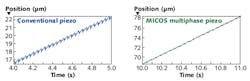

Multiphase piezo nanopositioner dramatically reduces stick-slip aberrations

Engineers at Micos USA (Irvine, CA) have developed a multiphase piezo motion technology that significantly reduces the conventional "stick-slip" operation of nanopositioning applications. Conventional piezo motors often use stick-slip inertial motion in which the piezo element is connected to an oscillating friction element that moves the sliding friction element forward when the piezo extends due to an applied voltage. When the piezo is fully extended (usually below 1 μm), a fast voltage transition is applied that quickly contracts the piezo, resulting in a fast backward motion of the oscillating friction element during every slip phase, which occurs approximately every 500 nm. The sliding friction element (moving part of the actuator) follows the backward movement to some degree during the slip phase, which results in poor velocity regulation, induced vibration into the system, and lost motion.

The multiphase piezomotor from Micos uses at least two piezos and friction elements that move in unison but slip at different times, minimizing the retract motion induced by the slip forces and significantly reducing or even eliminating altogether the backward motion during the slip phase. For example, one device has 12 mm travel with better than 1 nm motor resolution, 5 nm linear-encoder resolution, and 1 kg horizontal-load capability. Contact Manfred Schneider at [email protected].