SPECTROMETERS: SWIFTS spectrometer technology miniaturizes and increases performance

In many spectrometer designs, there is often a tradeoff between miniaturization and high performance. Spectrometer miniaturization typically results in lower performance and vice versa. Fortunately, improvements in optoelectronic component manufacturing and integrated nanotechnologies are challenging this tradeoff mentality. Resolution Spectra Systems (Grenoble, France) has developed its miniature, high-performance Zoom Spectra spectrometer using stationary-wave integrated Fourier-transform spectrometry (SWIFTS) technology with a spectral resolution of 0.005 nm in an 8 × 8 × 12 cm housing at measurement rates up to 30,000 Hz, and even smaller chip-based OEM spectrometer “engines” in development that achieve 0.1 nm resolution in a 2 × 2 mm chip.1

Incorporating SWIFTS

The SWIFTS technology is based on a near-field Lippmann architecture—similar to methods being developed for optical data storage—in which evanescent waves within a waveguide are directly sampled using a collection of optical probes. The evanescent waves are created as the input signal interferes either with itself (in a true Lippmann configuration) via a mirror placed at the end of the waveguide cavity, or in a counterpropagative method as two optical signals introduced at opposite ends of the waveguide cavity interfere with each other. Miniaturized local detectors (nanodetectors) placed on top of the waveguide gather just a small fraction of the standing evanescent wave interferogram for spectral analysis.

The SWIFTS spectral resolution (R) is based on classical Fourier spectrometry and is defined as the length of the detected interferogram in the cavity, or R = λ/Δλ = 2nL/λ, where λ is the wavelength, Δλ is the wavelength resolution of the spectrometer, n is the refractive index of the waveguide, and L is the waveguide length probed by the nanodetectors. For a singlemode waveguide, the spectral resolution is practically unlimited; for example, nanodetectors placed over a 1 cm waveguide at 600 nm would result in a 15 pm resolution—far better than any commercial, even “standard-sized,” spectrometer instrument.

The recoverable spectral range over which the spectrometer operates, however, is limited by the physical distance between two consecutive nanodetectors and the spectral range over which the waveguide remains singlemode. Spectral range or bandwidth is specified at 5–14 nm at a 630 nm wavelength to achieve the 0.005 nm resolution figure for the instrument, but can be as broad as 400–500 nm in a multiplex architecture using parallel waveguides.

The spectrometer incorporates a 28-μm-long, few-micron-diameter waveguide processed in a glass substrate. The nanodetectors are nanometer-sized patterns spaced a few microns apart on the waveguide surface.

Targeted applications

The extremely high resolution and small size of the SWIFTS-powered spectrometer makes it useful for applications in tunable laser control and laser measurement, fiber Bragg grating (FBG)-based component measurement, and high-depth optical coherence tomography, among other industrial and environmental applications.

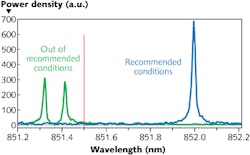

Analysis of a tunable laser diode illustrates how high spectral resolution and high-rate measurement are critical to high-performance spectrometer operation (see figure). The SWIFTS instrument measured a tunable distributed-feedback laser with a nominal center wavelength of 852 nm. A scan of the laser between 851.200 and 853.180 nm showed the single-mode peak over the specified operating temperature of 15º to 40ºC. But when operated outside the nominal conditions between 5º to 15ºC and measured at a low frequency of 100 Hz, the laser became dual-mode. Further analysis at a higher measurement frequency above 1000 kHz showed that neither mode appeared at the same time, indicating a mode-hopping laser. This dual-mode and mode-hopping discrimination is only possible to study with a high-resolution, high-frame-rate spectrometer.

“We are actively pursuing developments that achieve a large optical aperture input and address low-signal applications,” says Christophe Bonneville, president of Resolution Spectra Systems. “Being able to operate our miniaturized instrument outside of a laboratory setting will enable numerous in situ and in-production spectroscopic measurements.”

REFERENCE

1. Resolution Spectra Systems web site, ZOOM Spectra product page; http://bit.ly/Rm654R.

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.