In the last few years, a group led by Asif Khan at the University of South Carolina (USC; Columbia, SC) has worked at pushing light-emitting-diode (LED) wavelengths well down into the 200 nm range. Now, a nearby company has commercialized the technology after making its own improvements, including advances in materials and device technology. While not a spinoff of the group at USC, Sensor Electronic Technology (SETI; also in Columbia, SC) does have Khan as one of its principals. The company’s deep-UV III-nitride-based LEDs are the only ones on the market, and range from 365 down to 250 nm in wavelength. The emitters were exhibited at this year’s Pittcon conference (March 12-17; Orlando, FL).

While Khan and his group have driven down wavelengths in aluminum indium gallium nitride (AlInGaN) LEDs by coming up with ways to increase the proportion of indium without quenching emission, engineers at SETI have concentrated on making a durable, practical device. The company developed its own flavor of epitaxial-wafer technology and invented new design rules for deep-UV LEDs that have increased the efficiency of the deep-UV LEDs by approximately 15 to 20 times, according to Yuri Bilenko, SETI’s optoelectronic products manager. New packaging technology incorporates improvements such as highly reflecting components in the spectral range below 365 nm and new designs for improved thermal management, he says.

One intended application is UV water purification, which is currently done using the 254 nm emission line from expensive and power-hungry mercury-arc lamps. Banks of deep-UV LEDs would serve the same purpose; the SETI LED produces greater than 0.6 mW of light at an optical power density of 10 mW/cm2 from about 120 mW of electrical power. Unlike mercury-arc lamps, which must be optically filtered, the entire output of the LED is directly used for sterilization. “The wavelengths that can be provided by UV LEDs in the range of 260 to 268 nm are much more effective than the 254 nm wavelength produced by mercury lamps, because they target the peaks in DNA absorption spectra,” says Bilenko.

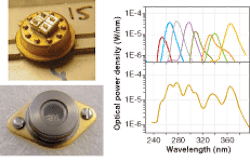

The company has also created (and commercially produces) multichip devices, some of which contain chips of different wavelengths that sum up to produce a broadband UV source, but with independently addressable spectral bands (see figure). Embedded photodetectors provide feedback for each LED. “No similar electronic light source existed before, especially for the deep-UV range, which is extremely important for analytical equipment and systems and biosensors,” says Bilenko. High-power single- or multiwavelength multichip designs can deliver 20 to 30 mW of power, or pulsed power of several hundreds of milliwatts with turn-on times in the nanosecond range.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.