Metamaterial is electrically switched from reflector to absorber

An electrically controllable metamaterial developed by a group at Nanjing University (China) can be switched to independently reflect or absorb light for either or both TE and TM polarizations; the effect is valid for incidence angles ranging from 0° to 50°. Like many metamaterial prototypes, this structure was fabricated for use at microwave wavelengths, where the unit cell size is on the order of 10 mm and thus easy to make. Also like many of the prototypes, the researchers say the concept can potentially be applied at optical frequencies, where the unit size would shrink to much less than a micron.

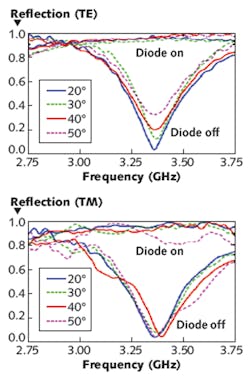

The metamaterial actually contains two independent layers, one to switch each polarization. Each layer contains an array of electric-LC (inductor-capacitor) resonators on top of a dielectric, with a metallic film underneath. The wave impedance of the metamaterial matches that of free space; a resonance causes absorption of the microwaves. A forward-bias voltage on the diodes created in the structure causes the resonance to be destroyed, boosting reflection. The reflection is continuously tunable from zero to maximum. The figures show reflection of the metamaterial for the two orthogonal polarizations (TE and TM) at various incidence angles with the diodes either on (applied voltage) or off (no voltage). Contact Yijun Feng at [email protected].