SUPERCONTINUUM SOURCES: Compact femtosecond laser emits white light

Supercontinuum or white-light laser sources—suitable for applications in spectroscopy and microscopy—usually consist of a pump laser and a microstructured fiber (either a photonic-crystal fiber or a tapered fiber). Although 80 fs pulses from a Ti:sapphire laser and 200 fs pulses from an ytterbium (Yb):glass laser have already been used to generate supercontinuum light, researchers at the Universität Stuttgart and the Max-Planck-Institut für Festkörperforschung (both in Stuttgart, Germany) have demonstrated a more-compact and lower-cost portable femtosecond supercontinuum source with a footprint of only 62 × 23 cm2 and a folded-cavity design.1

An isotropic 9.5% Yb-doped phosphate glass with dimensions 5 × 2 × 4 mm3 is used as the gain medium and all parameters are polarization independent, allowing the use of unpolarized fiber-coupled laser-diode pump sources that have a better beam quality than laser-diode bars. Because even moderate pump powers can produce high output, a Peltier cooler can be used instead of water cooling.

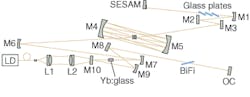

The laser cavity consists of a z-folded design with a total resonator length of 7.5 m, which leads to a pulse repetition rate of 20 MHz (see figure). The laser medium is pumped by a 976 nm, 5.2 W fiber-coupled laser diode from a multimode fiber with a 50 μm core diameter. The laser beam is focused onto a semiconductor saturable-absorber mirror (SESAM) that supports stable solitary modelocking. To minimize the number of components, the intracavity dispersion and self-phase modulation are compensated by flat dispersive mirrors. Finally, an output coupler delivers the output from the resonator, which achieves its long beam path primarily through a Herriott-type multipass cell at the center of the cavity.

Although the cavity structure appears complex, its configuration is mathematically determined by a simple equation. The laser can be tuned by inserting a 1‑mm-thick quartz plate within the cavity that acts as a birefringent filter. Pulses with 180 fs pulse width can be tuned between 1038 and 1047 nm, for example. In the modelocked regime using pump powers between 4.5 and 5.2 W, the laser generated 150 fs pulses at a pulse repetition rate of 20 MHz. Below 4.5 W, continuous-wave (CW) operation of the laser was observed.

Next, this femtosecond laser was used to pump three different kinds of tapered fibers to generate supercontinuum light. To protect the laser against backreflections from the fiber, a Faraday isolator was placed between the laser-output coupler and the fiber-coupler optics. All three fibers had a waist length of 90 mm, but different waist diameters of 2.0, 2.7, and 4.3 μm. The smallest waist diameter produced a supercontinuum spectrum shifted into shorter ultraviolet wavelengths, while the thickest waist diameter shifted the spectrum into longer infrared wavelengths. For the 2.7-μm-waist fiber, a spectrum with an average power of 290 mW was achieved between 400 and 1650 nm when 600 mW of average power was coupled into the fiber by the laser.

The 0.43% root-mean-square (rms) intensity noise of the pump laser resulted in an overall 0.79% rms intensity noise for the white-light source. For a 15 nm spectral section around a center wavelength of 633 nm, computed noise was only 2.34% rms.

The researchers expect that the footprint of this compact laser could be further reduced by using smaller mechanical components. “Compared to a combination of a Ti:sapphire laser with a green pump laser and a nonlinear fiber, this system is at least half the size,” says Felix Hoos one of the researchers. “By using custom components and a smaller pump diode, we believe that it should be possible to nearly halve the size of the laser described in this paper, and it should also be possible to save much space by using smaller fiber-coupling optics.”

REFERENCE

1. F. Hoos et al., Optics Express 14(22) 10913 (Oct. 30, 2006).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.