TUNABLE SEMICONDUCTOR SOURCES: Scientific applications benefit from external-cavity diode lasers

MALCOLM MINTY

Most researchers and engineers would not associate descriptions like compact, maintenance-free, and power-efficient with the lasers typically found in a scientific laboratory. Commercial diode lasers offer these advantages but, unless they are modified, diode lasers generally can't meet the demanding specifications required for scientific use. External-cavity diode lasers are systems that take diode laser performance to a level that can meet research specifications. They also enable researchers to focus more time on actual research and less on keeping the laser operating at specifications. In addition to a general trend to turnkey systems as replacement lasers, more applications such as quantum computing, atomic spectroscopy, and phase-shift interferometry are being enabled by scientific-grade diode laser systems that embody the results from investments made in telecom and other industries.

External-cavity diode lasers (ECDLs) are based on off-the-shelf laser diodes, which are available in a wide range of wavelengths. These standard devices, used in high-volume applications like telecommunications and consumer electronics, typically have a short cavity and are very sensitive to temperature. Their spectral output is generally a few nanometers wide, which is too broad for most scientific applications. In order to probe, measure, and interact with samples in an application such as Raman spectroscopy or atom cooling (see "Lasers enable breakthroughs in atomic physics" on page 67), a stable, narrow-linewidth light source is needed and the laser diode must be modified.

Precise mechanical control

An external cavity allows a specific wavelength with a narrow linewidth to be selected from the broad gain region of a laser diode's output. The wavelength can be precisely tuned or scanned by mechanically adjusting the cavity. External-cavity diode lasers are not new and several companies developed commercial products in the 1990s. Interest peaked in the heady days of the telecom bubble. Outside of some test and measurement applications where wide tuning is needed, most tunable telecom lasers are now based on distributed feedback (DFB) technology where the diodes are current-tuned over a narrow range. However, DFB lasers are only available at limited wavelengths, cannot be widely tuned, and typically have megahertz linewidths.

External-cavity devices have advanced steadily in the years since the telecom bubble. Atomic spectroscopy requires narrow linewidths to tune over precise transitions. Keeping the cavity steady while maintaining the ability to move a grating or mirror accurately and repeatedly with submicron precision is a major challenge. Vibration, acoustic perturbations, or thermal drift must also be addressed because they can result in a broadening of the laser linewidth, mode hops, or shifts in the lasing wavelength. Techniques like passively damped precision mechanics and electronic feedback loops–or a combination of both–have made ECDLs extremely reliable in demanding applications.

Precision movement of the grating or mirror can be achieved using a variety of actuators. Piezos, DC stepper motors, and voice-coil motors are all used by New Focus, depending on the required application. Faster scanning over a wide range requires a lightweight and flexible, fast-moving tuning arm. However, this may result in reduced mechanical stability and can lead to a broad linewidth. For home-built systems, a simple but rugged micrometer is adequate for tuning slowly to the required precise wavelength. At the other extreme, for fast optical coherence tomography applications, microelectromechnical systems that operate at many kilohertz are used where only a limited coherence length is required; therefore, a broader linewidth is acceptable.

New Focus is one company that has added magnetic damping to the tuning arm of its Vortex II lasers to further reduce mechanical resonance. Other companies have developed ultrastable mounts, which are of particular importance when multiple resonant cavities are in series-for-complex systems.

Development milestones that showcased the technology outside of telecom and proved that such lasers could be ruggedized include space qualification by New Focus of a 780 nm laser for atomic spectroscopy on the International Space Station and Toptica's (Munich, Germany) demonstration of fourth harmonic UV output based on multiple resonant cavities.1

Cavity design choices

There are two common cavity choices for ECDLs and both require a high degree of precision. The simplest is the Littrow cavity, which uses a grating to direct light back into the external cavity. This configuration is mechanically straightforward and uses the first order reflection, thereby achieving a high level of power efficiency. Simple Littrow cavity lasers are commonly home-built in the lab, but they suffer from limited mode-hop-free tuning range because the cavity length varies as the grating is tuned. The beam direction also moves as the grating angle is varied. Commercial systems overcome some of these difficulties by adjusting the laser diode current to maximize the tuning range and by mechanically compensating for the beam steering.

The alternative cavity design is the Littman Metcalf cavity, which fixes the grating in place and tunes a mirror to adjust the wavelength. Its primary disadvantage is the loss of power due to the second order reflection being used and that the laser diode requires a more precise antireflection (AR) coating. Its principal advantages, and the reason New Focus has used this design for 15 years, is the much wider mode-hop-free tuning range and lack of beam walk.

Regardless of the choice of cavity design, the diode selection is critical. Commercial laser diodes are manufactured in the millions by diode fabs located, for the most part, in Japan and other parts of Asia. Unfortunately, asking major electronics companies to make a handful of devices at a special wavelength that can be used in an ECDL for a specific scientific application does not normally result in much interest. Some smaller fabs may be willing to do custom diode runs, but another solution is to take standard diodes and apply an additional AR coating to adjust the output. Having this AR coating capability in-house allows New Focus to make custom systems based around commercial diodes in low volumes for scientists and industry.

Increasing power, maintaining linewidth

As diode technology has advanced, available output power has increased from a few to hundreds of milliwatts. Demand for higher power has been driven especially by the cold atoms research community, which needs more power to interact with larger amounts of atoms when studying transitions.

Increasing output power brings another challenge–the need for a low-noise current supply. Current ripple introduces minor variances to the diode itself, which can broaden the linewidth of the laser. Keeping the linewidth below 1 MHz becomes a challenge, so to achieve high power with a narrow linewidth a two-stage system master oscillator power amplifier is used. A low-power, narrow-linewidth master oscillator in an external cavity seeds a power amplifier diode chip. This second stage does not lase by itself but has a tapered structure that amplifies the power without significant changes to the linewidth.

Although only available for a limited wavelength range, these tapered amplifiers enable output power of 1 W or more to be produced. The result is that these two-stage ECDLs have largely replaced legacy gas lasers, tunable dye lasers, and some solid-state crystal-based devices. The latest amplifiers incorporate power monitoring and closed-loop current control electronics. This new level of reliability and ruggedness enables these systems to work in applications outside the lab such as atmospheric monitoring and lidar. Furthermore, this higher power now enables efficient nonlinear processes such as frequency doubling, which has opened up new applications like quantum computing and ion trapping that were not previously possible.

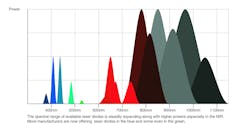

Scientific diode lasers systems have benefitted from 20 years of billion-dollar investments made in consumer electronics. Telecom and optical storage applications gave researchers access to cheaper diodes at an expanding range of powers and wavelengths (see figure). The next round of investment seems likely to originate from the demand for red/green /blue (RGB) projectors. Green laser diodes and reliable higher-power blue diodes will see ECDLs gain further acceptance as they open up new applications and make existing techniques simpler. They will be able to challenge frequency-doubled solid-state lasers in efficiency and offer a much wider choice of wavelengths for scientists working in spectroscopy and metrology applications.

REFERENCES

1. T. Schmitt, T.A. Puppe, A. Nendel, F. Lison, W.G. Kaenders, M. Le Flohic, CLEO/QELS 2009 (June 2009).

Malcolm Minty is a product marketing manager at New Focus, a brand of Newport Corp., 1791 Deere Ave. Irvine, CA 92606; e-mail: [email protected]; www.newport.com.

Lasers enable breakthroughs in atomic physics

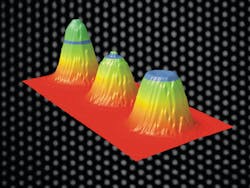

Realizing a new state of matter. Building a quantum computer. Creating the coldest place in the universe. Detecting infinitesimal fluctuations in gravitational fields. Measuring time to a part in 1018. These are just some of the advances in atomic physics made possible in recent years with the development of high-precision lasers.A fifth state of matter, the Bose-Einstein condensate (BEC) was first theorized by its namesakes in 1925 but was not realized until 1996 by Cornell, Wieman, and Ketterle, who received the 2001 Nobel Prize in Physics for this work. Laser cooling (for which another Nobel Prize in Physics was awarded to Chu, Cohen-Tannoudji, and Phillips in 1997) in the form of magneto-optical traps (MOT) enabled the cooling of atoms to the nano-Kelvin (nK) regime, thereby creating a condensate of atoms that act in concert to exhibit quantum effects observable on a macroscopic level. These breakthroughs have resulted in a proliferation of research into a variety of fields including atom interferometers, precision atomic clocks, few-body physics, quantum optics, and quantum information. The recent International Conference on Atomic Physics (ICAP) in Cairns, Australia in July 2010 highlighted how far this field has developed.

Tunable external-cavity diode lasers are now a fundamental part of the atomic physics experimental apparatus. They are used for laser cooling in MOTs for BECs, degenerate Fermi gases, and ion traps. Recent advances in these lasers–narrower linewidths, ability to frequency-lock to fine precision, higher power levels, and new wavelengths–have been critical to their widespread use in atomic physics applications. As the field expands to increasingly complex experiments and new atomic and ionic species, tunable external-cavity diode lasers will continue to advance to meet the demanding needs of the exciting field of atomic physics.

REFERENCE

Nature, Vol. 460, No. 20, doi:10.1038/nature08244 (August 2009).