OPTICAL DATA STORAGE: Holographic data storage uses volumetric crystal media

Access Optical Networks (AON; Monmouth Junction, NJ) has developed several technologies for holographic data storage (HDS) with write-only, read-only, and rewrite capability in a volumetric crystal media. The new nonvolatile-memory HDS products are designed to have a storage density of 1.2 terabytes (Tbytes), with read/rewrite performance of 1 Gbit/s. The company is currently seeking partners to commercialize the HDS products, which will initially target cloud computing, high-performance computing, enterprise, and solid-state device applications.

Volumetric storage

In the AON HDS method, an optical signal from a coherent laser source is split into separate data and reference beams that travel two separate paths before they are directed into a volumetric storage medium. A proprietary device placed in the reference beam serves to control its phase, enabling on/off switching, hologram writing, and erasure. A second proprietary device enables rapid addressing to a selected multiplexed angle when writing and also later, when searching and accessing an individual hologram. All holograms are stored near 90º for greatest diffraction efficiency. Finally, the data beam is reflected from the individual micromirror surfaces of a microelectromechanical-systems (MEMS)-type spatial light modulator (SLM) that transports the information to be stored into the photorefractive crystalline material.

Principal advantages of the AON method include volume rather than surface holographic storage, with greater than an order-of-magnitude layer depth in the storage medium compared to holographic disks; angle multiplexing of a large number of holograms within a 1-cm-cube crystalline medium to store more than 1 Tbyte of data; selective erasure of portions of individually stored holograms by external computer control—essential for data storage applications; and scalability to >10 Tbyte density and read/rewrite performance exceeding 10 Gbit/s while concurrently reducing the form factor and power requirement compared to conventional optical storage methods.

AON is currently storing digitized parallel data in rectangular 1000 × 1000 (1 million) arrays within the crystal volume and using the latest CMOS camera readout methods. This parallel recording and readout of a million bits at a time enables the rapid data-transfer rates in holographic storage. And the ability to multiplex or superimpose images throughout the volume enables the enormous storage-density capabilities of holographic storage.

MEMS-enabled storage

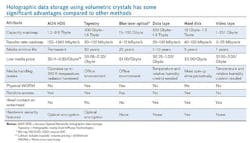

To date, most HDS manufacturers such as General Electric (GE; Fairfield, CT) and InPhase Technologies (Longmont, CO) have focused on spindle disk media. In addition to being slow write and read devices, these are also write-once-read-many (WORM) devices with limited market applications. The advantage of the spindle disk approach was to benefit from the existing mechanical architecture and infrastructure. Another advantage included the ability to use low-power lasers because of the relatively thin disk media. However, HDS in volumetric crystal media can scale performance by more than an order of magnitude beyond the most competitive spindle-disk-media-based electronic non-volatile storage solution available today (see table).

Success of the AON HDS system is possible thanks to the availability of enabling MEMS devices, including high-reflectivity SLMs that can paginate a small-form-factor, continuous-wave laser beam with high fidelity, speed, and accuracy, producing multilevel grayscale-encoded holographic images within volumetric crystal media.

The AON HDS system incorporates a 90° geometry angle multiplexing optical signal-processing technology that increases data rate and recording density. The method is designed to record and uniquely address a large number of data pages composed of clusters and sectors. The selective erase enables the rewriting of previously used data-storage locations in the storage media. And the 90° geometry angle multiplexing enables faster data access, eliminating the latency and seek time associated with spindle disk media. In addition, the low-mass MEMS devices provide higher reliability with less susceptibility to shock and vibration.

“We are currently seeking strategic partners to collaborate in completing the development of our holographic data-storage technologies,” says Glenn Gladney, president and CEO of AON. “Our products offer a 300 K radiation-hardened storage medium that can be clean-erased in minutes.”

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.