ENDOSCOPY: Dual-wavelength method brings zoom capability to microendoscopy

Most optical endoscopes for light delivery and in vivo imaging of biological tissues have a fixed field of view (FOV) and resolution, primarily because they use a graded-index (GRIN) or other lensing method that typically prohibits the use of optomechanics to enable zoom capability, due to the overwhelming need for miniaturization. But researchers at Cornell University (Ithaca, NY) have developed a clever dual-modality 9X zoom optical endoscope with no moving parts that will significantly expand the usefulness of microendoscopy.1

By simply switching the wavelength of the excitation light, the user can switch between a high-magnification, high-resolution, small-FOV multiphoton fluorescence modality and a low-magnification, low-resolution, large-FOV one-photon reflectance modality. The device should prove extremely useful in a clinical setting where large-FOV imaging could be used to identify a tissue area for study, followed by immediate small-FOV and high-resolution imaging to reveal cellular details at sites of interest on the tissue, for example.

Zoom optics

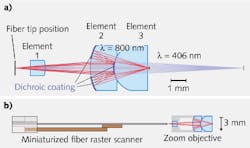

The dual-modality microendoscope consists of a three-element optical system (see figure). The first element simply focuses the light slightly from the delivery/scanning optical fiber. The light then passes through the second element onto a multilayered, patterned dichroic coating at the center of the third element. Depending on the wavelength, the (800 nm) light is either reflected to the dichroic coating on the upper and lower portion of the second element and then focused to the sample with high numerical aperture, or the light (406 nm) is transmitted and focused through the third element to the sample with low numerical aperture.

This 3-mm-diameter “zoom” objective is then paired with a miniaturized resonant/nonresonant fiber raster scanner. The scanner is basically two scanning optical fibers glued together: 1) a hollow-core photonic-bandgap fiber that transmits light at 800 nm for high-resolution multiphoton imaging and 2) a standard singlemode fiber that transmits 400 nm light for large-FOV, one-photon imaging.

Imaging studies were performed by coupling 800 nm femtosecond pulses into the hollow-core fiber and continuous-wave 406 nm light from a laser diode into the standard fiber. Using US Air Force test targets, the full-width half-maximum (FWHM) lateral resolution of the high-magnification mode was approximately 0.8 μm with a 150 μm FOV, while the FWHM lateral resolution of the low-magnification mode was approximately 4.5 μm with a very large 1.3 mm FOV. The dual-modality capability of this system has been experimentally demonstrated using unstained ex vivo mouse lung tissue, with excellent imaging results.

REFERENCE

1. D.G. Ouzounov et al., “Dual Modality Microendoscope with Optical Zoom Capability,” CLEO 2012 conference, postdeadline paper ATh5A.2, San Jose, CA (May 2012).