SOFTWARE & COMPUTING: Software drives development of a 'perfect' interference coating

JENNIFER D.T. KRUSCHWITZ

When referring to optical coating design software a discussion may turn to some of the powerful numerical methods utilized within an individual software package.1 Many users will claim that their loyalty lies with a software package because it incorporates a complex synthesis or refinement method. Invariably when probed further that same individual may also claim that sometimes designs are created that are just too complex for their manufacturing systems to be able to produce. How does one know when to stop the synthesis process? Does a merit function close to absolute zero buy the designer a design that will fulfill their customer’s needs and that can be manufactured repeatably on the production floor?

Software developers have focused their efforts on making their software more powerful on a refinement and synthesis level as well as incorporating a user-friendly interface and the ability to import spectral performance data or print out run-sheets. Fairly recently development has turned to creating an environment that will assist users in evaluating the manufacturability of their complex designs. Repeatability in manufacture is the number one priority for many coating houses, so demand has increased for more efficient evaluation tools for conceptual designs.

Characterization methods

Understanding design performance requires effective characterization of the optical properties of the materials to be used in the design. It is unproductive to use materials without dispersive information other than to educate novices in basic design theory. Solid understanding of the optical characteristics of the design layers will lead to real-world performance within the confines of the software. Most software packages are equipped with dispersion models that can evaluate dielectric materials with small amounts of absorption. As coating houses start to use more nontraditional materials in their designs such as electrochromics, transparent conductors, and metallic binding layers, or even optimize their processes to produce materials with low water absorption or extended UV transmission, models will be required that can characterize sharp index and absorption transitions.

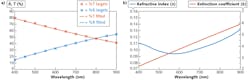

Two new dispersion models referred to as n(λ) and k(λ) are able to characterize materials that exhibit sharp transitions in their refractive index and extinction coefficients such as those exhibited by very thin metallic layers (see Fig. 1).2 These models can characterize UV absorption edges, water absorption in the 3–5 µm region, and Restrahlen bands in the 8–14 µm region for traditional dielectric materials. Use of the n(λ) and k(λ) models is not limited to single films in air, they can also be used in a post-process analysis tool for multilayer films. Binder layers of materials such as nickel-chromium (NiCr) will have completely different optical properties if they are embedded within a multilayer than as a single thick NiCr layer in air. If the designer has sufficient information about the optical and thickness properties of surrounding layers then it is possible to reverse engineer the optical properties of a thin layer of NiCr from the total reflected and transmitted spectral performance of the entire system of layers.

Reducing complexity

Many manufacturing processes have limitations on the overall physical thickness of a multilayer design, total layer count, or even the minimum thickness of any single layer. Synthesis algorithms such as the Needle method or Gradual Evolution leverage adding thin layers or increasing total optical thickness to find an absolute minimum of the merit function. Once designers have reached what appears to be the lowest achievable merit function they may decide to remove layers, increase thin layer thicknesses, or reduce obvious thick layers manually and then re-refine to achieve a design that fits the parameters of their equipment. A design synthesis tool referred to as Design Cleaner can be used automatically after a suitable merit function has been achieved through traditional synthesis methods to reduce the layer count and overall physical thickness of a design while confining the merit function increase.3 This way the software will create the manufacturable design automatically without sacrificing performance.

Identifying optical monitoring strategies

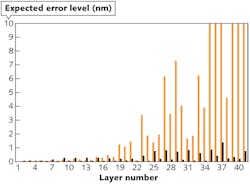

Monochromatic optical monitors are used within numerous coating systems, and traditionally “turning point” optical monitoring has been a predominant method for optical coating designs with a multiple integer of a quarterwave optical thickness for each layer.4 When a single chip is used for the designs with non-quarterwave optical thicknesses, the monitoring technique based on the choice of the most sensitive wavelength has often been applied. In this case, small thickness errors in starting layers of a design can produce a strong cumulative effect of thickness error, leading to failed spectral performance of the design.

This fact led to development of new optical monitoring strategies that will diminish overall thickness errors and not allow them to propagate and intensify over the course of the coating run (see Fig. 2).Manufacturing error and yields

There is a need within the coating manufacturing community to stay competitive by developing designs that meet more complex optical system criteria—determination of yield is also important in predicting a competitive selling price. A virtual coating chamber has been created specifically to perform numerous test trials of complex designs within the software, alleviating the need for actual test runs, and increasing the ability of the designer to determine yields based on performance against customer requirements.5 In either the Broadband or Monochromatic Monitoring Simulation users can try out several designs in virtual equipment where they enter material deposition rates, monitor sensitivities, and so forth then run hundreds to thousands of computational test runs. The software can help the designer evaluate repeatability and determine yields for not only spectral performance but also reflected or transmitted color of a design.

For more than 20 years, the goals of design software development have been to create synthesis tools that could solve the most intricate design problems. More recently the focus has turned to leveraging computational strength to assist designers in characterizing materials and transforming complex designs to fit any manufacturing process as well as generating potential yield information.

REFERENCES

1. J.A. Dobrowolski, Opt. & Photon. News, 8, 6, 24–32 (1997).

2. T. Amotchkina et al., Appl. Opt., 50, 1453–1464 (2011).

3. A. Tikhonravov, M. Trubetskov, and I. Kashahara, IEICE Trans. Electron., E91-C, 1622–1629 (2008).

4. H.A. Macleod, Optica Acta, 19, 1–28 (1972).

5. A. Tikhonravov, M. Trubetskov, T. Amotchkina, and V. Pervak, Appl. Opt., 50, C141–C147 (2011).

Jennifer D.T. Kruschwitz is principal, JK Consulting, Rochester, NY, and adjunct assistant professor, University of Rochester & University of Arizona; e-mail: [email protected].