A research group at Kookmin University (Seoul, Korea) and PSI Co. (Kyungki-Do, Korea) is touting the high efficiency and other properties of green LEDs that consist of a blue LED, a phosphor that converts blue to green, and a long-pass dichroic filter (LPDF) that filters out the remaining blue light. This type of phosphor-coated LED (pc-LED) compares favorably with LEDs that combine a blue LED and green phosphor but without an LPDF, because such LEDs require a thicker layer of phosphor to block out all the blue light, reducing total green light output in the process.

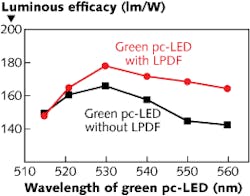

Standard gallium-nitride-based green LEDs suffer from both low electroluminescence efficiency and considerable efficiency droop (lower efficiency at higher currents). Thus, many worldwide are attempting to create green LEDs that operate via a different approach. The Korean group’s version consists of a 445-nm-emitting blue LED, a phosphor with a peak wavelength that can range from 515 to 560 nm depending on composition, and a multilayer LPDF. Measured luminous efficacies range from 143 to 173 lm/W depending on the phosphor composition, with the external quantum efficiencies of the green LEDs falling in the range of 0.31 to 0.35. With a better blue LED and better optics and packaging, the researchers hope for luminous efficacies of 286 to 315 lm/W. Contact Young Rag Do at [email protected].

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.