QUANTUM-CASCADE LASERS: QCLs enable applications in IR spectroscopy

PETROS KOTIDIS

Following their first demonstration at Bell Labs in 1994 by Federico Capasso (now at Harvard University) and Jerome Faist (now at ETH Zurich), quantum-cascade lasers (QCLs) reached commercial maturity and viability in the early 2000s. One of the prime reasons for such success has been the wide availability and increased reliability of the metal-organic chemical vapor deposition (MOCVD) and molecular beam epitaxy (MBE) machines used for QCL production, a result of heavy development and investment during the rapid growth of the telecommunications industry.

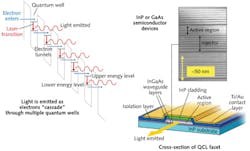

Quantum-cascade lasers are different from traditional semiconductor laser diodes, which use p-n junctions for light emission. Instead, QCLs have multiple active regions, which are composed of a multilayered semiconductor material structure, specially designed to have the appropriate electronic bands. These layers are manufactured with extreme precision down to nanometer thickness, hence the need for MOCVD-like machines. Injected electrons "cascade" through the layers of the active regions, emitting multiple photons, enhancing the laser gain, and providing a wide range of wavelengths (see Fig. 1).

Today, there are three classes of QCLs in the market: ultrawidely tunable, narrowly tunable, and high power but narrowly tuned. To achieve some of these characteristics, QCL gain media are sometimes integrated in an external-cavity configuration, where a wavelength-selecting component, such as a diffraction grating, is used to provide the laser tuning. Under such configuration and with the proper coatings on the facets of the gain medium, these lasers can provide ultrawide tunability and have enabled some very exciting new applications.

Spectroscopy and the IR fingerprint region

One of the technologies benefiting from the use of these lasers is infrared (IR) spectroscopy. For more than a century, IR spectroscopy has been used to chemically characterize substances by absorption or transmission; more specifically, the spectrum in the 5–14 μm range, part of the so-called "fingerprint region," provides strong and unique (fingerprint-like) characteristics for many substances.

While lasers have long provided dramatic benefits for IR spectroscopy, prior to the invention of QCLs there were no commercially available lasers that could provide light across the fingerprint region in the mid-IR. Fourier transform IR (FTIR) spectrometers have been the standard equipment used for decades to obtain the spectral characteristics of substances, but new QCL-based spectroscopic instruments have significant benefits over these devices.

Quantum-cascade lasers are orders of magnitude brighter than other coherent sources in the fingerprint region, providing enough brightness for standoff, noncontact sensing, and analysis of highly absorbing or scattering targets. The output facets of QCLs are small enough that the light they emit can be imaged to essentially diffraction-limited spots, enabling the analysis of miniature targets at long distances (up to hundreds of meters) and the coupling to small-diameter fibers with very small optical coupling loss.

In contrast to a Raman spectroscopic instrument, there is no need for a high-power excitation laser in a QCL system; as a result, for most applications a high signal-to-noise ratio (SNR) is achieved with lower-power QCLs. The high brightness of QCL sources results in sufficient SNR to eliminate the requirement for high-sensitivity cryogenic detectors and thus the nuisance of a liquid nitrogen supply. The QCL itself is cooled with a standard thermoelectric cooler (TEC), allowing for battery operation. The result is a system with essentially no moving parts, low power consumption, and small optics, enabling handheld field instruments.

Field and laboratory

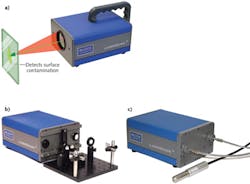

Block Engineering recently introduced the first fully integrated handheld IR spectrometer (the LaserScan analyzer; see Fig. 2). Based on eye-safe QCLs operating in the 5–14 μm spectral range, this instrument provides real-time characterization of chemical substances at a standoff distance of 6–12 in. Visible pointers aligned with the invisible QCL illuminate the laser spot (approximately 2 × 4 mm) on the surface, and built-in algorithms enable real-time detection and characterization of substances. Both trace and bulk amounts of substances can be detected to levels as low as 0.5 μg/cm2 out in the field.Spectrometers based on QCLs can also be used in laboratory settings, in applications ranging from chemical synthesis and drug development to heterogeneous catalysis and tribology. Block also introduced a QCL spectrometer for such applications (the LaserScope IR Spectrometer, see Fig. 2); this instrument houses electronics, laser control, and optical components in a single box. Laser light emerges from one port and is detected by a separate port in the system, allowing the placement of optical accessories, sampling equipment, or pointing mirrors in front of the instrument. Infrared optical fibers can be directly attached to the ports to enable probe-based (for example, attenuated total reflection) measurements or coupling to an optical cell for analysis of gases or liquids.

Both these instruments use a high-repetition-rate (up to 1 MHz) QCL that has a peak pulse power up to 200 mW and an average power up to 10 mW. All electronics, laser control, and optical components are housed in a single box, as shown in Fig. 2, which could be easily interfaced with any desktop or laptop computers. Key specifications include wavelength accuracy better than 0.5 cm-1, wavelength repeatability better than 0.1 cm-1, power variation less than 0.05% over 10 ms, beam divergence better than 5 mrad, pointing stability better than 0.5 mrad, and spectral resolution of 1–2 cm-1.

Noncontact, standoff applications

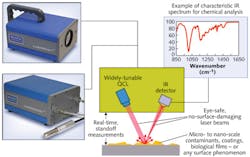

Many spectroscopic applications in the fingerprint region can take advantage of standoff detection (see Fig. 3). For example, in pharmaceutical cleaning verification, a handheld LaserScan can be used to scan the walls of production vessels to ensure that they have been properly cleaned between production batches. In parts manufacturing, residual silicone, oil, or other lubricants or contamination can be detected on surfaces of production parts to determine which may need to be further cleaned for subsequent processes such as painting or coating. And for painting and coating applications, QCL spectroscopy allows chemical analysis of surface layers: for example, the characterization of special osteophilic coatings that are applied on the surface of orthopedic implants to improve acceptance of the implants by human tissue.Other noncontact applications include atomic-force microscopy (AFM), in which QCLs can be used to provide additional chemical information. In the area of heterogeneous catalysis, surface-reaction phenomena are analyzed to better understand and improve the catalyst's characteristics; here, the surfaces of these materials are usually at very high temperatures (hence no contact-measurement option) and are highly optically absorbing, requiring the use of high-brightness QCLs. In tribology (the study of friction), surface phenomena are characterized so that the lifetime of high-performance lubricants can be improved.

A particularly well-known need for noncontact measurement arises in efforts to protect against explosives and chemical-warfare agents; detection of trace and bulk chemical threats is in high demand, as the world experiences increasing terrorism threats.

Open-path and on-line gas sensing

The high beam quality of QCLs enables long path lengths that are useful for the protection of large indoor and outdoor facilities such as transportation terminals, chemical plants, refineries, and military bases. For example, a QCL-based system scans the air inside an airport terminal; the eye-safe beams detect the release of airborne chemical threats (see Fig. 4a). A similar system is used for on-line monitoring of gases in pipes for process control (see Fig. 4b). In some cases (such as this one), optical windows and reflectors allow for real-time analysis without the need for sampling the gas or providing sampling pipes.Infrared microspectroscopy

A potential breakthrough application for QCL-based spectroscopic instruments is in IR microscopy. A diffraction-limited focused spot (on the order of 5 μm in size) produced by a QCL leads to high-sensitivity chemical analysis of microscopic targets. Numerous applications exist for this enhanced form of microspectroscopy, including analysis of human or animal cells for cancer detection, detection and classification of bacteria and other biological threats, forensics analysis of microscopic samples (for example, hair samples or blood stains), identification of miniaturized contaminants on semiconductor products, and analysis of miniature organic contaminants on surfaces.

Petros Kotidis is CEO of Block Engineering LLC, Marlborough, MA; e-mail: [email protected]; www.blockeng.com.