Indium gallium nitride (InGaN) laser diodes have reached a new frontier in performance: continuous-wave (CW) emission at green wavelengths longer than the 532 nm output of frequency-doubled Nd:YAG lasers. The previous long-wavelength record had been set by a 527 nm diode from Sumitomo Electric (Osaka, Japan). Now, a team from Sumitomo and the Advanced Materials Laboratory of Sony (Atsugi, Japan) reports diodes emitting more than 100 mW CW at wavelengths beyond 532 nm, and CW emission of unspecified power at 536.6 nm.

The success of these researchers could be a milestone in laser display and projector development. Doubled neodymium lasers can be used, but they require external modulation. Green laser diodes are more attractive, especially for mobile devices, because they can be directly modulated, are smaller, and can be more efficient. Laser-projector developers have been seeking 50 mW in the green with a wall-plug efficiency of 4.5%, according to Shimpei Takagi of the Sumitomo Semiconductor Technologies R&D Laboratories and colleagues.1

They also want diode wavelengths emitting in the 530–535 nm range, rather than the 515–520 nm of today’s commercial green laser diodes. For most applications, a 10 nm shift in wavelength would be of little importance, but laser projection is an exception because of the importance of green light in human vision.

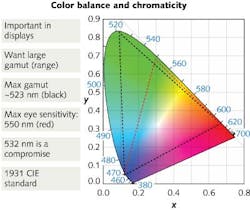

One reason for this is that color-sensing cones in the eye have their peak response at 555 nm in the green, matching the peak in the solar spectrum at Earth’s surface. A second is that color perception depends on the relative response of the eye’s color receptors, and the green and red receptors are closely spaced, peaking at 540 and 570 nm, respectively. That response makes the green wavelength used in a laser projector particularly important in determining the gamut, or range of colors, that can be displayed. As shown in the International Commission on Illumination (CIE) diagram (see figure), the color gamut is largest for wavelengths of about 523 nm, but the optimum wavelength for displays is offset to 530–535 nm by the eye’s higher sensitivity to longer wavelengths.

Semipolar planes

The challenge has been growing good-quality diodes containing the roughly 30% indium needed to reach the 520–530 nm band. Commercial InGaN laser diodes are grown on the substrate’s hexagonal C plane, which is strongly polar, so electric fields separate electrons and holes. That increases emission wavelength without adding more indium but at the cost of reducing recombination rate and emission efficiency.

One alternative is growth on the nonpolar M planes orthogonal to the C plane, but diode fabrication has proven difficult. Sumitomo and other developers, including Corning (Corning, NY), Soraa (Freemont, CA), and the University of California at Santa Barbara, have taken a compromise approach. They grow diodes on semipolar planes at a 45° angle to both the C plane and the crystal axis, where growth is easier and efficiency is higher, although more indium is needed.

Now Takagi and colleagues report reaching CW 100 mW InGaN diodes at record long wavelengths grown on semipolar GaN substrates. They fabricated a series of ridge waveguide lasers, 2 μm wide and 500 μm long, emitting at different wavelengths. They measured output of 167 mW at 525.1 nm, 107 mW at 532.1 nm, and 75 mW at 535.7 nm. They also observed CW operation at 536.6 nm but did not report the power, presumably because it was below the 50 mW they consider necessary for laser projectors.

High wall-plug efficiencies

The researchers report wall-plug efficiencies of 7.0% to 8.9% at 525 to 532 nm, well above the minimum goal for projectors, and improvement over their earlier semipolar lasers. “Improvement of the slope efficiency was the key factor for obtaining higher output powers,” says Takagi. Reducing threshold voltages from 6.4 V in earlier laser diodes to 4.7 V also contributed to higher wall-plug efficiency. They also measured powers to 90 mW from a 528.1 nm laser operated at 80°C, indicating their lasers could be used in portable devices with limited heat-sinking and high internal temperatures.

Katsunori Yanashima of Sony’s advanced materials laboratories and colleagues reported more good news: long lifetimes for similar semipolar InGaN laser diodes emitting at 527 to 530 nm.2 Extrapolating from tests lasting about 1000 hr, they estimate that lasers emitting 50 mW should have lifetimes longer than 5000 hr, and lasers emitting 70 mW should have lifetimes of at least 2000 hr.

Those results “look pretty impressive, especially the reliability data,” says Peter Zory, a veteran laser-diode developer at the University of Florida (Gainesville, FL). Soraa and Corning also are actively developing semipolar InGaN, although they have yet to report results matching Sumitomo’s. The next challenge will be commercial production.

REFERENCES

1. S. Takagi et al., Appl. Phys. Expr., 5, 082102 (2012).

2. K. Yanashima et al., Appl. Phys. Expr., 5, 082103 (2012).

Jeff Hecht | Contributing Editor

Jeff Hecht is a regular contributing editor to Laser Focus World and has been covering the laser industry for 35 years. A prolific book author, Jeff's published works include “Understanding Fiber Optics,” “Understanding Lasers,” “The Laser Guidebook,” and “Beam Weapons: The Next Arms Race.” He also has written books on the histories of lasers and fiber optics, including “City of Light: The Story of Fiber Optics,” and “Beam: The Race to Make the Laser.” Find out more at jeffhecht.com.