OPTOELECTRONIC APPLICATIONS: SURVEILLANCE - Optical sensors improve consumer safety

The need to develop more-advanced technologies for military reconnaissance, homeland security, and environmental monitoring has helped optical sensors become critical components of modern-day surveillance systems. Security cameras have been widely used in homes and businesses for decades, from the early black-and-white analog versions to today’s digital color image sensors. But optical technologies are also enabling increasingly sophisticated surveillance applications, from camera systems that can identify individuals by unique facial features or mannerisms to biosensors that can pinpoint potentially harmful air- and water-borne pathogens.1

These same technologies are also being adapted into consumer products such as camera phones, interactive toys, automobiles, and home appliances. In addition, more-advanced combinations of image sensors, optical detectors, and data-processing algorithms are fueling a host of “smart” surveillance systems designed to improve consumer safety, giving the term “surveillance” a whole new meaning. PerkinElmer Optoelectronics (Fremont, CA) claims to sell more than 150 million CCD and CMOS sensors annually for consumer applications ranging from security (surveillance systems, intrusion alarms, and smoke detectors) to automobiles (climate control, adaptive cruise control, antifogging, twilight sensing, and gas monitoring), and appliances (thermostats, air conditioners, microwave ovens, and ear thermometers). Similarly, Omnivision (Sunnyvale, CA) ships between 120 million and 140 million CMOS sensors each year for security applications and is now turning its attention to automobiles and high-end surveillance applications previously dominated by CCD detectors.

“When it comes to surveillance—from general security to medical imaging—the bottom line is you are looking for something,” said Hasan Gadjali, director of marketing for advanced products at Omnivision. “In the sensor area, the need now is for more intelligent systems. Not just a camera that takes a picture, but one that knows whether the trigger of the alarm is valid or false. And the technology is moving in this direction to address issues such as lighting, direction, and the need to keep trying to reduce the price.”

On the road

Aside from surveillance cameras, automobiles and traffic management represent one of the largest consumer-safety markets for optical sensors. Cameras have long been used on roadways to monitor traffic situations and identify lawbreakers, but researchers in the United States and Europe are also using imaging systems to record patterns in traffic speed and density in an effort to improve traffic management.2 In addition, with an eye toward enhancing driver safety from the inside out, car manufacturers are adopting optical sensing systems for applications ranging from air bag controllers to rear vision, night vision, and driver alertness.3

“There is a definite need to put cameras in cars for safety reasons,” said Mike DeLuca, manager of product marketing for Kodak Image Sensor Solutions (ISS; Rochester, NY). “Car manufacturers and governments in Japan, the United States, and Europe see this need and are pushing for these driver assistance systems.”

Leveraging CMOS technology developed internally and acquired through its purchase of National Semiconductor’s imaging business, Kodak ISS is targeting “everything that has to do with automotive imaging applications, including interior and exterior viewing, adaptive cruise control, and occupant detection,” according to Gun Poespowidjojo, segment manager. The company is working with Toyota on a lane-departure warning program and with Volvo on a sideview blind-spot detection system (see “Vision systems improve road safety”). The latter uses CMOS imaging-array cameras mounted in a chrome viewing port below each side-view mirror (see Fig. 1). Each camera images at a rate of 25 frames/s with an array resolution of 640 × 480 pixels. A digital signal processor determines the location and relative speed of any vehicle within the blind-spot area. The system controller lights a triangular LED lamp to signal the driver when a vehicle is in a 30 × 10‑ft blind spot area to the rear and side (in other applications, the driver is alerted via sound or vibration).

Not surprisingly, the demands on the sensors in such systems are high. They must function in severe heat, freezing cold, darkness, and direct sunlight, often in rapidly changing conditions, and they must be able to capture, read, and transmit reliable information instantaneously. In response to customer requests for higher resolution, better light responsiveness and dynamic range, and faster frame rates, Kodak is working to increase the robustness and reliability of its CMOS sensors—by using shared architecture to reduce the amount of circuitry around each pixel and thereby increase photosensitivity, and using nonlinear pixel response to improve dynamic range. By changing the response of the photodetector so that it is no longer linear, said Poespowidjojo, the sensor can show the dark and bright regions of an image simultaneously.

“Our first generation (of sensors) is adequate for what our customers are doing right now in their first-generation applications, but as the applications gain more intelligence, such as adding graphics or touch-screen capabilities, our customers will be asking more and more from our systems,” he said.

Closer to home

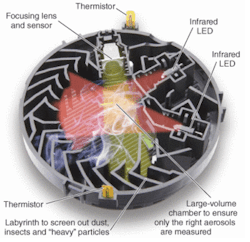

In addition to image sensors, other kinds of optical detection systems are also finding their way into the consumer realm. Researchers at Siemens Building Technologies (Zug, Switzerland) have developed a smoke detector that combines optical and thermal sensors. According to Siemens, unlike conventional smoke alarms that go off when smoke in the air exceeds a certain concentration but are unable to distinguish between different types of smoke, the Sinteso detector can differentiate between a real fire and the causes of common false alarms such as cooking fumes, insects, steam, and dust. It can also determine the severity of the fire.

The heart of the system is an optoelectronic sampling chamber comprising two thermal sensors that monitor heat and temperature changes and two LED-based IR sensors that monitor the size and color of the smoke (see Fig. 2). As soon as smoke enters the chamber, the sensors begin to operate; one IR sensor is positioned to collect the forward scatter, the other to collect the backscatter. The signals from the four sensors are then combined and analyzed using proprietary neural networking algorithms that enable “exact assessment” of disturbance variables. In addition, the system’s integrated circuits are programmed with typical parameters—such as temperature patterns, smoke color, and particle size—specific to the room in which the detector will be placed.“There are two sensors because smoke is made up of aerosols that each have a unique diameter; the general rule is the darker the smoke, the bigger the diameter, so very dark smoke tends to absorb in the IR rather than scatter,” said Andrew Morgan, integration manager at Siemens Building Services U.K. “We can alter the angle of one of the optical sensors so that it looks for the backscatter from these molecules. The other sensor is looking for forward scatter, which is important for lighter smoke (such as wood smoke) that scatters all over the place. This has been the challenge in smoke detectors for a long time, but by changing the angle and increasing the gain, we can overcome it.”

Looking ahead, optical sensors may one day also make our food safer. A government-sponsored project in Ireland called Intellipak (November 2001 to September 2004), focused on developing printable fluorescent sensor coatings for oxygen and carbon dioxide in food packaging, plus a scanning instrument to read those coatings.4 BioCop, another European Community project, was established to help small companies and academia pursue novel approaches for the detection of multiple chemical contaminants in food.5 For example, as part of this program, Chalex Research (Belfast, Ireland) is developing a biosensor that uses surface plasmon resonance to detect toxins in shellfish.

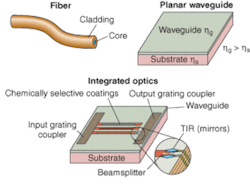

In the United States, researchers at Georgia Tech Research Institute (GTRI; Atlanta, GA) are taking a slightly different approach to optical sensing, and the result could have broad implications in food safety and other consumer applications. Under the direction of Dan Campbell, senior research scientist, the researchers have developed a low-cost sensor platform consisting of a laser light source, planar waveguide, and detector for monitoring light output (see Fig. 3). Reactions on the waveguide surface alter the speed of light through the waveguide. This change is monitored with an interferometer by comparing a reference beam with another beam traveling under the sensing chemistry. Signal processing software interprets the sensor’s results and delivers information on the agents’ identity and quantity. The waveguide chip is small enough that it can accommodate several sensing channels designed to detect a wide variety of chemical and biological agents. To sense biological agents, the device takes rapid, direct measurements of the binding of an antigen to a chemical receptor on the waveguide surface. The key to this technology is its simplicity and low cost, according to Campbell.“We’ve built one platform for many possible uses, both in the air and in the water,” he said. “The platform is a piece of glass with a compound on top of it that guides the light. We use silicon nitride for the waveguide and use chemical deposition to put down the waveguide in an evanescent field that extends out about 5000 Å. And because interferometry is wavelength independent, we can use the cheapest light source and the cheapest detector we can find—a diode laser at 670 nm (although we could use other wavelengths), and for the detector the guts of a web cam, which costs about $35. So the whole thing is very cheap but has a wide variety of uses; depending on what we are trying to detect, all we have to do is change the chemistry.”

Campbell and his colleagues have successfully detected numerous agents, including salmonella and campylobacter bacteria, anthrax, ricin, chlorine, and ammonia in laboratory tests, and groundwater contaminants such as chlorinated hydrocarbons in field tests. Commercialization efforts are now under way; potential applications include detection of industrial pollutants, methamphetamines and other drugs, chemical and nerve agents, and food-borne pathogens.

REFERENCES

1. C. Yang, BusinessWeek (Aug. 8, 2005).

2. B. Meffert et al., “Monitoring Traffic by Optical Sensors,” 2nd Int’l. Conf. on Intelligent Computing and Information Systems (ICICIS), March 5-7, 2005, Cairo, Egypt.

3. A. Wilson, Vision Systems Design 10(5) 35 (May 2005).

4. www.osl.dcu.ie/projects/Intellipak

5. www.biocop.org

About the Author

Kathy Kincade

Contributing Editor

Kathy Kincade is the founding editor of BioOptics World and a veteran reporter on optical technologies for biomedicine. She also served as the editor-in-chief of DrBicuspid.com, a web portal for dental professionals.