ULTRAFAST LASERS: Free-space CPA approach uses volume holographic gratings

JAMES CARRIERE and FRANK HAVERMEYER

Over the last two decades, high-power ultrafast lasers have become an enabling technology for numerous industrial, scientific, and biomedical applications. Typical approaches for producing very high peak powers with diffraction gratings or fiber Bragg gratings (FBGs) are either bulky or limited in their power-handling capability.

Achieving high powers in short picosecond or femtosecond pulses can be difficult due to nonlinear effects that occur when concentrated high-power pulses propagate inside the gain medium of the amplifier. For many applications, chirped volume holographic gratings (VHGs) are able to provide the perfect combination of high power-handling capability with an extremely compact size, and are now enabling new ultrafast laser designs in a variety of applications.

Chirped pulse amplification

The chirped pulse amplification (CPA) technique was developed by Strickland and Mourou in 1985 to reduce the localized intensity of the pulse during amplification.

The most common approaches to CPA use diffraction grating pairs, FBGs, or chirped VHGs. In each case the low-energy seed pulse is stretched to hundreds of picoseconds, greatly reducing the power density of the beam during amplification so that higher total pulse energies can be achieved. Recompression of the amplified pulse then restores the initial pulse length, with a greatly increased peak power.

A typical configuration for a CPA system uses either VHGs or dispersive gratings as the stretcher and compressor elements (see Fig. 1). The length of the grating region written in the fiber for an FBG is comparable to the length of the VHG, but the total length of the fiber is typically meters long, meaning that the system dimensions are determined by the minimum bend radius of the fiber, which can easily be several times larger than the length of the VHG.

The stretcher and compressor elements are designed to apply a linear phase delay across the bandwidth of the pulse. The stretcher elements increase the pulse length to approximately 300 ps so it can be more efficiently amplified.

The phase delay of the stretcher and compressor elements have opposite signs such that short wavelengths are delayed in one grating (normal dispersion for positive chirp) while long wavelengths are delayed in the other (anomalous dispersion for negative chirp). By matching the dispersion profile of the stretcher and compressor, the amplified pulse will have the same spectral and temporal characteristics as the seed pulse but with much higher power.

Comparing CPA technologies

Diffraction gratings, FBGs, and VHGs each have their own advantages and disadvantages when it comes to CPA of ultrafast lasers.

Diffraction gratings are able to withstand very high pulse energies since they are free-space elements and the light can be distributed over a large area. This makes them rather bulky (often tens of centimeters in size) compared to FBGs and VHGs. In addition, ordinary diffraction gratings can easily lose 50% of the energy after four reflections in a typical grating stretcher/compressor system. To reduce this loss, special transmission gratings must be fabricated with electron-beam lithography that add significantly to the cost. Grating compressors also introduce higher-order phase errors that can limit the quality of recompression.

Fiber Bragg gratings are more compact but confine the pulse energy to the fiber core during propagation, resulting in very high power densities. If the pulse energy exceeds around 1 µJ of energy, nonlinear effects such as self-phase-modulation or Raman scattering begin to significantly affect the spectral properties of the pulse and limit their ability to recompress it. At very high power levels, catastrophic breakdown of the fibers will occur. To minimize these nonlinear effects in the fiber amplifier, long stretched pulses on the order of 1 ns are required.

Volume holographic gratings are free-space elements that overcome some of the space- and power-handling limitations of the other techniques, but have some limitations in terms of bandwidth and pulse length. Typical VHGs have dimensions on the order of 2 × 5 × 30 mm3, making them much more compact than diffraction grating pairs and providing much higher efficiency (approximately 90%).

The free-space operation of VHGs also enables much higher power densities (on the order of tens of watts or hundreds of microjoules) than FBGs. However, their range of operation is somewhat constrained by the physical dimensions of the glass and the maximum index change that can be induced during recording of the grating. For example, the length of the grating determines the maximum stretched pulse length. This translates to approximately 300 ps in single-pass configuration for a 30-mm-long grating. The functional spectral bandwidth is determined by both the length and achievable induced index modulation, which currently limits the minimum compressed pulse duration to roughly hundreds of femtoseconds. Ultimately, VHG-based CPA systems require fewer components, are simpler to align, and are less expensive to implement and operate.

CPA-based ultrafast laser applications

High-power ultrafast lasers are especially useful in laser machining and cold ablation of nearly any material. Traditional millisecond to nanosecond lasers rely on localized heating, melting, and vaporization of the material, limiting their use on thermally sensitive materials. The applied thermal stresses also produce uneven edges and micro-cracks that can create failure mechanisms. But the pulse duration of ultrafast lasers is short enough that there is minimal thermal transfer to the material (or a small “heat-affected-zone”), while the peak intensity is high enough to create multiphoton absorption interactions that can be used to ablate nearly any material.

A common application is ophthalmic surgery where ultrafast lasers are currently being used as microkeratomes to create a flap in the cornea for laser-assisted in situ keratomileusis (LASIK) procedures and to perform anterior capsulotomy, lens fragmentation, and corneal incisions for cataract surgery. The ability to ablate organic materials combined with the precision machining properties of ultrafast lasers also enables medical device manufacturing such as the creation of polymeric bioresorbable cardiovascular stents.

Ultrafast lasers also find wide use in semiconductor and microelectronic manufacturing applications. For example, they are used in the dicing of thin silicon wafers that are so flexible they become a challenge for traditional dicing machines. Flat-panel display and solar panel manufacturing pose similar challenges in the machining and patterning of ultrathin panels and integrated thin films. Laser cutting and drilling of printed circuit boards presents another opportunity for ultrafast lasers to enable further miniaturization of electronic devices.

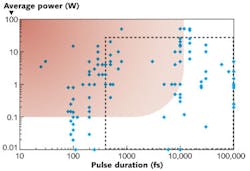

Beyond microelectronics, there are also heavy industrial applications for ultrafast lasers, which include optimizing fuel injection systems in the automotive industry and fabrication of microstructures to help reduce friction on ship hulls for antifouling. This wide range of applications has created sufficient demand for dozens of companies to provide ultrafast lasers and supporting products (see Fig. 2). While VHG-based CPA systems are only applicable to a portion of this applications space at present, the performance is sufficient for many important applications that significantly benefit from their compact form factor and high efficiency.Chirped VHG performance

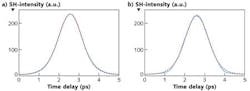

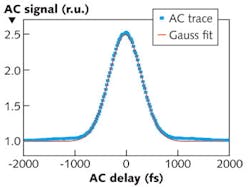

VHGs can enable a significant increase in the average power of CPA systems while maintaining both pulse duration and mode quality. A performance comparison for a sub-picosecond laser using a dispersive-grating-based CPA system and a VHG-based system containing Ondax PicoPulse pulse stretcher and compressor gratings shows almost identical near-transform-limited pulses after recompression (see Fig. 3).Typical CPA systems with VHG stretchers and compressors are also able to achieve near-transform-limited performance (see Fig. 4). For a 250 fs input pulse that is stretched and recompressed using two VHGs with nearly identical spectral profiles, the output pulse duration of 530 fs demonstrates that VHGs are the ideal solution for compact, high-power handling ultrafast systems in the hundreds of femtoseconds to low picosecond range.

James Carriere is director of business development and Frank Havermeyer is director, advanced technology development at Ondax, 850 E. Duarte Rd., Monrovia, CA 91016; e-mail: [email protected]; www.ondax.com.