IMAGING IN HARSH ENVIRONMENTS: Harsh environments dictate design of imaging spectrometer

Manufacturers of imaging spectrometers typically build instruments to the highest specification, knowing they will be used in stable and predictable environments. But what if the sample to be measured cannot be physically transported to the laboratory?

DAVID BANNON AND ROBERT THOMAS

When designing a spectral engine for use in remote field applications, one of the most important objectives is that it must be rugged and extremely reliable, with few moving parts-to minimize downtime. In many applications, the equipment is being used in a hostile environment that is not conducive to routine maintenance or ongoing calibration and alignment. Ideally, the instrumentation should be small and compact, so it can be placed in confined areas or easily carried to remote sampling locations. In addition, to maintain high optical performance with minimal weight, product designs should be based on reflective optics, which offer optical efficiency and high signal-to-noise characteristics. Optomechanical engineers typically shy away from transmissive, prism-based products, which inherently generate excess stray light and cause significant problems associated with thermal instabilities.

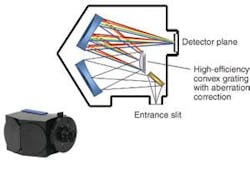

FIGURE 1. A hyperspectral-imaging spectrometer that uses an aberration-corrected, high-efficiency convex grating in a concentric Offner configuration, creates a high-performance, compact design that can be used in a variety of harsh imaging applications.

It should also be emphasized, however, that even though a rugged design is important, optical flexibility is a critical component of a field-based instrument. It is extremely important that the spectrograph can be customized for application-specific requirements, particularly for program managers who are addressing multiple discrete threats or requirements. For example, the spectral range and resolution of a Raman spectrometer used to identify mineral deposits will be very different from a hyperspectral imaging spectrograph carrying out remote sensing of a few hundred square kilometers of an ocean to look for signs of submarine activity. This is particularly true in low-light environments when the requirement is to detect weak signals in the presence of very high background noise. And finally, for many applications in which large amounts of spectral information must be processed simultaneously, it is also desirable to be able to place multiple spectral regions onto a single detector plane without compromising the overall size of the system.

The Offner spectrograph

When all these requirements are taken into consideration, it is clear that traditional optical configurations like the Czerny-Turner planar design have serious limitations, mainly because of the need to correct for smile (change of dispersion angle with field position) and keystone (change of magnification with spectral channel) image distortions. Based on the experience of our design team, the preferred optical-design configurations for imaging instruments are based on modifications of a concentric Offner configuration. This design, a variation of the unit-magnification concentric optical system described by Offner in 1956, utilizes a pair of concentric spheres and an original, aberration-corrected, convex holographic grating with very low stray-light characteristics. This configuration offers the advantage of high-quality imaging quality-free of higher-order aberrations, very low distortion, and low f number- making it ideal for spectral imaging in low-light, low-signal applications.

The field of view and imaging quality of this spectrometer is defined by its f number (acceptance angle) and the width and height of the entrance slit, which is matched with the detector array and pixel size. The symmetry of the optical design provides low distortion, allowing for superior spectral and spatial resolution. To compensate for higher-order astigmatism asymmetry introduced by the grating dispersion, the system is optimized using the radii, spacings, and tilts as variables with aberration-corrected, holographic convex gratings.

Because the unit is constructed entirely from reflective optics, it can accommodate any wavelength band from the low ultraviolet (UV) to the long-wave infrared (IR) without suffering performance degradation typically associated with the high scatter and thermal instability issues of prism-based systems. If made with original holographic diffraction gratings, reflective optics also benefit from significantly less stray light, which allows the instrument to detect weak signals in an environment with higher background noise. The original holographic diffraction grating can also be fine-tuned during manufacturing to provide the necessary chromatic dispersion and peak efficiency to match most camera formats currently available. And finally, unlike filter or scanning Fourier-transform-infrared (FTIR) systems, a grating-based imaging spectrometer with a modified Offner design obtains the spectra of each point simultaneously in a line using a push-broom scanning technique, thus avoiding the mixing of spectral signatures in a temporally changing measurement, while maintaining precise spectral and spatial resolution (see Fig. 1).

Commercial imaging applications

Since their development more than 20 years ago, remote-sensing imaging technology has gradually expanded from its initial use as a government research tool into more commercial application areas, including industrial process monitoring, precision agriculture, environmental assessment, and medical diagnostics. This transition has been slow because most of the research has focused on addressing the demands of federally designated tasks, and, as a result, there has been limited investigation into the commercial marketplace. However, recent breakthroughs in the design and performance of optical components are enabling the development of instruments operating in the low UV up to the long-wave IR region-including the use of new Raman laser excitation sources-allowing manufacturers to develop fully integrated spectrometers that focus on more commercial uses. These application areas depend on design innovations that enable high optical performance in small, rugged, lightweight form factors.

Airborne and space surveillance applications use hyperspectral sensors that incorporate stationary two-dimensional (2-D) array detectors in which the motion of the platform-airplane, unmanned aerial vehicle (UAV), or satellite-effectively scans the spectrograph slit over the area to be imaged, reducing instrument complexity by eliminating the need for moving parts. A frame grabber then builds a 2-D visual image at each spectral channel, which, when plotted against wavelength, yields a three-dimensional (3-D) hyperspectral data cube of the area being surveyed.

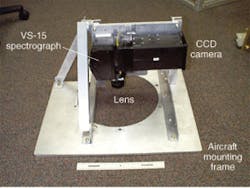

A good example of this sensing technology is the Portable Hyperspectral Imager for Low Light Spectroscopy (PHILLS) designed by Headwall Photonics for the Naval Research Laboratory (NRL; Washington, D.C.; see Fig. 2). This sensor was designed to assess environmental makeup of coastal regions. In this project, a customized hyperspectral-imaging sensor was mounted in an airplane, which then flew at 10,000 ft above sea level at a speed of 100 mph to spectrally map the test region. The imager was initially tested on an island in the Bahamas. By using the 3‑D hyperspectral-data approach, the sensor was able to differentiate between sand, grass beds, and coral reefs in this complex coastal environment.

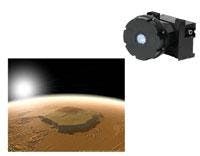

FIGURE 3. A multispectral Raman spectrometer is being used in NASA's Mars Instrument Development Program (MIDP) to determine the mineral, water, and organic components on the surface of Mars.

Characterizing the landscape of Mars is another exciting area of imaging research being conducted by the National Aeronautics and Space Administration (NASA; Washington, DC), under the Mars Instrument Development Program (MIDP). In this project, the NASA team is working with a team of spectroscopy experts including Bruce McIntosh of Hamilton Sundstrand (Rockford, IL), Bonner Denton from the University of Arizona (Tucson, AZ), and engineers from Headwall Photonics to develop an innovative Raman spectrometer to identify the different mineral, water, and organic components on the surface of Mars (see Fig. 3). The benefits of Raman scattering are well documented, but this is the first time it will be used in such a challenging environment. One of the major advantages of this instrument is its light-gathering performance, which means it can detect very weak signals in high-noise background environments. In addition, because of its multi-input design, multiple spectra can be placed on a single detector plane. Therefore, by incorporating fiberoptics into the design, multiple Raman probes or calibration sources can be utilized. To date, the system is demonstrating some extremely promising data and has surpassed commercial Raman systems in terms of exhibiting superior band shape and spectral resolution. If the remainder of the testing phase is as encouraging, the plan is to launch the instrument on a mission to Mars in 2009.

Detection of biological and chemical agents with spectral sensing is a major initiative of the Departments of Defense (DOD; Washington, D.C.) and Homeland Security (Washington, D.C.). In these situations, the target area suspected of contamination is radiated from a distance with a remote field device or excitation source. The signal is then reflected back toward the imager, where the spectral information of the target substance is compared to a library of harmful or toxic agents. Such techniques, which include UV Raman analysis or hyperspectral sensing, allow an assessment of the threat to be made remotely without ever going near the potentially dangerous area. These techniques can also be used to detect the composition and spread of hazardous environmental spills to determine whether the substance threatens water supplies or wildlife habitats. The potential exists to couple this technology with wireless capability to create broad sensor networks for “fence-line” monitoring of geographic areas and infrastructures.

The final analysis

The major breakthrough in the commercial acceptance of field-based spectral-imaging techniques is that superior optical performance can now be achieved in a compact, reliable instrument design. In addition to the application areas described, hyperspectral imaging also holds promise in significantly enhancing health care through noninvasive early cancer detection and scanning DNA microarrays to measure gene activity. There is no doubt that innovations in spectral sensing and remote analysis will continue to drive the adoption of smaller, more portable instruments for emerging applications across a broad range of markets.

David Bannon is vice president of sales and marketing at Headwall Photonics, 601 River St., Fitchburg, MA 01420; and Robert Thomas is principal of Scientific Solutions, 4615 Sundown Rd., Gaithersburg, MD 20882; email: [email protected].