MICROSTRUCTURE FIBERS: Photonic-crystal fibers move out of the laboratory

CHRIS EMSLIE

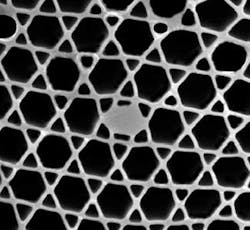

Since its inception, microstructure or photonic-crystal optical fibers have demonstrated properties that could enable them to replace more conventional and established specialty fibers in a number of key applications.1 Although there has been much debate about the precise mechanism by which this class of fibers work, it is now generally accepted that, in most cases, guidance is created because the microstructure of air gaps within the cladding creates an average refractive index that is significantly lower than that of the (typically) solid silica core. For this reason, the original classification of “photonic crystal” or “photonic bandgap” has given way to “microstructure” or—even the more prosaic—“holey fiber” (see Fig. 1).

The fabrication technique for microstructure fibers bears little resemblance to any other specialty fiber for the simple reason that it does not rely on direct, modified chemical-vapor deposition (MCVD) to create the preform. Successful manufacture of specialty-fiber or polarization-maintaining (PM)-fiber preforms using MCVD relies on manipulation of vapor flows in combination with either gas-phase etching or ultrasonic machining, while with a microstructure fiber the critical factor is the precision assembly of the individual components.2

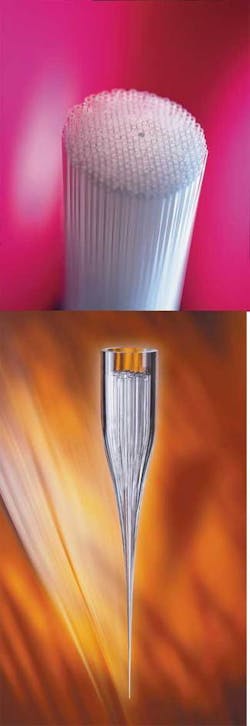

Microstructure-fiber preforms are fabricated by building a close-packed arrangement of silica tubes around a central silica rod or tube that together replicates the desired fiber structure. Precision-machined jigs are used to facilitate this process and the completed preform is typically held together with platinum wire during drawing. Exceptional precision is essential during the assembly of the preform, together with fine control of all drawing conditions to ensure that viscous forces do not distort the fiber during formation and preserve the integrity and geometry of the structure. While MCVD is not used directly to create the preform, the process can still be used to fabricate the high-purity, fused-silica components that make up the preform (see Fig. 2).Benefits of microstructure fiber

One of the benefits of microstructure fiber is derived from the fact that its structure is formed from a single material—typically silica—so there are none of the thermal stress problems associated with conventional fibers having a doped silica core and a pure silica cladding. As a result, the fundamental transmission characteristics of a microstructure fiber are typically unaffected by even large variations in temperature. This attribute is of particular interest in fiber sensors, in which intrinsic and universal sensitivity to temperature can easily mask the effects of measurement parameters and thereby render the sensor either useless, overcomplicated, or in some cases, both.

Microstructure design can also offer benefits in interferometric fiber sensors because of its exceptional degree of birefringence—and therefore polarization-maintaining ability—that has been demonstrated in the laboratory. It is ironic that the original elliptical-core form of birefringent PM fiber technology has now been sidelined in favor of stress birefringent designs because PM microstructure fibers are, in fact, form birefringent. These PM fibers take advantage of the very high index difference that can be created using an air/silica composite cladding, in combination with a highly elliptical, pure silica core to generate correspondingly high values of birefringence—up to an order of magnitude greater than has been achieved from conventional, stress-birefringent designs.3, 4

Microstructure fibers can also bring benefits when used to create cladding pump or “dual clad” fibers for high-power laser and amplifier applications. The majority of cladding pump fibers in use today are of a composite silica/polymer construction and have the advantage of relatively simple fabrication and a high multimode numerical aperture (NA) that facilitates the optical combination of several high-power pump diodes using tapered bundles. However, these composite polymer/silica fibers raise questions with respect to reliability, robustness, and ease of use. Fibercore has adopted an alternative approach with fibers that are all-silica in construction—offering superior handling and lifetime characteristics when compared with the hybrid silica/polymer designs—but with the tradeoff of a slightly lower NA. The microstructure fiber, in comparison, can demonstrate all the performance benefits of the composite silica/polymer fiber as well as the potential ease of use and reliability that comes from its all-silica construction.

Challenges of microstructure fiber

Overall, for specialty-fiber applications, microstructure fibers have huge potential advantages over conventional fibers. However, despite these theoretical advantages, potential users have been slow in their uptake for several reasons.

To date, the fibers have been difficult to splice because of the complexity of the structure and often fusion splicing will dictate whether a fiber can be used in a practical circumstance. Original-equipment manufacturers are also naturally nervous about using fibers with voids inside them. Another significant obstacle is that the true optical loss of the fibers has historically been quite large. In theory, microstructure fibers should demonstrate far lower optical losses than conventional fibers; in practice, however, they exhibit losses an order of magnitude higher. In a case in which a conventional fiber is demonstrating a loss of less than 1 dB/km, microstructure fibers can be expected to show a loss of between 8 and 10 dB/km. To date, no one has been able to demonstrate performance anywhere close to what the theoretical limit should be and, not surprisingly, many experts have theorized without consensus as to why microstructure fibers have not delivered the expected performance.

The lack of availability of components—which goes hand-in-hand with the relative immaturity of the technology—also serves to restrict the penetration of these products and maintain them as promising technical curiosities, but technical curiosities all the same.

Moving beyond technical curiosity

On the basis that microstructure fibers have potentially superior performance over the fibers currently available, what set of circumstances will propel microstructure fiber from technical curiosity to killer technology? One answer to this vexing question can be found by looking at Fibercore’s own history of specialty-fiber development.

In 1996, Fibercore optical fibers were in a very similar situation during their early years of development with a huge amount of potential waiting to be tapped. As well as addressing the fundamental performance issues that were identified, we found it was vitally important to consider that the fiber must also be robust enough to be manipulated and jointed in a commercially viable manufacturing process. However, we also realized that components, infrastructure, and ancillary products needed to be developed in sync with the fiber to make the product successful.

A technology often doesn’t fail because of its core, but invariably because of the quality or availability of ancillary products. If the support is not there to implement that technology in a practical way, the technology will fail. Without the availability of components—no matter how well the fiber works—there is very little value, as it cannot be applied to commercial applications. Exactly the same is true for microstructure fiber today. To be accepted and widely used, components and ancillaries are needed to bring the whole product closer to maturity. Then and only then, will microstructure fibers start to deliver their true potential.

REFERENCES

1. P.J. Bennett, T. M. Monro, and D. J. Richardson, Optics Letters 24, 17, 1203 (Sept. 1, 1999).

2. A. Mendez and T.F. Morse, editors, Specialty Optical Fibers Handbook, Elsevier ISBN 012369406X (2006).

3. K. Suzuki et al., Optics Express 9(13) 676 (Dec. 17, 2001).

4. S.B. Libori et al., IEEE Photonics Tech. Lett. 13, 588 (2001).

Chris Emslie is managing director of Fibercore (a wholly owned subsidiary of Scientific-Atlanta of Lawrenceville, GA), Fibercore House, University Parkway, Chilworth Science Park, Southampton, England SO16 7QQ; e-mail: [email protected]; www.fibercore.com.