SUPERCONTINUUM SOURCES: New white-light supercontinuum sources have no blue deficiency

JOHN CLOWES and JONATHAN KNIGHT

In the past decade, the invention of highly nonlinear photonic-crystal fibers (PCFs) and the development of compact, high-power ultrafast fiber lasers have enabled turnkey white-light laser sources with powers approaching 10 W and spectral power densities as high as 10 mW/nm.

While these commercial fiber-supercontinuum sources show potential in industrial and biomedical applications, they all have a common deficiency in the blue region of the spectrum. With spectra spanning down to 450 nm in only the highest specification systems, the fiber-supercontinuum laser still has restricted presence as an alternative illumination source.

However, recent developments in nonlinear PCFs by researchers at the University of Bath have identified the cause of blue deficiency in supercontinuum fiber lasers, resulting in an output enhanced at blue wavelengths (see Fig. 1); this technology development is now being commercialized by Fianium.

The white-light laser

The temporal coherence of lasers corresponds to their limited spectral width, which arises fundamentally because of the finite gain bandwidth of all materials. Even the broadest gain curves provide gain only over 10% to 20% of the central frequency.

However, many applications demand greater spectral bandwidth without loss in brightness or power. One way to generate the extra spectral width is to exploit the nonlinear optical response of materials at high optical powers; white-light laser sources based on this technique have been known almost since the invention of the laser.1 Most early configurations required large and cumbersome pump-laser systems; many experiments used bulk materials as the nonlinear element. But the same nonlinear processes that generated the broadband light typically also reduced the quality of the output beam due to filamentation and beam breakup.

A breakthrough came with the rapid development of photonic-crystal and microstructured optical fibers, in which light is guided in a solid silica core by surrounding it with tiny air holes. These fibers were used to generate broad supercontinua with high beam quality at visible wavelengths using a bulk Ti:sapphire laser as a pump source.2 This led to a period of rapid technological progress as researchers tried to understand the essential features of the processes while optimizing the system (pump laser coupled with nonlinear fiber) to give broad, flat, low-noise spectra using low-cost pump components. The interest was driven by a range of potential applications that could benefit from, or be enabled by, a light source that was in several ways fundamentally different from those that had existed previously.

The fiber-supercontinuum phenomenon

How does a narrowband laser beam get transformed into a brilliant rainbow of colors spanning the visible and near-infrared simply by passing it through a fiber made of plain silica?

The details of the process are complicated, and vary depending on the wavelength, the pulse length, and the fiber being used. In common to virtually all configurations, however, are the contributions from the Kerr and Raman nonlinearities, and the significance of the group-velocity dispersion (GVD). If the GVD is normal, then the Kerr and dispersive terms both serve to disperse the pulse, so that the peak intensity drops and the nonlinear response of the fiber is greatly reduced after propagation through only a short fiber length. As a result, the spectral broadening in this case is only modest.

However, if the group velocity is anomalous (that is, the group index increases with wavelength) then the effects of GVD and Kerr nonlinearity counteract one another, and pulses can travel long distances down the fiber as optical solitons, without dispersing. The long propagation distances with high peak intensity opens the door to a range of optical effects that lead to further spectral broadening, and ultimately to efficient supercontinuum generation. This ability is part of the reason that photonic-crystal fibers are so effective: they allow the zero-GVD wavelength to be manipulated over a broad range, and enable anomalous wavelengths corresponding to those emitted by popular pump lasers, such as 1064 and 800 nm, which is is simply not possible using conventional fiber technology.Group-index matching: overcoming the blue deficiency

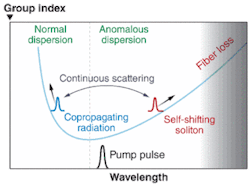

We now understand that the blue edge of the supercontinuum is frequently set by a relatively simple condition (see Fig. 2).3 The fiber is pumped close to the zero-dispersion wavelength, but on the anomalous-dispersion side. The pump pulse generates solitons, which undergo a Raman self-frequency shift as they propagate, and hence move to longer wavelengths. The pump pulse also generates radiation at shorter wavelengths in the normal-dispersion regime. Because of the shape of the group-index curve, and because the pump is close to the minimum in the curve, radiation on the short and long-wavelength sides of the pump propagate with the same group velocity. As a result, they interact through four-wave mixing as they propagate. This interaction, combined with the Raman self-frequency shift of the infrared solitons, causes the short-wavelength radiation to continually shift toward the blue (see Fig. 3).Eventually, the infrared solitons shift no more, perhaps because they move into the high-attenuation region of the fiber. In most PCFs, this occurs around the 2.5 µm wavelength, due to the presence of OH (hydroxyl radicals) in the fiber core. When the infrared pulse is absorbed or scattered, there is no mechanism to drive the short-wavelength radiation to still shorter wavelengths. As a result, for a given fiber, there is a natural minimum wavelength to be generated by this mechanism. This shortest wavelength is that which shares the same group index as that at which the long-wavelength solitons are heavily attenuated.

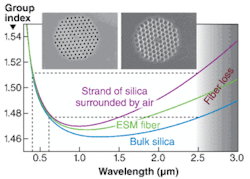

Most commercial high-brightness supercontinuum lasers rely on an ultrafast fiber laser operating at approximately 1064 nm to pump the PCFs. As a result, the PCFs used in these systems are designed to have the zero-GVD wavelength very close to the 1064 nm pump wavelength. Such fibers have been the intuitive choice for generation of 1064-nm-pumped supercontinua (see Fig. 3, left inset). Often referred to as “endlessly single-mode” (ESM) PCFs, these fibers provide a zero GVD in the 1030 to 1060 nm range while also producing a waveguide geometry guiding only the fundamental mode over the entire spectrum of the supercontinuum.

Based on our new understanding of supercontinuum generation in PCFs, the ESM fiber is not the optimal fiber design, because the shape of the GVD curve limits the short-wavelength edge of the resulting supercontinuum to between 450 and 500 nm. However, by changing the design of the fiber being used (see Fig. 3, right inset) one can devise structures that will generate shorter wavelengths within the supercontinuum.

This new understanding changes the PCF design goals. Instead of optimizing the zero-GVD wavelength and targeting an endlessly single-mode waveguide design, the new approach aims for optimization of the GVD curve across the entire spectrum from the ultraviolet to the infrared beyond 3 µm. The size of the fiber core is required to be around 5 µm, due to the requirement for the zero-GVD wavelength to be reasonably close to the pump wavelength at 1.06 µm. The air filling fraction, however, is a free parameter, and the shortest wavelengths are generated by the fiber with the highest air filling fraction—most closely approximating a thin strand of silica suspended in air.

The results are visibly impressive; between 50 and 100 nm additional blue and UV spectral components are generated within the supercontinuum of new fiber designs compared to conventional, commercially available ESM nonlinear fibers.

Turnkey solutions

The natural choice of pump-laser source for efficient and reliable supercontinuum generation is the high-power ultrafast fiber laser, capable of operating at megahertz pulse-repetition rates and at power levels as high as tens of watts. The all-fiber configuration means that coupling of the pump to the PCF can be achieved through splicing of optical fibers, which is inherently reliable. Furthermore, exploiting the efficiency of ytterbium-doped fiber amplifiers, these sources operate in the spectral range between 1 and 1.1 µm, making them suitable for pumping of nonlinear PCFs.

The synergy between high-power ultrafast fiber lasers and nonlinear PCFs has resulted in assignment of the University of Bath technology to Fianium. Photonic-crystal-fiber designs, based on the University of Bath technology, are being fabricated by third-party PCF manufacturers and integrated into turnkey commercial supercontinuum fiber-laser sources (see Fig. 4).The new systems now offer access to the entire spectral range from below 400 nm (as low as 380 nm has been recently demonstrated) to approximately 2400 nm with milliwatts per nanometer spectral power densities and with diffraction-limited output.

The region of the spectrum from 450 nm down into the UV is extremely important for many fluorescence-imaging applications, and for applications conventionally utilizing arc-lamp illumination sources, where the turnkey blue-enhanced supercontinuum source now offers a reasonable comparison in spectrum but with orders of magnitude increase in brightness.

The ultraviolet challenge

Power scaling of the supercontinuum source and pushing the supercontinuum spectrum into the UV toward 300 nm are the next goals in development projects between the University of Bath and Fianium. Efficient conversion of power from the pump band into the ultraviolet remains a challenging goal. Issues with PCF designs and material investigations in the presence of high-energy UV photons will offer challenges in supercontinuum fiber laser developments over the coming 12 months.

REFERENCES

- R.R. Alfano et al., Phys. Rev. Lett. 24, 854, (1970).

- J.K. Ranka et al., Optics Lett. 25(1) 25, (2000).

- J.M. Stone et al., Optics Express 16(4) 2670, (2008).

Editor’s note: John Clowes will speak on technology and markets for supercontinuum lasers at the Lasers and Photonics Marketplace Seminar Jan. 26, 2009, in San Jose, CA. For more information, see www.marketplaceseminar.com.

John Clowes is director of business development for Fianium, 20 Compass Point, Ensign Way, Hamble Southampton, England; e-mail: john.clowes@fianium.com; www.fianium.com and Jonathan Knight is head of the Department of Physics and a member of the Centre for Photonics and Photonic Materials, University of Bath, Bath, England.