So-called “pseudo-nondiffracting” light beams, which have a beam profile shaped such that it remains virtually unchanged over long distances, can be useful in optical-tweezer systems. The profiles of these beams usually approximate a mathematical shape called a Bessel function. (The beams do indeed diffract, but the diffraction is such that the profile changes relatively little over a well-defined distance before spreading rapidly.)

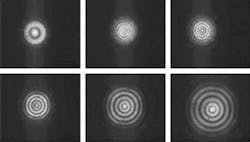

Creating such a beam is not easy, but is possible using Fabry-Perot etalons, annular slits, or conical lenses (axicons). The results, however, are often not optimal, resulting in a beam that spreads too early and quickly. For axicons, the quality of the beam is directly related to the quality of the conical lens itself. Researchers at Nanyang Technological University (Singapore) and Shenzhen University (Shenzhen, China) are creating small, high-quality axicons of SU-8 photoresist on glass using electron-beam lithography.1 The axicons produce a Bessel beam with an 80-µm-diameter central spot that stays approximately the same size over a 20-cm distance (see figure).

The very shallow axicons, which have a wedge angle of about 0.5°, would be difficult to fabricate using other techniques, but electron-beam lithography enabled reproducible single-step fabrication. The SU-8 resist film used had a relatively low exposure contrast of 0.7, which eased fabrication by reducing structure-height errors resulting from electron-beam dosage variations. A typical axicon was 4.36 µm high and 1 mm in diameter.

With 300 mW of laser power striking the axicon, the Bessel beam was used to trap and levitate a 5-µm silica sphere. Adding a quarter-wave plate to give the beam a bit of spin angular momentum allowed the beam to trap and rotate a calcite particle about 8 µm in size.

Many ways to levitate

The research group has developed other approaches to optical trapping and levitation, including spiral phase plates that produce focal spots with a null at their center (see Laser Focus World, February 2005, p. 9). In fact, several approaches exist, says Xiaocong Yuan, one of the researchers. A spot without a central intensity null can trap only high-refractive-index objects, but is easy to produce because it is merely a focused Gaussian beam. A beam with a central intensity null traps high- and low-index objects, but requires complex optics such as a spiral phase plate, which produces a Laguerre-Gaussian beam, or optics that produce a higher-order Bessel beam.

Gaussian or Laguerre-Gaussian beams, like most beams, are not propagation-invariant; therefore, they trap a particle in all three dimensions, completely confining a particle. Bessel beams trap in only two dimensions, which for some applications—such as trapping on a microscope slide or other plane—is an advantage, because there is no focal point that can drift to an out-of-plane position. In addition, the self-healing (as well as propagation-invariant) properties of a Bessel beam allow it to trap long strings of particles, says Yuan.

Micro-axicons could be useful for lab-on-a-chip technologies. For example, an axicon integrated with a diode laser could produce an optical-tweezing Bessel beam suitable for a chip constructed of components with sizes all in the micrometer range.

REFERENCE

1. W. C. Cheong et al., Applied Phys. Lett. 87, 024104 (July 11, 2005).

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.