A green-emitting optically pumped semiconductor laser (OPSL) introduced on June 12 by Coherent (Santa Clara, CA) is potentially a big deal in the scientific-laser marketplace, and for one reason in particular: the 5 W, 532 nm version of the Coherent OPSL looks to be a very low-noise source for pumping Ti:sapphire ultrafast lasers, and at a much lower cost than equivalent diode-pumped solid-state (DPSS) pump lasers. (The OPSL, whose 5 W version is called the Verdi G5, also comes in a 2 W version called the G2; however, that power level is a bit low for pumping Ti:sapphire lasers.)

The gain medium of the OPSL is a semiconductor chip containing indium gallium arsenide (InGaAs) quantum wells alternating with layers of gallium arsenide (GaAs). The GaAs layers absorb the pump radiation; the InGaAs quantum wells emit light at a wavelength determined by the quantum-well dimensions and relative proportions of indium and gallium. The gain medium is pumped with near-IR light from a diode array. The OPSL light can easily be intracavity frequency-doubled (or tripled); the resulting beam is single-spatial-mode, with an M2 of better than 1.1.

Pumping of Ti:sapphire lasers is conventionally done with neodymium-based DPSS lasers, which have multiple longitudinal modes and intracavity doubling—a combination that results in fluctuating power distributions between the modes, or “green noise.” Such intensity noise can be reduced in a DPSS laser by use of line-narrowing optics, stabilization loops, and precise control of cavity temperature.

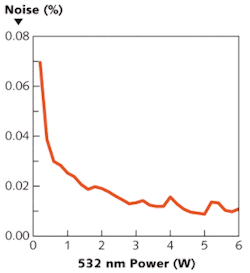

In contrast, OPSLs intrinsically do not exhibit green noise, due to the short excited-state lifetime of the OPSL gain medium. With no stored gain, there are no dynamic fluctuations and the longitudinal-mode pattern is thus entirely determined by the characteristics of the laser cavity. As a result, the Coherent 5 W OPSL has an RMS noise of less than 0.03% over a 10 Hz to 100 MHz bandwidth (see figure).

Other scientific uses

The green OPSLs (along with other OPSLs made by Coherent that emit at various wavelengths from 355 to 577 nm) are also suitable for other scientific uses such as spectroscopy, holography, interferometry, carrier-envelope-phase stabilization, and atom cooling and trapping. Brandon Morioka, product-line manager at Coherent, notes that other central qualities of the OPSL technology are power-scaling ability (due to lack of thermal lensing) and wavelength flexibility. “Researchers used to revolve around wavelengths that were available from gas, dye, or DPSS elements and work around the closest fit,” he says. “Now, OPSLs can break down these barriers and allow researchers to find the best wavelength to fit their application.”

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.