PHOTOVOLTAICS: Thermophotovoltaic device design has double the efficiency

While photovoltaic (PV) cells that extract energy from sunlight are getting much attention, another type of PV device has great promise too. Semiconductor thermophotovoltaic (TPV) devices are similar to solar cells but have a smaller bandgap, allowing them to extract energy from heat sources such as waste heat from power plants, automobiles, and even thermal solar power sources. Increasing the efficiency of TPV devices could change them from a rarely used curiosity to an important tool for increasing the effectiveness of energy extraction worldwide.

Jian Yin and Roberto Paiella of Boston University (BU; Boston, MA) are studying the use of intersubband transitions in quantum-cascade (QC) semiconductor structures to capture energy from photons over a broadband range in the IR.1 This sort of structure, which has multiple junctions each with different bandgap energies, is already used in some IR photodetectors in a simpler form in which the cascade stages are identical.

The two BU researchers have completed a performance analysis of QC TPV structures to determine their ultimate efficiency and have found that their use could double the output electrical power of present-day TPV devices.

Four-stage device

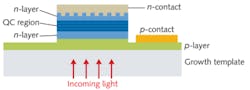

The structure they selected is based on an indium gallium arsenide (In0.67Ga0.33As) p-n junction with a 0.6 eV bandgap integrated with a series of differing QC stages based on In0.83Ga0.17As/AlAs0.65Sb0.35 quantum wells. The proportions of elements in the QC stages is close to that in the p-n junction, eliminating net strain accumulation and accompanying defect formation. Because the device naturally absorbs only TM-polarized light, an embedded 2D reflection grating scatters the TE-polarized photons so that they are also absorbed.

The model assumed a device with four different QC structures subjected to blackbody radiation with a temperature of 1300 K. The high-absorption band of the combined four structures reached from just over 0.2 eV to just under 0.6 eV, or a good portion of the 1300 K blackbody-radiation spectrum.

The electrical current density of all four stages was the same by design—about 4 A/cm2. The model showed the TPV device had a short-circuit current density, open-circuit voltage, and fill factor of 4.9 A/cm2, 0.92 V, and 63%, respectively. Especially important, its maximum output electrical power density was just over 2.8 W/cm2. The researchers also used their model to calculate the energy conversion of the best existing TPV device at 1300 K—a photodiode that has experimentally produced an energy conversion of about 0.8 W/cm2. The model, which was of the detector's p-n junction by itself, gave an efficiency of 1.4 W/cm2, or half that of the QC design.

REFERENCE

1. J. Yin and R. Paiella, Appl. Phys. Lett., 98, 041103 (2011).

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.