Interband-cascade laser needs only simple thermoelectric cooling

Interband-cascade (IC) lasers are distinct from quantum-cascade (QC) lasers, which are intraband. Unlike QC lasers, no fast-phonon scattering is involved in IC lasers, resulting in very low threshold-current densities; in addition, the tailorable wavelength range of IC lasers includes the 3 to 4 µm region, important in space exploration for sensing the hydrocarbons that indicate the presence of life. But IC lasers have traditionally required liquid-nitrogen cooling. Researchers at the Jet Propulsion Laboratory (Pasadena, CA) have, however, created an IC laser with a 3.3 µm continuous-wave output at temperatures up to 264 K, allowing simple one-stage thermoelectric cooling.

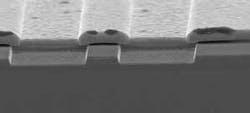

With antimony-based quantum wells and fabricated on a gallium antimonide substrate, the laser has 12 cascade stages and was processed into 10 µm wide double-channel mesa stripes. A 7 µm layer of gold (top layer in photo) was deposited on the top contact, resulting in the high heat dissipation that makes relatively high-temperature operation possible. In pulsed mode, the laser operates at up to 350 K. The emitter is being developed for an upcoming mission to Mars. Contact Rui Yang at [email protected].