OPTOELECTRONIC APPLICATIONS: NANOPHOTONICS - An ‘old’ technique finds new life in the nano world

Long before nano was “nano,” scientists were fascinated with the idea of being able to observe, quantify, and replicate sub-100-nm phenomena they knew were occurring, even if they couldn’t see them. From electron microscopy to Raman spectroscopy, and the many variations of these techniques that have been developed to enhance their sensitivity and resolution, the push to delve further into the nano realm continues to drive development of even more-precise imaging and detection tools, eventually down to the single nanometer scale.

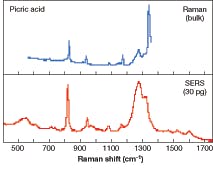

One of the most promising techniques for nanoscale imaging is surface-enhanced Raman scattering (SERS), which increases the Raman signal by up to a millionfold, overcoming the sensitivity limitations of standard Raman spectroscopy (see Fig. 1). The SERS “phenomenon” is by no means new—it was first observed in 1974 by Martin Fleischman and colleagues at Southampton University (Southampton, England) and again in 1977 by Richard Van Duyne at Northwestern University (Chicago, IL).1, 2 But only recently has it begun to transition from academia to the commercial marketplace—in part because of advances in understanding how SERS works and improvements in the technologies used to support it.

“Initially SERS was used primarily in scientific applications where researchers saw it occasionally and knew it was an effect but couldn’t really apply it to an application,” said David Reece, sales manager at Mesophotonics (Southampton, England), a spinout of Southampton University that is commercializing photonic-crystal SERS substrates. “In recent years, however, the scientific community has been able to begin to understand the SERS effect, and the phenomenon is moving into an application phase.”

Surface-enhanced Raman scattering is not inherently an imaging tool but rather a sampling process that increases the sensitivity of Raman spectroscopy by taking advantage of a molecular phenomenon that occurs when a metallic surface is charged with photons (see Fig. 2). When a molecule is in close proximity to a roughened silver electrode and then stimulated with laser energy, the Raman signal increases by as much as six orders of magnitude (106). The enhanced Raman scattering is a result of an analyte adsorbing to a colloid or roughened metal surface (typically silver, copper, or gold) with surface plasmons that are in resonance with the laser—typically a low-power 785 nm diode, although SERS has been shown to be effective in the 532 to 1064 nm range. Because the SERS spectrum is a direct measure of the analyte’s molecular structure, unique spectral signatures are collected, minimizing false positives. In addition, the technique can offer a more detailed spectral picture of the material being detected than is possible with most optical techniques, such as fluorescence. These features make SERS attractive for a number of real-world applications, including homeland security, chemical analysis, forensic science, and medical diagnostics.In homeland security, for example, SERS’ sensitivity, even with low sample concentrations, plus its multienvironmental, multianalyte capabilities, is being field-tested for the detection of trace levels of explosives, chemical-warfare agents, and bacteria in water and vapor. In addition, SERS shows promise for the monitoring of drinking water for chemical agents and other toxic chemicals, notably cyanide.3 In forensics, SERS has been shown to be effective in the detection of low concentrations of inks, bodily fluids, illicit drugs, explosives, and lipstick. In chemical analysis and medical diagnostics, SERS could provide the basis for extremely sensitive early disease testing with little to no sample preparation, producing results in seconds rather than days or weeks by delivering a unique trace of a specific molecular fingerprint of known disease indicators.

“What is unique about SERS is that there are not many techniques where you can get a full spectral fingerprint of the entire molecular structure of a sample at such low concentrations,” Reece said. “Some techniques, such as mass spectrometry, give you the mass of a molecule, but not its bond structure. With SERS, you can get a full structural ID of what you are looking at.”

Despite its many advantages, however, several factors have limited adoption of SERS outside of the scientific community—most notably, the inability to easily and consistently produce uniform substrates, whether using electrodes, colloids (small particles of gold or silver dispersed in an aqueous solution—often now referred to as nanoparticles), or metal surfaces. Some SERS experts contend that the difficulty in manufacturing uniform colloids and producing consistent substrate surfaces has been a major limiting factor in the commercialization of SERS; others, however, say the primary limitation has been finding applications where SERS’ lack of selectivity is not an issue.

Commercial efforts

A handful of companies have begun introducing SERS technologies and products designed to overcome these issues and make the technique attractive for commercial use. Each is taking a slightly different approach to the development and manufacture of substrates that are reproducible and can be configured to a variety of applications. Mesophotonics, for instance, has leveraged its expertise in photonic crystals to develop a line of SERS substrates called “Klarite.” According to the company, Klarite features a new class of highly engineered surfaces with submicron metal cavities. Instead of depending on random roughening or nanoparticle separation and sharp metallic features, these substrates exploit voids architecture; the delocalized plasmons are distributed on the metal surface, while localized plasmons are trapped in the void features. These plasmons interact strongly, both mutually and with the incident light; by modifying the size, separation, and geometry of texture features, the properties of photonic-crystal SERS substrates can be tuned for maximum signal levels.

Mesophotonics is also using semiconductor lithographic techniques to create the photonic-crystal patterns on the Klarite surface, enabling these patterns to be reproducibly fabricated with high precision over large areas. By providing a uniform patterned surface, Klarite slides provide control of the Raman process, giving consistent SERS signals from anywhere on the active surface.

“We have taken a more semiconductor approach to creating a substrate and manufacturing it on a wafer,” Reece said. “We do patterning on the surface of the semiconductor crystal, which improves the coupling efficiency of the laser into the surface. It also provides more uniformity because we use semiconductor-processing technique so we are controlling the surface rather than randomly etching it.”

InPhotonics (Norwood, MA)—already well known for its expertise in Raman instrumentation—is taking a slightly different approach to SERS. Working in conjunction with its scientific partner, EIC Laboratories (Norwood, MA), InPhotonics is developing substrates tailored to particular types of compounds by engineering the surface chemistry, with specific emphasis at this point on homeland-security applications. The company is now working with defense and military customers to test these substrates using a custom fiberoptic probe for ease of measurement.

“Any market where there is a need for detection of molecular species at low concentrations is a market for SERS,” said Nancy Kawai, marketing manager at InPhotonics. “The instrumentation is really quite mature at this point; what SERS companies are working on right now is getting the substrate right in terms of sensitivity, reproducibility, and ease of use.”

One of the most interesting newcomers to this field is Oxonica (formerly Nanoplex Technologies; Mountain View, CA), which has developed glass-coated SERS-active “nanotags” that the company says offer tremendous sensitivity and high information content, while getting around the “bugaboo” of selectivity. According to company president Michael Natan, the 50 nm nanotags are silica-encapsulated gold nanoparticles, with a defined Raman-active reporter molecule attached. The nanotags deliver the multianalyte detection performance of SERS in a flexible reagent format (see Fig. 3). By containing the substrate and reporter molecule together within the glass bead, Oxonica believes its approach improves both sensitivity and selectivity.“SERS by itself is extremely sensitive but extremely unselective,” Natan said. “With our nanotags we can use the signature of the reporter molecule to identify a particular biomolecule (such as proteins or DNA cells). We like the near-infrared as an excitation wavelength because it reduces the background signal associated with fluorescence, and biomedical samples (such as blood) often have significant issues with fluorescence and absorbance.”

Oxonica is currently targeting clinical and life-science applications, including infectious-disease testing, food testing, and other biomedical testing. The goal is to improve upon current diagnostic tools by providing quantitative multiplexed data in the clinical laboratory and at the point of care.

“Our SERS nanotags comprise a completely new approach to optical detection labels,” said David Browning, head of the health-care business at Oxonica. “We have taken advantage of the key benefits of SERS (near-IR excitation, ultrasensitivity, and high information content) and, through our reporter-loading and glass-encapsulation processes, circumvented the main limitations of the technique (absence of selectivity and lack of robustness). Accordingly, we believe these nanoscale SERS substrates will have a significant impact in life science.”

REFERENCES

1. M. Fleischman, P.J. Hendra, A.J. McQuillan. Chemic. Phys. Lett. 26, 123 (1974)

2. D. Jeanmarie, R. Van Duyne, J. Electroanalitical. Chem., 84, 1 (1977).

3. N. Kawai, and K. Spencer, Spectroscopy (June 2004).

Kathy Kincade | Contributing Editor

Kathy Kincade is the founding editor of BioOptics World and a veteran reporter on optical technologies for biomedicine. She also served as the editor-in-chief of DrBicuspid.com, a web portal for dental professionals.