HIGH-POWER FIBER LASERS: Doping management leads to better fiber-laser output

To create a short-pulse fiber laser with simultaneous high-average-power output and high peak powers presents a conundrum. Increasing average power requires minimizing thermal effects, which leads to longer gain fibers with lower doping; however, increasing peak power requires minimizing nonlinear effects, which leads to shorter fibers with higher levels of doping.

Researchers at Bilkent University and FiberLAST Inc. (both in Ankara, Turkey) and TÜBITAK Ulusal Metroloji Enstitüsu (Kocaeli, Turkey) have created a forward-pumped short-pulse fiber laser in which the amount of dopant varies along the fiber.1 In analogy to dispersion management of fibers, the researchers call their technique “doping management.”

At the beginning of the fiber’s last amplifier stage, where the amplifier output is lower and pump level is at its highest, the fiber has low doping to reduce thermal load. Further along, where output is greater and pump level is lower, the fiber is more heavily doped, minimizing gain length to reduce nonlinear effects. Because it is difficult to create a fiber in which doping level varies continuously, the researchers created a prototype with two differently doped segments (more can be used later).

Experiment matches simulations

In the experimental setup, a modelocked ytterbium (Yb)-fiber oscillator provides seed pulses at a 100 MHz repetition rate. The amplifier itself has three stages (with the last high-power stage being the multisegment fiber). The first stage, which is core-pumped, produces 2.7 ps pulses at an average power of 100 mW. The second stage is a double-clad (DC) fiber pumped by a 10 W laser diode and produces 5.2 ps pulses at 1 W average power.

The third stage, which is pumped with a five-port pump-signal combiner, contains a 1.8 m section of DC Yb 25-μm-core∕250-μm-cladding fiber (6.5 dB/m doping absorption at 980 nm) spliced to a 1.6 m section of high-doped Yb 25-μm-core∕250-μm-cladding fiber (10.8 dB/m doping absorption at 980 nm). Total fiber length in the system is 19.3 m.

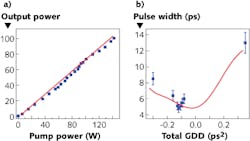

The experimental power scaling fits closely to a computer simulation, with a maximum average output power higher than 140 W measured (see figure). The measured pulse duration as a function of total group-dispersion delay (GDD) matches well with simulations. Using prechirping, the researchers obtained pulse lengths as short as 4.5 ps at a total GDD of 0.12 ps2, limited by nonlinear effects.

Future versions

Using more than two fiber segments in the high-power amplifier stage can further improve operation. “We are developing detailed numerical calculations (led by Amira Tandirovic and Parviz Elahi in my group) to optimize number of segments versus collected benefits,” says F. Ömer Ilday of Bilkent University. “For most applications, it seems that four segments is a good compromise between complexity and benefits.”

However, discrete segments aren’t the final word in doping management. “We are talking to fiber manufacturers about the possibility of having variable doping,” notes Ilday. “Despite the increased complexity, this could be considered for high-end applications, particularly for kilowatt-level, narrow-linewidth continuous-wave fiber lasers for beam combining.”

REFERENCE

1. P. Elahi et al., Opt. Lett., 37, 15, 3042 (Aug. 1, 2012).

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.