BIOPHOTONICS: Not just for cutting, lasers bond tissues, heal wounds

Researchers at Tel Aviv University (Tel Aviv, Israel) are taking yet another space-age Star Trek gadget from fiction to fact. Besides the modern cell phone "communicator" and demonstration of the "laser scalpel," the Star Trek "dermal regenerator" is now a reality using lasers to both close and heal tissue wounds.

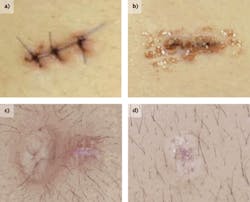

In a recent clinical trial of 10 patients who underwent laparascopic cholecystectomy (surgical removal of the gallbladder), traditional sutures were applied at the end of the procedure to two of four abdominal incisions that had been made in each of the patients. The remaining two incisions were laser-soldered using human albumin (a protein in human blood) solder. Analysis of the wounds by the researchers over a three-month period showed that the 20 laser soldered wounds healed better with less scarring than the sutured wounds (see figure).

Advantages of laser-soldered tissue are its water-tight seal, resistance to infection, faster healing, and minimized scarring compared to sutures (which are subject to foreign-body rejection and cross-hatched scars). The method even improves on chemical glues, which are often toxic and cannot be used internally.

Temperature control is key

Laser soldering is based on applying a biological solder to the approximated edges of a cut and heating the solder (and the underlying tissues) with a laser. While many researchers are focused on controlling such laser parameters as wavelength, fluence, pulse duration, repetition rate, and spot size, the Tel Aviv University researchers found that close control and monitoring of the temperature within the tissue was crucial to successful laser bonding. Because each tissue and each solder absorbs radiation differently depending on tissue type and hydration, for example, it is not enough to apply a fixed set of laser parameters to different wounds.

To solve this dilemma, the researchers developed a temperature-controlled laser bonding system that delivers carbon dioxide laser energy to a spot on a cut via a special polycrystalline silver-halide IR fiber. A second fiber collects IR radiation emitted by the heated spot that can then be used to determine temperature at the tissue site and control the laser power in a feedback loop with an accuracy of ±3°C. Tests found the optimal temperature was 60° to 65°C for a variety of tissue types, with a 10 to 12 s duration for each soldered spot, with multiple spots comprising a tissue-soldered seam.

Even though initial results for the system were promising, several issues were corrected in a second-generation soldering system developed by the researchers: First, a 3D computer simulation was written to take into account the Gaussian heating from the laser spot to ensure that temperatures were nominal to cause bonding without collateral tissue damage; second, the temperature distribution within and thickness of the albumin solder were carefully optimized; and third, the location and angular positioning of the IR fiber tips were optimized such that height sensitivity of the delivered radiation was minimized.

Worldwide research

Research on laser tissue bonding and healing is not just taking place at Tel Aviv University. Researchers at The City College of New York (New York, NY) are also experimenting with laser tissue welding on guinea pig skin and porcine aorta tissue.1, 2 And researchers at the Instituto di Fisica Applicata Nello Carrara (Florence, Italy) are spectroscopically characterizing the effectiveness of albumin/porous silica/gold nanorods as laser tissue-bonding materials and studying the effects of laser-diode welding of corneal tissue.3, 4

"We have already used the laser-soldering system for bonding of incisions in many types of tissues in live animal models, including bladders and intestines. Since our system is based on IR fibers, we were also able to use it for endoscopic soldering of cuts in the kidneys of large farm pigs," said Abraham Katzir, head of the Applied Physics Group at Tel Aviv University. "We are concentrating now on laser soldering of incisions in the cornea and in the skin, trying to obtain permission to carry out clinical trials. Laser soldering is going to replace standard bonding methods and it is expected to revolutionize surgery."

REFERENCES

- A. Alimova et al., "Healing and evaluating guinea pig skin incision after surgical suture and laser tissue welding using in vivo Raman spectroscopy," Photonics West 2010, paper 7561-40 (Jan. 25, 2010).

- C.-H. Liu et al., "Changes of collagen, elastin, and tryptophan fluorescence in laser welded porcine aorta tissues," Photonics West 2010, paper 7561-41 (Jan. 25, 2010).

- F. Ratto et al., "Spectroscopic and microscopic characterization of albumin/porous silica/gold nanorods," Photonics West 2010, poster session 7577-42 (Jan. 25, 2010).

- F. Rossi et al., "Long term observation of low power diode laser welding after penetrating keratoplasty in human patients," Photonics West 2010, poster session 7550-77 (Jan. 25, 2010).

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.