ULTRAFAST OPTICS: Tilted retroreflector array alters ultrafast temporal pulse shape

A micro-optical retroreflector array is at the heart of a device developed by researchers at the Max-Born-Institut für Nichtlineare Optik und Kurzzeitspektroskopie (Berlin, Germany) and the Fern Universität Hagen (Hagen, Germany) that temporally shapes femtosecond laser pulses.1 The ability to create pulses with a tailored temporal shape has benefits for applications such as pump-probe spectroscopy, coherent control, and optical information processing.

While existing approaches—which include direct space-to-time pulse shapers working in the Fourier or Fresnel domain, digital micromirror arrays combined with an interferometer, and others—require complex optoelectronic components and software or suffer from dispersive pulse distortion, the new approach is simple, compact, and dispersion-free.

Array of retroreflecting grooves

Intended to shape near-infrared (NIR) pulses with durations on the order of 10 fs, the technique is based on dividing the pulse into numerous parallel propagating subpulses by reflecting it from an array of miniaturized retroreflector grooves. In the geometric-optics approximation and with exact 90° reflector angles and a collimated beam, each incoming light ray is exactly redirected by the double reflection.

If the retroreflector array is tilted with respect to the beam, then the resulting optical path lengths for light passing through adjacent retroreflecting channels are significantly different from one another, causing time delays across the retroreflector. For large enough tilt angles, the subpulses are completely temporally separated (multiplexed), whereas for smaller angles the subpulses partially overlap, allowing pulse shaping. The number and signal ratio of active channels are adjusted by altering the spatial parameters of the illuminating beam.

The experimental retroreflector array was fabricated from aluminum via diamond machining and has a period of 640 μm and a total number of 19 prismatic grooves. The tiltable array mount has an angular resolution better than 0.01°, which corresponds to a travel time difference of 0.7 fs.

The pulse source is a Ti:sapphire laser oscillator from Femtolasers (Wien, Austria) with a pulse duration of 10–12 fs, a 790 nm center wavelength, a maximum spectral width of 120 nm full width at half maximum (FWHM), a 250 mW average power, an 80 MHz repetition rate, and a beam divergence of about 0.1°. To start, the pulses were reflected along the prism axis of the retroreflector for no relative delay, and at a 45° angle of incidence in the other (non-delaying) axis.

The normalized autocorrelation signals of temporally processed pulses were measured as a function of the tilt angle of the retroreflector. For large angles between 6° and 20°, multiple pulses were obtained; the autocorrelation signals indicated the formation of double subpulses with a maximum delay of 1.4 ps, corresponding to a minimum repetition frequency of 0.7 THz.

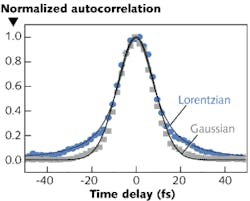

On the other hand, a small tilt angle on the order of 0.1° produced a time delay of about 5 fs and resulted in temporal pulse-shaping. Applying two slightly different tilts resulted in approximate Lorentzian and Gaussian autocorrelation temporal pulse shapes, respectively (see figure).

The most important advantages of the reflective micro-optical approach are its low dispersion, minimum damage risk, and compactness, resulting in stable pulse shaping. The researchers note that the illumination can be modified with an additional beam expander and the delay range extended by placing multiple retroreflecting arrays next to each other. Conversely, it should be possible to exploit the high sensitivity of the temporal response as a function of tilt by taking advantage of small angular deviations well below 0.1°.

The researchers are investigating fabricating the retroreflectors using the LIGA (lithographie, galvanoformung, abformung; or lithography, electroplating, and molding) process, and are experimenting with shorter (6 fs) pulses, as well as with actively changing the pulses’ lateral intensity profiles using spatial light modulators for further control of temporal pulse shaping. They also wish to try out a light source consisting of an array of quasi-nondiffracting sub-beams.

ACKNOWLEDGMENT

Laser Focus World has a partnership with Advanced Optical Technologies to bring readers coverage of the journal’s content.

REFERENCE

1. R. Grunwald, M. Bock, and J. Jahns, Adv. Opt. Technol., 97, doi:10.1515/AOT-2011-0008 (2012).

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.