JOSEPH SALHANY and BRYAN BURGOYNE

Suitably doped optical fibers can serve as a laser gain medium for a band of wavelengths when pumped with a higher-energy light source. But the typical doped fiber laser simply amplifies the input laser signal at its original wavelength. The use of a dispersive element together with a properly synchronized electro-optic modulator (EOM) yields a fully programmable fiber laser, giving the user electronic control over all the laser parameters, including wavelength, pulsewidth, and pulse repetition rate.

Evolution of the fiber laser

Shortly after the first laser was demonstrated in 1960, Elias Snitzer began working with glass as the laser medium and in 1964 demonstrated the first fiber laser. The fiber laser continued evolving and by 1987, David Payne introduced the first erbium-doped fiber amplifiers (EDFAs). Initial deployments of EDFAs occurred in long-haul optical telecommunications systems to extend the reach between nodes and reduce overall network cost.

Fiber laser evolution continued with the introduction of ytterbium (Yb) doping. In the 1 μm band, Yb-doped fibers serve as a highly efficient gain medium that can offer higher power conversion efficiencies and larger power levels than EFDAs. Such fibers are at the core of Yb fiber amplifiers as well as the high-power fiber lasers now used extensively in industrial, medical, and high-quality imaging applications.

Further advances in fiber technologies, optical component design, and control electronics are now driving fiber lasers farther into the mainstream. These lasers are more compact and rugged than the classic lasers and in many instances can replace legacy systems that are more costly to maintain and complex to operate. In addition, the compactness and robustness of fiber lasers allow them to address many new applications.

The latest innovations have enabled creation of fast-scanning pulsed fiber laser systems in the picosecond regime that offer improvements in quality and accuracy over nanosecond systems. One such picosecond system is the Synchronized Programmable Laser (SPL) from Genia Photonics that can combine two picosecond fiber laser systems with both output pulses synchronized at the target.

Synchronized and programmable

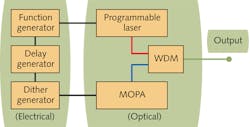

The SPL system consists of a programmable dispersion-tuned and actively modelocked fiber laser together with a fiber-based master oscillator power amplifier (MOPA). A wavelength-division multiplexer (WDM) coupler combines the two laser outputs into a single beam (see Fig. 1). The PL and MOPA use high-speed electronics to drive their internal EOM with precisely timed picosecond pulses. The root of the synchronization lies within a novel low-jitter function generator (FG) circuit capable of generating multiple signals to trigger the pulse generators of each laser. These signals are tunable to compensate for any delays in the external optical setup, ensuring that pulses from both lasers are synchronized at the target. The function generator also extends to provide external signaling to trigger other equipment such as acquisition and imaging systems. This external signaling includes a series of triggers that indicate events such as the start of the sweep cycle, the start of each consecutive sweep, each optical pulse generated, and each wavelength change.

Synchronized pulses of different wavelengths are paramount in nonlinear optics where both spatial and temporal overlapping is required. The ability to achieve overlapped laser pulses at two independent wavelengths opens the door to nonlinear imaging applications such as coherent anti-Stokes Raman spectroscopy (CARS) and stimulated Raman spectroscopy (SRS). Spatial and temporal overlap serves equally well in pump-probe experiments where one laser sweeps across a range of wavelengths. For temporally sensitive pump-probe experiments, the SPL function generator controls dithering of the delays so that only each alternate pulse in the pulse train is synchronized, yet average output power remains constant.

As a fiber-based laser system, the SPL offers a more robust and reliable solution than current conventional lasers for generating two pulses at different wavelengths while remaining synchronized. Because the fiber guides the light, spatial overlap is automatically achieved and maintained without any alignment. Synchronization of the pulses is electronically controlled through common advanced high-speed function generator circuitry that drives both lasers.

User control of the laser system is accomplished via a graphical user interface running on a PC. All parameters are accessible through the interface with no manual intervention required (see Fig. 2).The SPL thus offers a versatile platform capable of delivering a pulse stream from each of the integrated lasers at pulsewidths as low as 10 ps and repetition rates up to 200 MHz while keeping them synchronized. That, along with power levels that can also be configured, provides the elements necessary for applications such as nonlinear spectroscopy.

Programmable picosecond laser

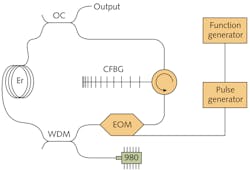

The component at the heart of the SPL systems is the programmable fiber laser (PL), which serves as the tuning engine and offers a wide wavelength tuning range within a series of optical bands. The PL gain medium can be an erbium-doped fiber, an Yb-doped fiber, or a semiconductor optical amplifier. When a doped fiber is deployed as the gain medium, a WDM couples the energy of a 980 nm laser diode to provide core pumping. An optical coupler extracts a portion of the amplified light and delivers it to the output or the next stage (see Fig. 3). The percentage of light extracted through the coupler—which could range from 1% to 50%—depends on the gain medium, the tuning range, and the tuning speed required.The PL is dispersion tuned. A chirped fiber Bragg grating (CFBG) serves as the dispersive element and is addressed by a circulator. Timing of the pulses to the EOM then determines which wavelength will see amplification by coordinating activation of the EOM with the arrival of the desired wavelength's pulse wavefront. In fact, the signaling applied to the EOM controls four parameters: wavelength, wavelength sweep, repetition rate (especially when considering harmonic modelocking), and optical pulsewidth. The EOM is driven by a function generator/pulse generator combination.

In some configurations, there may be limits to the product of bandwidth * delay from some CFBGs, in which case several such gratings may be required to cover the desired wavelength band.

Operated on its own, the PL can output more than 10 million different optical frequencies per second with very high accuracy, stability, and reproducibility. Since the PL is a dispersion-tuned actively modelocked laser, wavelengths may be selected in any arbitrary order, enabling wavelength sweeps in either sequential or arbitrary wavelength sequences. Wavelengths can be selected from the entire range or a partial range. As an example, more than 1000 different wavelengths can be selected from a 10 nm band or 500 wavelengths from an 80 nm band. The steps between adjacent wavelengths may be arbitrary or may be defined through the user interface in any arbitrary order. Sweeps may also be executed in equal steps in wavelength or in optical frequency (k-space or wavenumber). This gives a clear advantage for experiments requiring direct Fourier transformation of the data, providing for faster post-processing.

MOPA

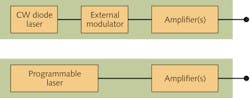

The master oscillator power amplifier is the second integral component of the fiber-based SPL system. The MOPA provides short, high-frequency picosecond pulses that remain synchronized with the pulses from the PL. Because both the PL and the MOPA are under the control of a common function generator, their operations can be synchronized with extreme precision even while the PL is changing wavelengths.

The MOPA can have two possible configurations (see Fig. 4). The first is the classic architecture that utilized a continuous-wave (CW) diode laser, externally modulated at the desired frequency, and then amplified to achieve the desired power level. The second configuration utilizes a simplified version of the programmable laser that can be tuned to a desired wavelength and then amplified as required. Although the MOPA wavelength remains fixed during the PL sweep cycle, this second configuration allows for a certain amount of flexibility in the selection of the MOPA wavelength.As in the case of the PL, the MOPA can achieve pulses as short as 20 ps at repetition rates as high as 200 MHz. In a synchronized mode of operation, the PL and MOPA generate more than 100,000 different optical wavelengths per second while sweeping and maintaining the synchronization of the output pulse streams to less than 2 ps of jitter.

We expect this laser will provide a much-needed wavelength-swept source for nonlinear coherent Raman spectroscopy in tissue for medical diagnosis. In addition, the two lasers may be operated simultaneously or individually, extending the potential of the system. By utilizing the PL on its own, the same system can extend to serve as a fast swept-source laser for applications requiring rapid arbitrary wavelength tuning, such as optical coherence tomography (OCT). Similarly, when set to the desired power level, the MOPA may be used for micromachining, etching, and ablation.

Joseph Salhany is VP, R&D and product management, and Bryan Burgoyne is senior laser scientist at Genia Photonics Inc., 1111 Lapierre St., Lasalle, QC, H8N 2J4, Canada; e-mail [email protected]; www.geniaphotonics.com.