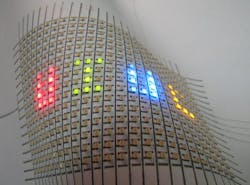

Nanoparticle conductive ink for flexible photonics is easy to apply

Researchers at the University of Illinois have created a silver-nanoparticle-based ink that can be used in a rollerball pen to draw electrical connections for flexible LED displays and other devices (rollerball-pen ink is water-based, while ballpoint-pen ink is oil-based). The key word is “flexible”: Silver-particle-based conductive inks have been around for a long time, but they are made for use on rigid substrates. In contrast, the new ink can be used on paper and the paper folded back and forth (to a bend radius of 0.5 mm) thousands of times before the ink fails. This makes the ink well suited for rollable and flexible displays.

When rolled on with a 12 µm thickness, the ink has a very low electrical resistivity of 1.99 × 10-4 ohm-cm, which can be lowered further to 4.34 × 10-6 ohm-cm by annealing it. The silver content is 45–55% by weight, the corresponding viscosity is 1–10 Pa-s, and the binder is hydroxyethyl cellulose, a material commonly used in cosmetics and other household products. Using the nanoparticle-based ink in a rollerball pen allows application of the ink directly to paper or other rough surfaces quickly, at low cost, and without programming. Among other things, the researchers demonstrated a flexible LED display on paper, conductive text, and 3D radio-frequency antennas. Contact Jennifer Lewis at [email protected].