PHOTONICS APPLIED: MID-IR SENSING: DFB laser diodes expand hydrocarbon sensing beyond 3 µm

LARS HILDEBRANDT and LARS NÄHLE

Tunable diode laser spectroscopy is a versatile technique for the detailed characterization of gas compositions. The types of constituents and their concentrations, for example, can be determined with high accuracy by making use of the unique absorption features of each gas species. However, TDLS is critically dependent on the availability of suitable laser sources for the designated gas-sensing applications. Monomode DFB laser diodes in the near-infrared (NIR) wavelength range up to around 3 µm have successfully been used in a multitude of industrial applications in the past, and technologically relevant gas species in those applications include water (H2O), carbon monoxide (CO), carbon dioxide (CO2), and ammonia (NH3).

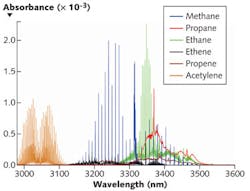

Application-grade monomode lasers for TDLS beyond the 3 µm limit have—until recently—been unavailable, posing a severe limitation for sensing applications especially considering the detection of hydrocarbons. Many hydrocarbons have strong absorption features in the mid-infrared (MIR) wavelength range between 3.0 and 3.5 µm where their fundamental absorption bands can be situated (see Fig. 1).1 Performing TDLS on the basis of those absorptions, with line strengths often orders of magnitude stronger than those of corresponding NIR absorptions, enables hydrocarbon detection with formerly unattained precision.

One of the most interesting hydrocarbon applications is accurate process control in the petrochemical industry, which can lead to higher energy efficiency and pollutant reduction. A major advantage of using laser spectroscopy on hydrocarbons in the MIR compared to currently used techniques such as gas chromatography is the possibility of real-time analysis with TDLS. Thanks to recent developments by nanoplus within the European project SensHy (www.senshy.eu), DFB lasers with application-grade performance for highly sensitive TDLS hydrocarbon detection in the 3.0-to-3.5-µm MIR wavelength range are now commercially available.

DFB laser technology

To fabricate its monomode DFB laser diodes, nanoplus uses a proprietary technology based on lateral metal grating structures.2 The gratings—with dimensions on the order of 100 nm—are defined next to the sidewalls of etched ridge waveguide structures using high-precision electron beam lithography (see Fig. 2).3 The feedback structures are then patterned by metal evaporation, resulting in DFB laser devices.This cost-effective DFB laser diode fabrication approach has been used for more than 10 years and eliminates the need for epitaxial overgrowth in the device layers, thus avoiding impaired laser performance due to patterning-induced defects near the active region. Now nanoplus has commercialized application-grade DFB laser diodes with operation wavelengths up to 3.5 µm (in the MIR wavelength range).

For optimum operation in TDLS applications, an epitaxial process based on active type-I quantum wells embedded in quinary barrier material is used. In addition, DFB device processing based on this material is customized for high performance; namely, the laser ridge waveguides are surrounded by a gold layer of high thermal conductivity for improved heat removal and equipped with a highly reflective backside metal coating for increased optical output efficiency (see Fig. 2 inset).

The long-wavelength DFB devices are exactly matched to their designated applications in TDLS sensing and subsequently mounted on TO headers with internal temperature controllers. Hermetic sealing of the headers in a dry nitrogen atmosphere yields application-ready, packaged DFB laser devices that are typically capped with a sapphire emission window, which is transparent in the wavelength range of interest.

Hydrocarbon detection beyond 3 µm

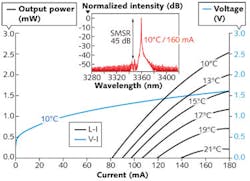

Representative L-I curve data at different Peltier-controlled chip temperatures for the DFB devices at 3.36 µm (see Fig. 3)reveal continuous-wave, room-temperature operation comparable to devices operating at lower wavelengths, with output powers in the milliwatt range. The DFB devices suppress side modes by more than 40 dB (for one example of monomode operation at 10°C and 160 mA; see Fig. 3 inset), making them well suited for accurate TDLS sensing.By adjusting the Peltier controlled chip temperature, the DFB emission wavelength of the lasers can be coarsely tuned to the desired value for the designated application with a tuning rate of approximately 0.28 nm/K. Single absorption lines and their shapes may then be scanned with very high precision and speed by current modulation of the emission wavelength (approximately 0.025 nm/mA) to sense gas absorption features in a range of several nanometers.

In one example, TDLS of acetylene was performed with a 3.06 µm DFB laser. Acetylene (C2H2) is an impurity in the cracking process used to manufacture ethylene (C2H4), the hydrocarbon produced in the largest volume worldwide. For the petrochemical industry, it is important to monitor the acetylene content with high accuracy to ensure a certain purity and thus quality of the produced ethylene.

The acetylene fraction can be removed through a hydrogenation process by converting it to ethylene in the following reaction:

C2H2 + H2 → C2H4

To avoid an incomplete conversion of the C2H2 or an undesired continuing conversion of the C2H4 to ethane (C2H6), the optimum conditions for the hydrogenation process may be determined by real-time monitoring of the C2H2 concentration.

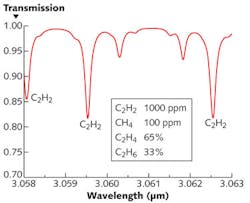

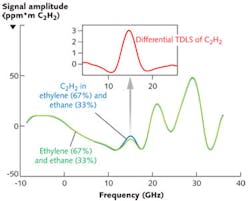

According to spectroscopic data, acetylene absorption lines around 3.06 µm are isolated and free from interfering absorptions due to a hydrocarbon background typical of a hydrogenating reactor (65% C2H4, 33% C2H6, 100 ppm CH4). A computed absorption spectrum in this range for 1000 ppm C2H2 in the reactor background for an interaction length of 10 cm at a temperature of 25°C indicates that this wavelength region can therefore be used for the monitoring of C2H2 (see Fig. 4).1In addition to hydrocarbon sensing for the petrochemical industry, real-time monitoring of explosive gas concentrations has huge implications for an improvement in workplace safety. The early detection of gas leaks in the industrial and private sector is just one of many applications that will benefit from longer-wavelength MIR DFB devices.

REFERENCES

1. P. Kluczynski et al., Appl. Phys. B: Lasers and Opt., 105, 2, 427–434 (2011).

2. W. Zeller et al., Sensors, 10, 2492–2510 (2010).

3. L. Nähle et al., Electron. Lett., 47, 46 (2011).

Lars Hildebrandt is director of sales and Lars Nähle is a research and process development engineer at nanoplus GmbH, Oberer Kirschberg 4, D-97218 Gerbrunn, Germany; e-mail: [email protected]; www.nanoplus.com.