RAMAN SPECTROSCOPY: Nanowire on a film makes efficient SERS platform

Researchers from KAIST (Daejeon, Korea), Korea University, and Soongsil University (both in Seoul, Korea), have developed an efficient and highly reproducible surface-enhanced Raman spectroscopy (SERS) platform for scattering-based sensors in biological and medical applications.1

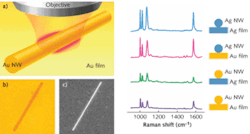

In SERS, molecules of interest adsorb onto particular nanostructured metal surfaces and create localized surface plasmons that cause a dramatic increase in the incident electromagnetic field–high Raman intensities that can be used to differentiate the spectral fingerprint of many molecules. Unfortunately, these high Raman intensities or “hot spots” are not easy to reproduce and are highly dependent on the nanostructure platform used. To combat this drawback, the research team developed a simple platform consisting of a metallic nanowire cast onto a metallic film. The single-nanowire-on-a-film (SNOF) architecture is easy to fabricate, reproducible, and provides a line of SERS hot spots at the gap between the nanowire and the film upon optical excitation. In addition, the position of the hot spots can be located in situ using an optical microscope during the SERS measurement.

“SNOF provides an important step toward our main goal to develop simple and atomically well-defined SERS-active nanostructures that actually could be applied as nanobiosensors,” says Ilsun Yoon, postdoctoral researcher at KAIST.

Both finite-difference time-domain (FDTD) modeling and experimental results were used to show how the SNOF architecture could increase Raman gain for improved spectral analysis of three different molecules: benzenethiol, brilliant cresyl blue, and single-stranded DNA. Experimentation included a gold (Au) nanowire fabricated on a Au film as the primary SNOF structure; in addition, a Au nanowire on a silicon substrate was used as a control platform to highlight the Raman gain observed for the primary SNOF structure. Silver (Ag) nanowires and films were also prepared in order to understand the effects of using different metals.

Gold nanowires were grown on a sapphire substrate in a horizontal quartz tube furnace using a vapor-transport method. The single-crystalline Au nanowires have a diamond-shaped cross section, are 100 to 200 nm in diameter, and up to tens of micrometers long. Gold 300-nm-thick films were deposited on 10 nm of chromium over silicon substrates, with electron-beam-assisted deposition. A root-mean-square surface roughness of 2.3 to 2.8 nm was sufficiently smooth for the films to be SERS inactive by themselves. To prepare the SNOF structure, Au nanowires were incubated in the solutions containing the analytes and then a drop of the incubated Au nanowire solution was cast on the Au film. The Au nanowires physically adhere on the Au film by the so-called “London force,” a form of intermolecular force.

Surface-plasmon polaritons

A home-built micro-Raman system with a cooled CCD detector and 500-nm-diameter helium-neon laser spot was then used to perform SERS measurements on the adsorbed molecules on the SNOF structure, which was immersed in water. When the SNOF structure is illuminated, an enhanced electric field is induced at the gap between the Au nanowire and the Au film due to excitation of a surface plasmon on the nanowire, which in turn excites surface-plasmon polaritons on the metal film, creating a hot line at the nanowire/film gap.

Experimental results indicated that the SERS signal increased by a factor of 500 for the Au nanowire on Au film SNOF compared to the Au nanowire on the silicon control substrate. Polarization of the input laser source was also important for Raman enhancement. Raman enhancement of SNOF is mainly dependent on the material of the nanowire. The Ag nanowire on Ag film SNOF had the best performance among the SNOF structures, because the localized surface-plasmon excitation of a Ag nanowire is stronger upon illumination by 633 nm laser light than that of a Au nanowire.

REFERENCE

- I. Yoon et al., J. American Chem. Soc. online, DOI: 10.1021/ja807455s (Dec. 19, 2008).

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.