM), the Air Force Research Laboratory (Albuquerque, NM), Boulder Nonlinear Systems (Lafayette, CO), and others, will be tested on a helicopter, probably this summer.

Photon sieves

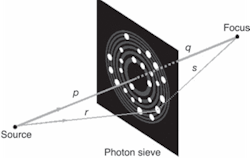

A fourth program was inspired by the eye of the brittle starfish, which images through an array of diffractive microlenses. DARPA’s twist on this idea is to use an array of tiny holes called a “photon sieve,” which are distributed across an opaque surface like the transparent zones in a Fresnel zone plate. With proper distribution of the holes, they can replicate the focusing effect of a Fresnel zone plate, but with finer resolution and better suppression of higher diffraction orders (see Fig. 3). The idea has attracted considerable attention for x-ray imaging, but many demonstrations have been at optical wavelengths.

Diffractive optics are wavelength-sensitive, but Paul Holloway’s group at the University of Florida (Gainesville, FL) is working on optical photon sieves capable of multiwavelength operation. They create arrays of subwavelength holes in metal films, where the surface-plasmon effect greatly enhances light transmission through the holes.

Like other diffractive lenses, the photon-sieve array is much smaller and lighter than a conventional lens. It also promises optical capabilities not possible with bulk optics. “You can design it with a very wide field of view, up to 180°, on a flat chip with very good depth of field,” Buckley says. It can scan a wide field of view without moving parts. The goal is to replace a gimballed lens system in a munition, reducing weight by about 65%. DARPA plans to complete a demonstration this summer.

Outlook

Part of DARPA’s job is to establish the capabilities of each system and operating requirements for their applications. For foveated imaging, Buckley would like a response time in the one-second range. The fluidic zoom lens could shift its focus in about 10 seconds. However, speed is not necessarily a limiting constraint. The goal is to make available new functions not possible with fixed-index optics.

The current round of programs is aimed at breadboard demonstrations and capability demonstrations. Operational systems are some way off. Other materials that DARPA tested in its phase-one projects may get a second look as they mature, such as moving transparent liquids inside photonic crystals to change refractive index. It may take a while to find an ideal combination, remember that living eyes have been evolving for more than a half-billion years.

REFERENCE

1. N. Chronis et al, Optics Express 11, 2370 (Sept. 22, 2003)

2. L. Kipp and L. Kipp et al, Nature 414, 184, (Nov. 8, 2001).