ANDREW KULAWIEC

The advantages of using aspheres in optical systems are well known and proven. Aspheres are used extensively in a variety of applications such as infrared imaging for defense applications, where advances in single-point diamond turning have enabled their manufacture. They are also used in high-volume applications such as cell phones and digital cameras, where molding technologies have advanced enough to produce optics of sufficient quality.

However, the widespread use of aspheres in higher-precision imaging systems has lagged, in part due to the lack of flexible, full-aperture metrology (an example of the "you can't make it if you can't measure it" saying often cited by advanced manufacturers). In particular, the drive toward tighter overall figure-error tolerances (specifications) in addition to the growing awareness of the impact of mid-spatial frequencies has highlighted the need for high-resolution, full-aperture metrology.1 Furthermore, accurate full-aperture metrology is often required as input to magnetorheological finishing (MRF) and other deterministic finishing processes.

Pre-existing measurement approaches

Aspheric metrology has traditionally been performed using either stylus profilometry or null interferometry. Both classes of techniques have advantages and disadvantages. Profilometry is very flexible and can be cost-effective, but its accuracy is limited and it does not provide high-resolution, full-aperture results. Null interferometry does provide full surface coverage (depending on the size of your optic relative to the interferometer), but it's not very flexible or cost-effective given the need for a custom setup or null lens for every different asphere.

Recent advances in non-null interferometric techniques such as sub-Nyquist and zonal-synthesis interferometry have provided new alternatives, but both of these techniques are limited in terms of the size of optic and aspheric departure that can be measured.2, 3 Their ability to measure mid-spatial frequencies is also limited by the quality of the imaging optics and the number of camera pixels in the interferometer.

Subaperture-stitching interferometry was developed to extend the capabilities of conventional interferometry, allowing the measurements of larger diameters and numerical apertures (up to full hemispheres) while significantly increasing the lateral resolution and accuracy.4 Stitching was then extended to the measurement of aspheres through the measurement of non-null fringe patterns with magnification and finding the local best-fitting sphere.5 However, this approach is limited to the measurement of mild aspheres (typically less than 200 waves of departure from the best-fit sphere), due to the ever-increasing fringe densities obtained as the asphere becomes steeper. These increased fringe densities are a result of the mismatch between the spherical wavefront from the interferometer and the nonspherical shape of the asphere within the subaperture.

Variable optical null

To maintain all of the benefits of subaperture-stitching interferometry while significantly increasing its aspheric-departure capability, the concept of the variable optical null (VON) has been introduced and developed by QED technologies.6 A VON is an optomechanical device that takes the spherical wavefront generated by a conventional interferometer and adds aberration to it in order to nearly match the local shape of the asphere within a given subaperture. By generating a wavefront that nearly matches the shape of the asphere, the fringe densities are significantly reduced. Note that it is not necessary to generate a perfectly nulled fringe pattern; rather, it is only necessary to produce a fringe pattern that is resolvable by the interferometer over the full subaperture.

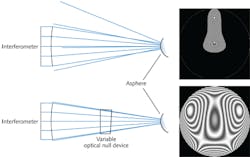

For rotationally symmetric aspheres, the dominant shapes of the asphere within an off-axis subaperture are astigmatism and coma. Therefore, an ideal VON would generate controllable amounts of each aberration since different locations on the asphere will have different amounts of these shapes. It would also consist of relatively simple optics and motions, since it will be necessary to generate a model of the wavefront being created. From basic aberration theory, it is well known that an optical wedge placed in a spherical wavefront introduces both astigmatism and coma, depending on the amount of wedge and the tilt of the wedge in the beam. A device known as a Risley prism pair is ideally suited for this task (see Fig. 1). By independently rotating each prism and tilting the entire device in the beam, different amounts of astigmatism and coma can be generated.

The basic principle can be easily illustrated by tracing rays with and without a VON (see Fig. 2). In both cases, a spherical wavefront is generated by the interferometer. Without the VON, the mismatch between the spherical wavefront and the asphere results in an extremely high-density fringe pattern (shown to the right of the ray-trace diagram). With the VON in place and optimized for wedge and tilt, the fringes are now resolvable over the full subaperture, due to the good match between the aberrated wavefront and the shape of the asphere. The interferometer can easily measure this fringe pattern, and when combined with the model of the wavefront generated by the VON, the precise shape of the aspheric surface (including any figure error) can be determined.Departures up to 1000 waves

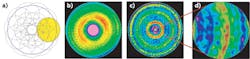

We have developed an instrument based on subaperture-stitching interferometry combined with a VON device.7 The Aspheric Stitching Interferometer (ASI) is a multiaxis motion-control platform incorporating an industry-standard 6 in. Fizeau interferometer and advanced control software and stitching algorithms. The ASI is capable of accurately measuring flats, spheres, and aspheres with diameters greater than 200 mm (up to 300 mm in many cases) and with numerical apertures up to 1.0 (full hemisphere), concave or convex. The incorporation of the VON in the ASI allows for automatic measurement of a wide variety of aspheres with up to 1000 waves of departure from the best-fit sphere.In one example, an asphere to be measured has approximately 60 μm of departure from the best-fit sphere (see Fig. 3). The lattice (pattern of subapertures) used to measure this part is shown in Fig. 3a. Using a 6 in. f/2.2 transmission sphere, approximately 20 subapertures are required to cover the part with sufficient overlap. The full resolution of the interferometer (1000 × 1000 pixels) is obtained within each subaperture. It is therefore possible with stitching to obtain very high-resolution output maps of the surface error, consisting of several thousand pixels in each direction. The example full-aperture map consists of approximately 3 million data points. If low-order Zernike terms are fitted and removed from the measurement, the finer structure of the surface becomes more visible. A magnified section of this data clearly displays the mid-spatial frequency content of the surface, as well as the high-resolution capabilities of the ASI.

REFERENCES

1. D. Aikens et al., "Specification and Control of Mid-Spatial Frequency Wavefront Errors in Optical Systems," OSA/FiO/LS/META/OF&T 2008.

2. J.E. Greivenkamp, Appl. Opt. 26, 24, p. 5245 (Dec. 15, 1987).

3. M.F. Kuechel, "Absolute Measurement of Rotationally Symmetrical Aspheric Surfaces," in Optical Fabrication and Testing 2006 (OSA), OTFuB5.

4. P. Dumas et al., "Extending the range of interferometry through subaperture stitching," Optifab 2003, Tech. Dig. SPIE, Vol. TD02 (2003).

5. P. Murphy et al., "Accurate interferometric measurements of mild aspheres without null correction," Optifab 2007: Technical Digest of SPIE, TD04, TD040N, (2007) 0277-786X/07/$15 doi: 10.1117/12.719484, Proc. SPIE, Vol. TD04 TD040N-1.

6. A. Kulawiec et al., "Subaperture-stitching interferometry of high-departure aspheres by incorporating configurable null optics," Optifab 2009, TD06-44.

7. U.S. and International Patents pending.

ACKNOWLEDGMENT

MRF and ASI are registered trademarks of QED Technologies. VON is a trademark of QED Technologies.