MOLDED OPTICS: Molded glass aspheric optics hit the target for precision and cost

Until the advent of precision glass molding (PGM) nearly two decades ago, the use of aspheric lenses was a seldom used and expensive optical solution for imaging-optics applications, especially where plastic aspheric lenses lacked the precision or refractive properties required by the lens design. Today, though, consumers routinely use products enabled by glass molded aspheric lenses such as digital cameras, cell-phone cameras, and DVD players. Even with such widespread application, many designers still regard glass aspheres as too expensive to use in all but large-scale imaging optics applications-a notion that stems from a long-held belief that problems associated with aspheric optics, such as reproducibility, accuracy, associated cost, and risk, cannot be affordably overcome.

Better performance and lower cost are no longer mutually exclusive, however. While the tooling costs associated with molding glass aspheres are generally more than that of traditional grind and polish (G&P) lenses, they are typically one-time expenses. Even at modest volumes, tooling cost can be relatively insignificant when amortized over a number of parts-hundreds perhaps-making their cost comparable to that of G&P spherical lenses (and considerably lower than that of G&P aspheres). As such, it may even be economical to mold the spherical glass elements of an imaging system as well. With the economic barrier for using quality glass aspheres effectively removed, lens designers should seriously consider the additional degrees of freedom provided by PGM aspheres (see Fig. 1).

Tooling costs for a small (6 mm diameter) PGM lens-aspheric or spherical-can be less than $10,000. Once amortized, the customer benefits from lenses ranging from $2 to $10 per piece, depending on the material type and production volumes. Tooling and parts cost for lenses at the upper limits (60 mm diameter) of the process can be two to five times higher, whereas tooling and parts cost for G&P aspheric optics can be 10 to 40 times higher. Further savings from molding result from less waste, an important consideration when expensive optical glass types are required.

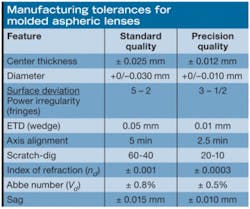

The glass molding process for aspheric optics has significantly improved in recent years-largely due to the advances in computer-numerically-controlled (CNC) machinery used to manufacture the tooling and measure the tools and optics. Surface profilometry and interferometric testing of transmitted and reflected wavefront shapes help to achieve “surface figure” accuracies of 1/4 wave (0.16 μm) or better (see table). The PGM process involves the forming of softened glass using heated molding tools of ground and polished silicon-carbide and other materials, sometimes with specially coated tooling surfaces, depending upon the softening point, Tg, and the chemical makeup of the glass or glassy ceramic used.

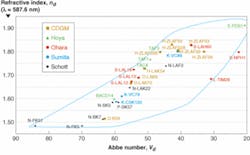

A variety of glass types can be used in the glass molding process. Most optical glass companies offer a dozen or more moldable glasses with low Tg (300°C to 550°C) properties (see Fig. 2). These glasses offer the designer good flexibility and typically transmit in the long ultraviolet to near infrared (IR) wavelengths (380 nm to 2.0 μm). Eastman Kodak and its successor Rochester Precision Optics (RPO) have developed processes that can precisely mold glasses with a Tg up to 800°C. This results in an even broader material offering for molding, giving the optical designer considerable flexibility and ease when converting traditional spherical systems into higher-performing aspheric designs. In doing so, however, the designer must ensure the lens design uses the molded glass refractive-index values that are slightly lower than that of the raw glass in strip or block form. These “index drop” values can be found in the glass libraries of most lens design software packages such as ZEMAX and Code V (or are readily provided by most PMG manufacturers).

The PGM process is not limited to small optics. For the right element geometry, it can enable economical production of aspheric lenses up to 60 mm in diameter and more than 20 mm thick. Additionally, IR glasses such as chalcogenide that transmit at wavelengths as long as 14 μm are routinely molded, replacing more expensive diamond-turned IR materials such as germanium, silicon, zinc sulphide, and zinc selenide in thermal imaging and other IR applications. Lens designers have provided the following case studies to share details of how they developed cost-effective design solutions.

Night-vision goggles

A customer asked an optical designer to optimize a six-element (four spherical and two G&P aspheric lenses) night-vision-goggle objective design.

The leading drivers for night-vision goggle designs are typically weight and performance. The incorporation of the two aspheres allowed the goggles to have relatively few elements-an equivalent all-spherical solution would have required an additional element to meet the same performance specifications, which would have driven the system to an unacceptable weight. Unfortunately, the two G&P aspheres were prohibitively expensive and unsuited for higher-volume production (an eventual goal of the customer). The challenge was to dramatically reduce the cost, while at the same time holding (or improving) the performance and preserving (or reducing) the system weight.

Fortunately, the list of moldable glass materials is continually expanding and extensive. Working with this large selection, the designer was able to find moldable materials roughly equivalent to the G&P aspheres and incorporate them into the goggle optics with no increase in system weight and with comparable performance. With further system optimization, the aspheric elements were reduced to one, reducing the cost even further. Key to this further optimization was an intimate understanding of the capabilities and restrictions of the glass molding process, which are unique to each manufacturer and very different from those of more traditional optical fabrication methods.

IR LEDs

A customer hired a designer to optimize the collimating optics for a broad-area IR-light-emitting diode (IRED) with ± 0.5° divergence error, dominated by the 0.2 mm size of the LED die. The overall length from front vertex of lens to the IRED die had to be less than 6 mm and the outer diameter less than 5 mm to fit available space.

The size of the IRED die and the allowed divergence in the collimated output dictated a lens with a focal length of 12 mm. A simple collimator lens fit within the 6 mm space, but introduced a manufacturing problem. The lens design would need to be f/2.5 and free of spherical aberration to satisfy the beam divergence rerquirement. The use of high-index optical materials would minimize surface curvature.

The designer realized that it would be impossible to satisfy these IRED collimation requirements using conventional G&P spherical surfaces at f/2.5. At least one aspheric surface would be required to sufficiently eliminate spherical aberration-which called for single-point diamond-turned (SPDT) manufacturing.

The consultant considered an SPDT aspheric singlet of zinc selenide (ZnSe; index of 2.52). However, of the six vendors solicited, only one vendor responded-with an extremely high cost and painfully long delivery. The diamond-turning process would require a new single-point tool to machine the concave surface feature, which was a steep radius on a clear aperture just 0.5 mm in diameter. This justified some of the added cost, but introduced risk by pushing the SPDT manufacturing process beyond its limits.

If the designer specified a ZnSe diamond-turned positive-meniscus lens element, it would need to be paired with a G&P biconcave spherical lens of N-SF57 (high-index 1.845 optical glass). In all, this solution proved more costly than the original thick singlet because of tight lens spacing tolerance, added high-precision mechanical components costs, and a more complicated doublet lens assembly.

Precision glass molding methodology allowed another look at a viable thick-lens solution based on Hoya E-FDS1 glass with a refractive index of 1.913. The design required modification of the sharp and nearly hemispherical 0.61-mm-diameter concave surface feature and also required a tight tolerance on the center thickness. This option avoided the assembly complications of an air-spaced doublet, and eliminated more costly diamond turning and expensive ZnSe altogether.

Precision glass molding offered low tooling cost and rapid delivery compared to ground-and-polished or diamond-turned approaches. The cost in small prototype quantities of 100 pieces was competitive with ground-and-polished lenses (and far better in production quantities). Furthermore, the design constrained the rear surface to a flat shape, which simplified the post-molding metrology while saving time and cost. Overall, the PGM process provided lower cost, faster delivery, and lower-risk than the other strained optics solutions that were on the verge of “unobtanium.”

Tell us what you think about this article. Send an e-mail to [email protected].

EDWARD PATTON is director of sales and marketing at Rochester Precision Optics, 850 John St., West Henrietta, NY 14586; e-mail: [email protected]; www.rpoptics.com. DAVID STITES is an optical consultant and designer at Total Optic Solutions, 8401 Ninth Street North, Suite 250, St. Petersburg FL 33702; dstites@totalopticsolutions. SCOTT CAHALL is an optical consultant and designer at Moondog Optics, 264 Village Landing, Fairport NY 14450; [email protected].