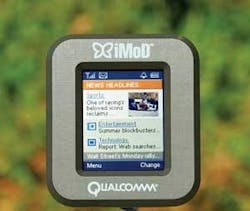

The same process of light interference within thin films that gives color to butterfly wings and peacock feathers is being implemented in a microelectromechanical-systems (MEMS)-based interferometric-modulator display technology developed by Qualcomm (San Diego, CA).1 Called iMoD, this biomimetic display uses thin-film optics and MEMS structures to create an always-on bistable reflective display that consumes far less power and has paper-like readability (even in direct sunlight) compared to organic-light-emitting-diode (OLED) or liquid-crystal displays (LCDs). The iMoD is currently in the development stage (see figure).

The basic structure of an iMoD pixel consists of a glass substrate that is coated with thin films. On the same substrate is a reflective, conductive membrane, which is separated from the glass by an air gap. In this state—the open state—the pixel is bright and has color generated by the interference of light based on the air-gap thickness. By applying a voltage to the membrane and the thin films on the glass, the membrane is electrostatically attracted to the glass. This reduction in the air gap, called the collapsed state, causes the pixel to appear black because the light entering the pixel now experiences destructive interference in the visible spectrum.

To create a full-color display, grids of red, green, and blue subpixels (each manufactured with a particular nominal air-gap spacing that creates its open-state color) produces full color through spatial dithering—a process that divides a given subpixel into many smaller addressable elements that are driven separately to obtain the desired gray levels. Because this MEMS actuation requires very little power to maintain either the open or collapsed state, an iMoD-constructed display can easily maintain an image for always-on operation.

“The iMoD display’s bistable nature enables it to save a considerable amount of power,” says Miles Kirby, senior director of product management for Qualcomm MEMS Technologies. “While LCD and OLED displays are continually refreshing an image on the screen, an iMoD display can show a given image with infrequent updates and refreshing when the content changes. This is a great advantage for applications that need an always-on display.”

The iMoD display is also compatible with LCD flat-panel-display manufacturing processes. Because it is a reflective display and does not require the complex fabrication steps used in thin-film-transistor (TFT) displays, nor the absorptive color filters and polarizing elements that limit LCD light emission (nor the LCD’s power-hungry backlight), iMoD has a reflectivity that is nearly twice that of reflective LCD TFT displays. The only time that the iMoD requires supplemental lighting is in low-light conditions that would make reading a newspaper difficult.

Because the iMoD pixel can change its display state (color to black) in roughly 10 μs—compared to 10 ms for a supertwisted nematic passive-matrix LCD display—the effects of motion blur caused by slow switching are eliminated from the display. iMoD displays currently have switching speeds of 15 frames per second (fps), and future products are targeted to have speeds of 30 fps to make video-rate displays possible. iMoD displays are also impervious to UV exposure, have a broad operating temperature range from -30°C to +70°C, and have a wide viewing angle.

Many of the attributes of iMoD, including sunlight viewability, low power consumption, wide viewing angle, and high reflectivity are shared by electrophoretic displays. However, electrophoretic displays are bichrome-only and would require complex color filter schemes to implement a full-color display, reducing image quality and brightness. The frame rate of electrophoretic displays is also significantly slower, which prevents video and animation effects.

REFERENCE

1. “Competitive Display Technologies” white paper, iMoD Qualcomm MEMS Technologies (May 2006).

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.