FREQUENCY COMBS: Frequency combs assist plasma-sterilization measurements

It has long been known that partially ionized states of matter—plasmas—can be used to sterilize particular bacteria and disinfect surfaces. But to determine which plasma sources and mixtures of bactericidal species are most effective at the sterilization process, the concentrations of molecular gases such as hydrogen peroxide (H2O2), ozone (O3), nitrous oxide (N2O), and nitrogen dioxide (NO2) that are present in a plasma effluent must be measured.

Since standard Fourier-transform infrared (FTIR) spectrometers require long measurement times to yield molecular spectra with sufficient signal to noise ratio, researchers at JILA (a joint institute of the University of Colorado and the National Institute of Standards and Technology or NIST, both of Boulder, CO), the University of Colorado (Denver and Aurora, CO), and Super Pulse (Ithaca, NY) are instead using frequency combs for significantly faster and real-time gas measurements, bringing these novel broadband sources further into the realm of biomedical optics and biophotonics.1

Plasma generation

Both indirect (remote) or direct (treatment area is in close proximity) plasma generation methods have been tried in antibacterial applications. The researchers created a plasma-induced effluent using a dielectric-barrier discharge (DBD) with H2O2 additives. To contain the free radicals and reactive oxygen species generated by the plasma, a closed-loop flow system was used. The effluent flow rate is 118 liters per minute, and a 50% H2O2 solution bubbler is used actively with the DBD for maximum bactericidal action.

Frequency comb measurements

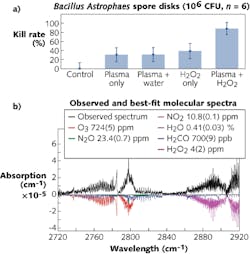

Direct frequency-comb absorption spectroscopy was applied to measure the plasma-produced gas concentrations that maximized the “inactivation” percentage for the bacteria under test (see figure). The light source in the experiment was a mid-IR optical parametric oscillator pumped by a high-power, femtosecond ytterbium (Yb) fiber laser at 1064 nm, creating a 150 nm broadband spectrum continuously tunable between 2.8 and 4.6 µm. The plasma effluent flows through a multipass Herriott cell in the flow path, with an interaction length of 18 m between the optical beam and gas sample. Light exiting the multipass cell is analyzed using a fast-scanning Fourier-transform interferometer.

Gas concentrations are derived from a fit of a sum of known molecular spectra from the HITRAN molecular database; measurements are made in about 1 s.

“Direct frequency-comb spectroscopy allows measurements of concentrations of many molecular species simultaneously in real time as the gas sample is flown through the cell,” says Aleksandra Foltynowicz, who is now assistant professor at Umeå University, Sweden. “The mid-IR frequency-comb source provides access to the so-called molecular fingerprint region where strong fundamental molecular transitions are located, so a wide variety of species can be detected with high sensitivity. This technique will have a large impact on applications where fast noninvasive multispecies detection is needed, such as breath analysis or atmospheric research.”

The cold plasma technology is being commercialized by Super Pulse for use in dental handpiece sterilization and infected wound therapy.

REFERENCE

1. M. Golkowski et al., IEEE Transact. on Plasma Sci., 40, 8, 1984–1991 (August 2012).

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.