LAURENT VAISSIÉ, TOM STEELE, and PAUL T. RUDY

The most common application of high-power diode lasers is to pump the gain media of solid-state and fiber-laser systems. Over the last two decades, the availability of high-power diode pumps at wavelengths like 808 nm has enabled enormous improvements in laser-system operating efficiency and compactness compared to traditional lamp-pumped lasers. However, those diodes have otherwise not been optimal for the broadening array of pump applications. Specifically, diodes have had only moderate spatial brightness, a limited range of wavelengths available, and poor spectral stability requiring precise temperature control, which adds complexity and cost.

Recent advances in diode efficiencies have improved the performance of diode-pumped lasers, and pumps with higher spatial brightness have enabled rapid deployment of fiber lasers. Additionally, new pump wavelengths have emerged to enable pumping of novel laser media, as well as superior laser performance of established media. More recently diode pumps with on-chip gratings that stabilize the wavelength have been developed, offering the “athermal” performance of lamp pumping with the high efficiency of diode pumping. Innovators have also made numerous refinements in diode epitaxial structure designs, regrowth techniques, and material systems configurations, enhancing diode suitability for a variety of exciting new pumping applications.

Together, these pump-diode advances are enabling dramatic improvements in laser-system compactness, efficiency, power, and beam quality, while at the same time reducing thermal management, cost, and complexity in the system.

Higher efficiency

Substantial progress has been made over the last several years in improving the electro-optical efficiency of aluminum gallium arsenide (AlGaAs) diode lasers. Government-sponsored programs in the U.S. and Europe, as well as privately funded initiatives by several manufacturers have increased the electrical-to-optical efficiency of commercial off-the-shelf high-power diode lasers from the 40% to 50% range to the 50% to 60% regime. Devices with high efficiency of more than 70% have been demonstrated in the lab and are expected to be released commercially in the near future. In the U.S., for example, the DARPA-funded Super-High-Efficiency Diode Sources (SHEDS) program was launched in the fall of 2003. It was motivated by the desire to improve the efficiency of high-power diode-pumped laser systems, which can intrinsically be quite efficient if the pump-diode efficiency is high. The program involved eight partners from industry and academia aiming to fabricate diode lasers with 80% electrical-to-optical efficiency. While the participants in that program focused efforts on 976 nm, other related efforts in this arena have increased the efficiency of 808 nm devices as well.

Spatial brightness

Single-emitter technology based on volume manufacturing developed for telecommunications has produced an increase in diode brightness. Today, several companies offer 10 W of power from a 100-µm-core fiber at 915 or 980 nm with low numerical aperture while integrated single-emitter arrays achieve 350 W out of a 200-µm-core fiber.

At 808 nm, the photon energy is higher, and the risk of catastrophic optical damage increases. New passivation techniques based on regrowth technology allow quasi-CW (QCW) operation of fiber-coupled devices as high as 100 W out of a 400 µm core fiber from a low-fill-factor single-bar device. For free-space applications, progress in hard-solder technology and diode efficiency also enable high-fill-factor bars (50%) to reach 300 W at 808 nm and over 1 kW at 980 nm.

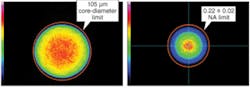

Pump-diode manufacturers have also improved brightness from fiber-coupled modules with “cladding-free” power for fiber-laser pumping, enhancing conversion efficiency and limiting risks of damage for pump combiners (see Fig. 1).

Extending reach

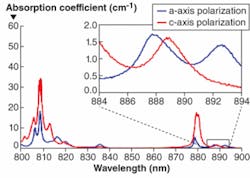

The 808 nm band has traditionally been the workhorse pump wavelength for neodymium (Nd)-doped solid-state crystals. More recently, demand for 915, 940, and 980 nm fiber-coupled diodes has increased for pumping fiber lasers. In addition, new wavelengths have been developed to enhance diode-pumped solid-state laser efficiency and performance. Pumping Nd:YVO4 (vanadate) for example, at 888 nm accesses a low and isotropic absorption region, with equal coefficients for both states of polarization as well as higher efficiency from a reduced quantum defect between the emission and absorption wavelengths. This allows for reduced thermal load effects and eliminates the sensitivity to pump polarization, so flexible delivery of the pump light through a multimode fiber can be used (see Fig. 2).1Improved diode growth techniques and new passivation technology have enabled 792 nm pumps for eye-safe thulium fiber lasers. Record efficiencies of 65% were recently achieved due to unique material interactions when pumping around 792 nm, effectively exciting two thulium ions with a single-pump photon. Today, 792 nm high-brightness pump lasers up to 50 W coupled into 100-µm-core fibers are commercially available.

In the eye-safe regime, wavelength-stabilized high-power diodes at 1532 nm are replacing fiber-laser pump sources, enabling erbium (Er)-doped YAG high-power lasers with low quantum defects.2 Pump diodes with up to 90 W from a 400 µm fiber core and 700 W from a 25-bar stack with reduced temperature sensitivity are now available.

Athermal pumping

Emerging nanosecond and ultrafast fiber lasers based on ytterbium (Yb)- or Er:Yb-based materials require high absorption per unit length at 976 nm to minimize nonlinearities and improve conversion efficiency.3 However, absorption at 976 nm is narrow and requires pumping with accurate center wavelength, narrow bandwidth, and stability versus temperature. Several promising materials for high-power thin-disk lasers such as Yb:lutetium oxide (Yb:Lu2O3) or alkali-vapor lasers also rely on such pump-diode performance to unleash their potential.

In high-power CW applications, system designers look for a reduction of the quantum defect to operate with less heat dissipation, lower risk of catastrophic damage, and enhanced conversion efficiency. However, such preferred wavelengths often have narrow absorption bandwidths and require pumping with narrow emission linewidth as well as accurate center wavelength, such as 1532 nm for Er:YAG. Quasi-CW operation of pump diodes also benefits from a reduced wavelength-temperature coefficient, limiting thermal effects linked to steep variation in drive current and maintaining a narrow bandwidth required for efficient pumping. Finally, defense and portable consumer-electronics applications require pump diodes to maintain accurate center wavelength during operation despite temperature variations as high as 80°C. Improving the stability and the spectral narrowing of high-power laser diodes is therefore critical so that they can simultaneously deliver the efficiency associated with diode pumping and temperature-insensitivity provided by lamp pumping.

Wavelength stabilization

Various methods have been tested to improve the spectral brightness, stability, and accuracy of laser diodes. These approaches include external components using volume Bragg gratings, fiber Bragg gratings, or external lenses with bulk gratings. For instance, emission based on external volume-Bragg-grating stabilization typically provides very narrow linewidth (less than 0.1 nm) and a low wavelength-temperature coefficient, typically on the order of 0.01 nm/°C, with up to 90% of the power locked in a narrow spectrum.

However, approaches based on external components require sensitive and high-precision alignment, costly additional optics, and specially designed diode facet coatings. Also, the operation of the laser diode is restricted to a narrow current range to maintain wavelength locking due to the gain-peak shift of the diode versus current. Finally, the locked bandwidth may actually be too narrow for pumping some solid-state materials, saturating the gain and limiting the output power.

Recently, lasers with grating devices have helped overcome these challenges for high-power lasers over a broad range of wavelengths from 792 to 1550 nm.4 These metal-organic chemical-vapor-deposition-grown gallium-arsenide-based and indium-phosphide-based lasers include internal gratings that narrow the spectral linewidth to less than 0.2 nm, reduce wavelength-temperature sensitivity to less than 0.1 nm/°C, and ensure that the device operates at the required wavelength. These devices are fabricated using a wafer-based process, with the gratings defined after a first epitaxial growth by optical lithography into a photoresist layer, followed by etching, then finalized during a regrowth process.High-performance diodes

Efficient pumping of alkali-vapor lasers such as rubidium or cesium is one of the most demanding pumping applications for laser diodes due to a very narrow absorption line (approximately 10 GHz). Recently, spectral linewidth as narrow as 30 pm was obtained by locking a 30 W laser-diode bar at 780 nm with a volume Bragg grating, reporting 85% absorption of the laser radiation.5

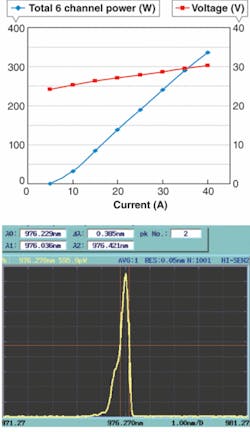

For high-peak-power fiber lasers, wavelength-stabilized, high-brightness, fiber-coupled modules at 976 nm are now available commercially, offering a dramatic reduction of the wavelength temperature coefficient from 0.3 nm/°C to 0.074 nm/°C. Similarly, the center wavelength accuracy as a function of applied current is measured at 0.089 nm/A, showing great promise for QCW operation of these devices (see Fig. 3). Internal gratings also enable high-temperature operation of pump diodes with center wavelength locked and tuning at only 0.07 nm/°C up to at least 60°C.Diode-laser pump sources are far from mature, and continue to evolve to better suit the challenges of a broadening range of diode-pumped laser applications. Recent breakthroughs in single-emitter brightness, wavelength stabilization, and new wavelength availability offer a wide and unprecedented palette to laser-system designers.

REFERENCES

1. L. McDonagh et al., Proc. SPIE 6451, 6451-0F (2007).

2. S.D. Setzler et al., IEEE J. of Selected Topics in Quant. Electronics 11(3) (2005).

3. C.D. Brooks and F. Di Teodoro, Optics Express 13(22) (2005).

4. P.T. Rudy, Compound Semiconductors 12(7) (August 2006).

5. A. Gourevitch et al., paper MC12, Advanced Solid Sate Photonics conf., Nara, Japan (2008).

PAUL RUDY is vice president of marketing and sales, TOM STEELE is director of market development, and LAURENT VAISSIÉ is product manager at QPC Lasers, 15632 Roxford Street, Sylmar, CA 91342; e-mail: [email protected]; www.qpclasers.com.