An organic optically pumped solid-state laser called a vertical external-cavity surface-emitting organic laser (VECSOL), developed by scientists at the Laboratoire de Physique des Lasers at Université Paris (Villetaneuse, France), produces a high-quality beam at a conversion efficiency of 43%, and also is tunable.1 With further development, the dye laser could be of practical use for sensing or communications over plastic optical fibers.

The gain medium is an organic polymethyl methacrylate (PMMA) film doped with Rhodamine 640 to 1% by weight and spun-cast onto a flat mirror to a thickness of a few microns. The flat mirror has a reflectivity greater than 99.5% for wavelengths between 600 and 660 nm; a concave (200 mm radius of curvature) output-coupler mirror with a reflectivity of 98% between 600 and 880 mm is placed 4 mm away from the flat mirror to complete the laser cavity.

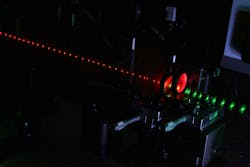

The two mirrors are transparent to light at 532 nm, which is the pump wavelength. The PMMA film, however, absorbs 80% of the pump light in a single pass when cast at a 17 µm thickness. The VECSOL is pumped by a frequency-doubled Nd:YAG laser beam emitting either a "long pulse" of 7 ns duration, or a "short pulse" of 0.5 ns duration, both with a 10 Hz repetition rate and a pump-beam diameter of 140 μm (see figure).

Serendipitous tunability

For long-pulse pumping, the VECSOL shows a lasing threshold of 1.8 μJ, a maximum output energy of 6 μJ (870 W peak power), and an optical-to-optical efficiency of 43% (a quantum efficiency of 63%). The emission, which is linearly polarized in the direction of the pump beam and is diffraction-limited (beam quality M2 of 1.0), is centered at a wavelength of about 655 nm but consists of several peaks between 640 and 670 nm spaced by 7.5 μm—which is the free spectral range of the Fabry-Perot etalon formed by the thickness of the PMMA film. As a result of the spin-casting, the PMMA film ended up with a variation in thickness across the mirror; this allows the laser to be tuned over a 20 nm range by laterally translating the mirror.

The researchers also tested PMMA thicknesses of 10, 5.6, and 2.35 μm. They observed the expected variation in peak spacing for the different thicknesses; the spacing for the thinnest film was large enough that the laser produced only a single peak (although the single peak was not tunable because the thinnest coating had a uniform thickness).

Short-pulse pumping produced a threshold of 0.95 μJ, a maximum output energy of 0.7 μJ (2 kW peak power), and a conversion efficiency of 6.3%.

The researchers note that the cavity length for the VECSOL can be increased to 60 mm for long-pulse pumping and 10 mm for short-pulse pumping, allowing experimenters to insert intracavity optics.

"This laser could be interesting for applications which require a cheap, compact, easy-to-handle tunable source in the visible range," says Sebastien Chénais, one of the researchers. "The key difference between the VECSOL and distributed-feedback organic lasers or organic microcavity lasers is the perfect diffraction-limited beam quality and the very high conversion efficiencies that are attainable. The beam can for instance be coupled easily to a polymer optical fiber, whose transmission is maximum around 650 nm, which corresponds to the wavelength range of our laser. This could then be used for short-haul data communications. Another potential application is spectroscopy of organic molecules, including biological systems, or chemical sensing. It could then replace expensive and bulky optical parametric oscillators or liquid dye lasers in those fields where modest energies in a pulsed mode are required."

Chénais believes that, provided some improvements are made to the VECSOL (for example, adding well-controlled wavelength tunability), it could be of interest to industry. The cost of the whole system is now approximately the cost of the pump laser, he notes; with a cheaper pump source such as a laser diode, the device can become cost-effective.

Easily recoated

"The ultimate goal would be the achievement of electrical pumping with an organic semiconductor as the gain medium, but this perspective is today still a big challenge for the community and cannot be regarded as realistic within a short-term period," says Chénais. "The limitation brought about by the inherent low photostability of organic dyes is highly reduced compared to solid-state dye lasers using bulk dye-doped polymer blocks (or compared to other more complex structures that require a patterning of the active medium), since here it takes only a few minutes to rinse the mirror and coat it with a fresh active layer."

REFERENCE

- H. Rabbani-Haghhighi et al., Opt. Lett. 35, 12, p. 1968 (2010).

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.