METAMATERIALS: Three-layer metamaterial lens focuses terahertz radiation

An optical metamaterial is made up of unit cells somewhat less than a wavelength in size. This means that the unit cells, which may contain intricate metal structures as well as dielectrics, directly scale in dimension with the wavelength the metamaterial is designed to handle. As a result, many theoretical metamaterial structures are first tested at microwave wavelengths because the cell size is an easy-to-fabricate 10 mm or so; in contrast, metamaterials for the visible region may have unit cells on the order of 200 nm in size. Visible metamaterials also tend to be very highly absorptive.

However, the "in-between" terahertz spectral region, which is now being exploited for testing of chemical substances, industrial quality control, and security and other imaging systems, appears to be a prime target for metamaterial technology. The unit-cell size for a terahertz metamaterial is tens of microns in size—easily fabricated using photolithography—and the materials are not overly absorptive. And metamaterial optics are a boon for the terahertz region, which is lacking in conventional optical materials suitable for use in imaging components such as focusing lenses.

Gradient-index (GRIN) lenses made of spectrally broadband metamaterials have been developed by researchers at the University of Kaiserslautern (Kaiserslautern, Germany) and the Fraunhofer Institute for Physical Measurement Techniques (Freiburg, Germany); in particular, the group has created a three-layer GRIN lens that focuses more strongly than a single-layer GRIN lens in the 1.2 to 1.5 THz region.

Annular-slit unit cell

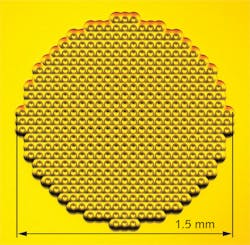

For an experimental comparison, two metamaterial GRIN lenses were fabricated, both using unit cells with 60 × 60 μm lateral dimensions and 40 μm in the axial direction (see figure). The first lens consisted of a single layer of cells, with each cell made up of a dielectric sandwich containing a film of copper at its center; the copper layer in each cell incorporated an annular slit with a constant slit width of 3 μm, but with the slit diameter ranging between 18 and 23 μm as a function of the cell's radius from the optical axis of the lens, creating a parabolic refractive-index profile that varied from 0.08 to 1.65 at a center frequency of 1.3 THz.

The second lens was similar except that it contained three layers instead of one, resulting in a lens with higher focusing power. Both lenses were designed so that they did not operate in the Bragg regime for the frequencies of interest (meaning that it did not operate as a conventional diffractive lens, which would result in losses into undesired orders).

To produce terahertz radiation, 15 fs pulses from an ultrafast laser were focused between the poles of a photoconductive switch, and the resulting polarized radiation collected by two off-axis parabolic mirrors and focused to a spot 1.5 mm in size. For test, the GRIN lenses were carefully aligned with the optical axis to eliminate any skewed focusing.

The GRIN-lens focal spot was imaged at a spatial resolution of 60 μm by directing it onto a slab of gallium phosphide (GaP) and measuring the resulting electro-optic effect by scanning the GaP with an optical probe. Results showed that the single-layer GRIN lens focused to a spot size of 320 μm, or 1.45 times the wavelength of the terahertz radiation. The three-layer lens, however, was able to focus down to a 220 μm spot size, or only 0.96 of the wavelength. Throughout the 1.2 to 1.5 THz range, the spot sizes varied from 1.45 to 1.75 times the wavelength for the single-layer lens and 0.94 to 1.05 times the wavelength for the three-layer version.

REFERENCE

1. J. Neu et al., Opt. Exp., 18, 26, 27748 (2010).

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.