TEST & MEASUREMENT: Profiling solar energy in concentrated solar power systems

Concentrated solar power (CSP) has been a promising technology because of its high performance in electrical or heat conversion applications. As far as performance goes you cannot achieve much more efficiency than concentrated solar power in applications ranging from concentrated photovoltaics to high-temperature industrial heating.

Concentrated solar technology systems use optical elements to focus a large area of sunlight onto a small area. The concentrated light is then applied as direct heat or as a heat source for electrical power generation. Concentrating solar technologies exist in several common configurations, primarily dish optics and solar power towers. Moreover, concentrated solar power is the preferred technology for high-efficiency solar cells.

Concentrated solar power is divided into distinct technologies: dish/engine systems and heliostats-based solar power towers.

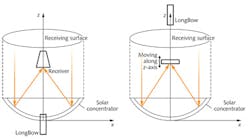

Dish/engine systems—A large segmented parabolic mirror structure collects the solar energy and focuses it on a receiver/engine, suspended at the mirror's focal point. The system is activated by a very accurate tracker to follow the sun. The receiver/engine absorbs the solar energy and heats gas, which is used to drive a Stirling engine/generator that produces the electricity. A mirrored paraboloid is similar to a very large satellite dish, and it is usually composed of many smaller flat mirrors formed into a dish shape (see Fig. 1). Alternative technology suspends a combination of high-efficiency solar cells with water cooling to produce electricity and hot water.

The key performance criteria for a dish solar concentrator are the degree of concentration and its interaction with the receiving elements. The degree of concentration is indicative of the degree to which the mirror elements are properly aligned, conforming to the desired parabolic shape. Careful analysis of direct sun flux and its mapping will prevent meltdown and inefficient energy extraction. This analysis will include the following parameters: flux mapping and distribution at several positions along the optical axis; tracking accuracy along sun trajectory; and hot spots.

Heliostats-based solar power towers—A power tower system uses a large field of flat, sun-tracking mirrors known as heliostats to focus and concentrate sunlight onto a receiver on top of a tower. A heat-transfer fluid heated in the receiver is used to generate steam, which in turn is used in a conventional turbine generator to produce electricity. Some power towers use water/steam as the heat-transfer fluid. Other advanced designs are experimenting with molten nitrate salt because of its superior heat-transfer and energy-storage capabilities. The energy-storage capability, or thermal storage, allows the system to continue and dispatch electricity during cloudy weather or at night. Measurement requirements are similar to the dish configuration although in a totally different environment and target.

Measuring CSP efficiency

In a CSP system, concentrated solar photovoltaics use lenses to focus direct sunlight onto high-efficiency solar cells. Fresnel concentrating lens are widely used for economical reasons, but other solutions have gained popularity in various applications. Through concentration, the required silicon cell area needed for a given amount of energy is reduced and substituted by a low-cost lens element. Small quantities of very efficient, expensive, multijunction cells are used to convert the sunlight into electricity. Two-axis tracking is required to maintain maximum efficiency.

It is important to measure the flux distribution of solar concentrating systems to optimize the receiver configuration and the power distribution across its input aperture. Different techniques have been developed to measure the flux distribution in a plane placed at the focal zone. However, the wide variety of focal plane distributions combined with very high flux level pose challenges for a measuring instrument (see Fig. 2).

Recent developments of CCD-based beam characterization instruments, combined with sophisticated optics, allow the detailed evaluation of the power density distribution in the focal region of the concentrator and thus optimize the design of solar concentrators. Factors of manufacturing, assembly errors, or variations of sunlight might yield poor results, such as a larger spot in the focal region, nonuniformity of heat distribution on the receiver, or local hot spots. These phenomena have a significant impact on the overall system parameters.

There is a distinct interaction between key components and solar flux. The durability of key components such as the solar receivers is affected by the use of flux homogeneousity, reduction of thermal stress, and reduction of peak flux. Obtaining a homogeneous flux can improve the power efficiency and lifespan while reducing thermal stress and possible damages to the receiver surface.

A starting point for optimizing the solar power distribution in a real solar system is strongly related to the ability to measure and characterize the beam distribution and compare it to the optical concentrator's design. For some simple cases, the form of the dish surface can be designed analytically, but usually an iterative process of design and measurement is required.

Measurement methodology

A measurement method we have developed is capable of characterizing and analyzing concentrated solar beams, and providing exact data to the following parameters:

• solar flux distribution at the focal point region

• the best location along the optical axis for mounting the solar receiver

• real-time measurement of solar tracking accuracy

• numerical comparison of several distributions

The concentrated solar flux is measured optically by a calibrated CCD camera that records the Sun's image on a Lambertian target. The Lambertian target may be actively cooled when necessary.

Various types of concentrators produce different peak temperatures and correspondingly affect thermodynamic efficiencies because of differences in the way they track the sun and focus the light. For example, the Duma Optronics BeamOn LongBow system is a measurement station based on a CCD-type beam profiler, supplemented with high-magnification optics and computing technology. It is a beam diagnostics measurement system for real-time measurement and display of CSP.

The typical measuring system consists of: a digital camera with a spatial resolution of 736 × 484 pixels; a Lambertian target; a motorized zoom lens with automatic focus; and a laptop computer with USB 2.0 attachment and application software. A diffuse Lambertian target is placed at the focal plane, and the LongBow system is used to pick the created Lambertian image and create a distribution of the solar energy at the focal plane (see Fig. 3).

The system displays irradiance isosurfaces for the examined beam and displays the results in false colors. Then the total beam size is calculated at various levels and clearly displayed. The concentrator is assumed to have the focal axis on a vertical position, and the incidence of solar radiation is parallel to the focal axis of the dish. The deviation from this assumption is given as X-Y position deviation from the assumed zero point, which is also the deviation from perfect tracking.

First, the energy concentration is calculated on a plane located perpendicular to the focal axis, at its geometrical center. Later, it is possible to scan along the axis of symmetry from the concentrator's focal point as shown in Fig. 2. This procedure gives us a set of planes where irradiance distributions are known. Therefore, we will be able to calculate the best nondamaging position for mounting the receiver, according to the receiver specification and the real solar flux as measured by the system.

For application on a heliostats-based solar power tower, where the target is large and remote, the reflected Lambertian beam is imaged remotely and analyzed by the same system at a different zooming position to yield best results. Similar calculations with different calibration factors are performed to derive major parameters such as intensity profiles, beamwidth, beam position, and beam shape.

We use a beam characterization system to measure the distribution of concentrated sunlight on a target. The portable system acquires and processes images reflected from a diffuse or a Lambertian target. These images are proportional to the incident flux.

The beam characterization system allows us to measure the solar flux incident at the focal plane of the thermal or concentrating photovoltaic receiver. The instrument could be used extensively in high-flux solar applications. However, because the beam characterization system is portable, it is suitable for field application, as well as in manufacturing processes.

About the Author

Oren Aharon

Oren Aharon is the CTO of Duma Optronics. He has several decades of experience in the electro-optical field, including start-up initiations based on his patents. He founded Duma Optronics 25 years ago to offer advanced enabling technologies to industry. He owns 30 patents and graduated from Technion with a BSc in nuclear engineering and an MSc in industrial engineering. He has written numerous articles and served as a technical assistant to the Israeli Minister of Energy.