ORGANIC CRYSTALS: Stilbene crystals improve neutron detection

Under US Department of Homeland Security (DHS) contract HSHQDC-12-C-00020, Inrad Optics (Northvale, NJ) and Lawrence Livermore National Laboratory (LLNL; Livermore, CA) have cooperated to increase both the size and commercial availability of the organic scintillator stilbene (a carbon-hydrogen crystal with the chemical formula C14H12).

Well-known as a material for fast-neutron (1–20 MeV) detection in a gamma-ray background, stilbene, when fabricated using melt-growth crystal techniques, has traditionally not yielded enough material for widespread, low-cost, commercial neutron-detection applications. But LLNL has recently demonstrated economical and high-quality solution growth of stilbene and is transferring the process to Inrad Optics for large-scale production.1

The work on large, high-quality stilbene is an outgrowth of an ongoing activity at LLNL funded by the US Department of Energy’s National Nuclear Security Administration to explore new materials for fast-neutron detection and study the science underlying the solution growth technique.

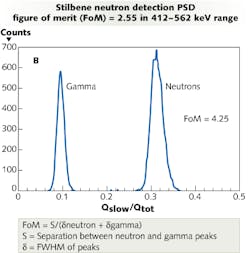

The process of neutron or nuclear-material detection in a gamma-ray background through scintillation occurs as particles strike the scintillation material and emit either photons or particles. By analyzing differences in the pulse shapes of the fluorescence signals obtained when high-energy neutrons and gamma rays strike a scintillation material like stilbene (in a process called pulse shape discrimination or PSD), neutron interactions can be uniquely detected. These fluorescence signals are recorded from the scintillation detector using a photomultiplier tube (PMT).

Crystal growth

Unlike melt processes, the solution-grown stilbene process employs crystallization tanks and seed holders that were constructed to handle organic solvents and improve the growth process using controlled temperature reduction with rotation. Solution growth of stilbene has already produced boules with vertical and horizontal dimensions of 4 in. The solution-grown boules have a so-called “x-ray rocking curve” full-width at half-maximum below 20 arcsec, indicating excellent crystalline quality.

Neutron detection using stilbene has in the past been limited by the availability and cost of the stilbene crystalline material; but with this Phase II small business innovation research (SBIR) contract, Inrad Optics has fabricated commercial-grade, 1-in.-diameter cylinders (3 in. maximum length) and anticipates fabrication of 2 in. cylinders by the end of 2012. Dimensions of packaged stilbene detectors are application-specific, although standard dimensions of 1-in.-across, 1-in.-high cylinders and 2-in.-across, 2-in.-high cylinders can couple to common PMTs.

Crystal properties evaluated at LLNL using a californium-252 source for finished neutron detectors show good neutron-gamma discrimination, with a PSD figure-of-merit in the 412–562 keV range of 4.25, which is comparable to, and often exceeds, the typical values obtained with the best melt-grown crystals of approximately the same size (see figure).“The solution method used for stilbene production is based on technology developed previously for growth of super-large KDP [potassium dihydrogen phosphate] crystals for NIF [the National Ignition Facility],” says Natalia Zaitseva, LLNL physicist and principal investigator in the DHS-funded stilbene development project at LLNL. (Incidentally, LLNL, with Inrad participation, holds the record for the growth of the largest KDP crystals produced on a commercial scale). Zaitseva adds, “The prior KDP technique has been substantially modified to adjust to growth of large pure organic crystals, of which stilbene is the first developed for commercial production.”

REFERENCE

1. “Production of Stilbene for Fast Neutron Detection,” Inrad Optics white paper (2012), http://bit.ly/XnJzfw.

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.