LIGHTING: Tailored emissivity paves way for 400 lm/W incandescent lamps

Just when you thought incandescent light bulbs were dead, researchers at Stanley Electric Corp. (Tsukuba, Japan), Osaka University (Osaka, Japan), Shizuoka University (Shizuoka, Japan), and the National Institute of Advanced Industrial Science and Technology (Tsukuba, Japan) have modified the blackbody radiation of an incandescent bulb, demonstrating the possibility of 95% electric power to visible-light conversion and paving the way for luminous efficiencies beyond 400 lm/W.1, 2

The inherent inefficiency of traditional incandescent lamps (only 2–5% of total input electrical power is converted to visible light, translating to low luminous efficiencies of 15–20 lm/W) has brought about their demise in favor of fluorescent lamps and LEDs. Unlike these modern sources, incandescent lamps require no external regulating equipment, are inexpensive to produce, and work on either alternating or direct current over a wide range of applied voltage values. Despite the failure of previous research to modify the blackbody radiation spectrum of an incandescent bulb (using expensive lithography and deposition techniques), the research team focused on selective-emitter design using tailored and less expensive thin-film coatings to improve efficiency.

High visible and low IR emissivity

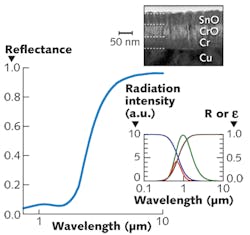

Because visible radiation is typically 10% of the output from an incandescent bulb, with the remaining 90% being infrared (IR) radiation, an emitter should be designed with high visible emissivity and low IR emissivity. Using Kirchhoff's law, modeling shows that a material with high reflectance in the IR wavelength region and low reflectance in the visible region displays a reverse trend in emissivity. By imposing a step-function-like reflectivity onto the surface of the heating material, IR radiation is reduced.

The researchers fabricated such a thin-film structure (emitter) by co-sputtering 50 nm thick chromium metal and 50 nm thick chromium oxide onto a copper substrate. After deposition, a 50 nm thick tin oxide layer was deposited onto the chromium oxide layer to act as an antireflection coating. Spectrophotometer measurements from 300 to 1500 nm and Fourier-transform IR spectrometer measurements from 1500 nm to 20 μm showed that the film reduced IR radiation at wavelengths shorter than 5.5 μm (see figure).

The shift to visible emission (shorter wavelengths) occurs at temperatures between 580 and 870 K. Further mathematical modeling of the thin-film structure as a function of temperature shows that an emitter constructed with a reflectance cutoff wavelength in the visible region would have no IR component in its radiation spectrum and the conversion efficiency would exceed 90% at 2800 K. Because this efficiency is high, the bulb could be operated at lower voltages (with lower filament heating temperature), extending the lifetime of the emitter and the overall source.

Professor Makoto Tomita in the Department of Physics at Shizuoka University says, "We can make efficient monochromatic light sources such as blue, green, and red lamps by designing the reflectivity of a selective emitter. Almost 200 years have passed since the creation of the first incandescent light; however, there is ample scope for new discoveries and new applications in incandescence."

REFERENCES

1. T. Matsumoto and M. Tomito, Opt. Exp. 18, 102, A192–A200 (Jun. 21, 2010).

2. T. Matsumoto et al., The Science and Technol. of Light Sources 12th Intl. Symp., paper CP091, Eindhoven, the Netherlands (Jul. 13, 2010).

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.