Parallel single-walled CNTs form high-performance IR photodetector

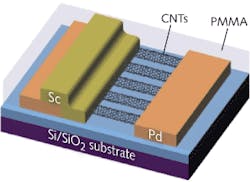

While carbon nanotubes (CNTs) have some properties (high infrared absorption, picosecond response, and ballistic electron transport) that could make them excel for IR photodetection, they are difficult to handle and fix in place in large quantities. Researchers at Peking University (Beijing, China) and Duke University (Durham, NC) have come up with a geometry that allows for large numbers of single-walled CNTs to be both held in place and easily electrically contacted at both ends of the nanotubes. In the setup, many parallel semiconducting CNTs lay flat in a position normal to the incoming IR light direction on a silicon (Si)/silicon dioxide (SiO2) substrate; the CNTs are contacted en masse on one end by a palladium (Pd) electrode and the other end by a scandium (Sc) electrode, then encased in PMMA polymer for durability. The two metals have different work functions, making ohmic contacts with the valence and conduction bands of the CNTs, respectively.

Many parallel interdigitated electrode fingers can allow the creation of a larger detector area; for example, 10 × 20 µm. The prototype detector had a responsivity of 9.87 × 10-5 A/W and a detectivity greater than 107 cm·Hz1/2/W for light at 785 nm. Increasing the CNT count and the quality of the CNTs could boost these numbers to 10 mA/W and 108 cm·Hz1/2/W, respectively, say the researchers. Contact Sheng Wang at [email protected].

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.