LIDAR: Photon-counting 3D imaging lidar measures biomass and the cryosphere

Compared to conventional waveform-digitizing altimeters or laser time-of-flight lidar techniques, photon-counting lidar is a more efficient technique as it requires only one detected photon to make a range measurement rather than hundreds or thousands. Sigma Space Corp. (Lanham, MD) has taken advantage of this ranging sensitivity to develop its single-photon counting lidar system, which can be operated day or night with two to three orders of magnitude greater efficiency and spatial resolution than conventional multiphoton-threshold or waveform-based lidar systems.

At a compact 2.5 cubic feet and 73 lb, the photon-counting lidar system collects the photons returned from 100 individual beams generated by splitting the 523 nm output of a Q-switched Nd:YAG microchip laser with a 10 × 10 diffractive optical element (DOE). The power in each of the 100 beams is approximately 1 mW–50 nJ at the 20 kHz laser repetition rate. Single-photon surface returns from the 10 × 10 array of laser beamlets are imaged by a 3-in.-diameter telescope onto corresponding anodes of a 10 × 10 segmented-anode microchannel-plate (MCP) photomultiplier tube, which are in turn output to individual channels of the timing receiver. Each channel can respond to multiple stop events with a deadtime of only 1.6 ns. As a result, each laser pulse provides a 3D 100-pixel image. Finally, an optical scanner is matched to the ground speed of the host aircraft, and the 3D images are mosaiced together to create a contiguous topographic map of the desired area.

At a mean ground velocity of 161 km/h and an altitude of 1 km, the imaging spatial resolution is 15 cm horizontal and <5 cm vertical. At this altitude, the system can image a 524 m swath of ground, collecting 3D data at a maximum rate of 2 Mpixels/s.

Biomass and the cryosphere

The photon-counting 3D lidar system has successfully measured biomass and the cryosphere during NASA-sponsored flight tests conducted over calibrated tree farms in the Eastern United States and in the vicinity of the Jakobshavn glacier in Greenland. Both measurement types are important to NASA’s overall program to study global climate change.

The cryosphere encompasses those portions of Earth’s surface where water is in solid form: namely, snow-capped regions, glaciers, ice sheets, and permafrost. The high reflectance from cryosphere surfaces—typically 0.8 to 0.96 over ice and snow for the 532 nm operating wavelength—increases the solar noise count rate. Nevertheless, the single-photon lidar was able to image 40-m-deep crevasses within the glacier and the bottoms of glacial melt ponds to a depth of about 15 m from altitudes up to 2.5 km.

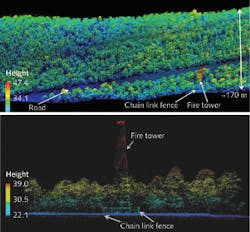

For biomass measurements, the single-photon sensitivity, sub-nanosecond pulsewidths, high measurement density, and low deadtime (<2 ns) of the detector and receiver electronics create a structurally detailed rendering of forested areas from the raw point-cloud data, enabling technically and economically sound methodologies for measuring and mapping carbon emissions due to deforestation and forest degradation (see figure).

“We are presently reconfiguring our current 100-beam 3D imaging lidar for autonomous operation in a Viking 300 unmanned aerial vehicle for a NASA customer,” says John Degnan, chief scientist at Sigma Space Corp. “Within the next year or so, we also hope to demonstrate a wide-swath [up to 4.8 km], 100-beam scanning lidar operating at altitudes up to 50,000 ft.”

REFERENCE

1. J. Degnan et al., “Cryosphere and Biomass Measurements using a Photon-Counting 3D Imaging Lidar,” 2011 Conference on Lasers and Electro Optics (CLEO), paper ATuA3, Baltimore, MD (May 3, 2011).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.