FIBER OPTICS: Optical transceiver goes where copper cannot

A new 40 Gbit/s optical active cable (OAC) is the first on the market to monolithically incorporate active optics for data communications manufactured with low-cost silicon-based chip processing. Fiber-to-the-chip company Luxtera (Carlsbad, CA) claims its “Blazar” OAC is the first complementary-metal-oxide-semiconductor (CMOS) silicon-photonics product, a significant development that enables high-volume manufacturing, and thus lower cost, of high-bandwidth optical-data modules.

The OAC is a single-mode fiber-optic cable assembly that interconnects servers, computer clusters, and switches with four channels per cable, each transmitting up to 10.55 Gbit/s signals for 300 m without regeneration or amplification. While copper cable assemblies are efficient and cost-effective for distances of less than 10 m, they cannot transmit signals for more than 10 m at serial speeds of 10 Gbit/s without transceivers and amplifiers, which add to cost, bulk, and maintenance.

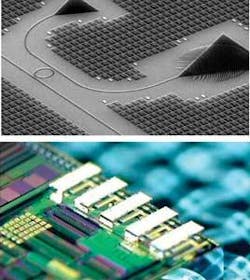

Previous optical-module assemblies have been able to transmit signals for hundreds of meters without regeneration, but the cost to manufacture them in high volume made them impractical. By coupling detectors, electronics, lasers, modulators, and waveguides in one monolithic CMOS chip (manufactured using standard CMOS-processing techniques), high-volume manufacturing brings the cost of a 40 Gbit/s OAC down to that of a 20 Gbit/s unit.

On-chip photodetectors incorporate a thin-film layer of germanium next to the silicon-based waveguide to enable the optically clear transceiver to “see” the transmitted 1.5 µm signal (see www.laserfocusworld.com/articles/292384). This approach boasts a bit-error rate for the complete receiver of 10-12, and brings the price of detector manufacturing down by a couple of magnitudes. Luxtera will incorporate this technology in its future products, further reducing transceiver costs.

Fiber-optic assemblies have typically required careful handling to protect the fiber from debris, moisture, and scratches that degrade signal strength. The integrated design of the Blazar permanently attaches the fiber directly to the top of the chip via holographic lenses that couple the light at approximately a 90° angle, creating a hermetically closed optical system that handles like rugged copper cable while significantly cutting the cost of connectors at each coupled end by $40. A top-of-the-chip fiber-coupling design also enables wafer-scale optical testing and eliminates the possibility of light loss at the connector. Finally, the top-coupled fiber enables flip-chip-mounted lasers; a single continuous-wave laser powers four transmitters and the complete transceiver consumes 2.2 W of power per 40 Gbit/s chip.

A spinoff of the California Institute of Technology (Pasadena, CA), Luxtera plans to target the high-performance-copper computing market (Infiniband), followed by Fibre Channel and Ethernet. The company will provide samples to its development partners in late 2007. General sampling is scheduled for early 2008, with production to start in mid-2008.

About the Author

Valerie Coffey-Rosich

Contributing Editor

Valerie Coffey-Rosich is a freelance science and technology writer and editor and a contributing editor for Laser Focus World; she previously served as an Associate Technical Editor (2000-2003) and a Senior Technical Editor (2007-2008) for Laser Focus World.

Valerie holds a BS in physics from the University of Nevada, Reno, and an MA in astronomy from Boston University. She specializes in editing and writing about optics, photonics, astronomy, and physics in academic, reference, and business-to-business publications. In addition to Laser Focus World, her work has appeared online and in print for clients such as the American Institute of Physics, American Heritage Dictionary, BioPhotonics, Encyclopedia Britannica, EuroPhotonics, the Optical Society of America, Photonics Focus, Photonics Spectra, Sky & Telescope, and many others. She is based in Palm Springs, California.