NOVEL FIBER-OPTIC COMPONENTS: Mode converter scales power in rectangular-core fiber amplifiers

In 2008, researchers at Lawrence Livermore National Laboratory (LLNL; Livermore, CA) analyzed the scalability of diffraction-limited fiber lasers, considering thermal, nonlinear, damage, pump coupling, and mode-field diameter (MFD) restrictions, and determined that fiber-laser amplifiers using conventional large-mode-area (LMA) and/or photonic-crystal (PC) fibers could output a maximum of around 36 kW with diffraction-limited beam quality.1 Many of those same researchers from LLNL have now proposed that rectangular-core fibers could extend single-aperture fiber-laser amplifier output to greater than 100 kW, and have developed a mode-converter system that will enable such scaling.2

Rectangular cores

The rectangular-core fiber is designed to support only the lowest-order mode in the thin ribbon dimension (y) and multiple modes in the wide dimension (x). However, only a single higher-order mode (HOM) is excited along the x dimension. Stable propagation of this mode is ensured by coiling the fiber only in the y direction and allowing a single HOM (in the x direction) to propagate in the rectangular-core fiber. The MFD of the fiber can then be controlled by increasing the waveguide width, simultaneously increasing the effective area of the fiber and guiding a HOM at power levels beyond those possible with circularly symmetric waveguides.

Another advantage of moving from circularly symmetric waveguides to ribbonlike rectangular-core fiber waveguides is delayed onset of thermal lensing. Peak intensity on axis is also significantly lower in the case of a ribbon fiber when compared to the HOM of circular-core fibers.

Mode converters

Because most seed lasers output a circular TEM00 mode, mode converters are essential for efficiently coupling that output into a rectangular-core amplification fiber. Furthermore, many high-power materials-processing applications need a diffraction-limited beam, requiring conversion of the amplified HOM in the rectangular fiber back into a TEM00 mode for beam delivery.

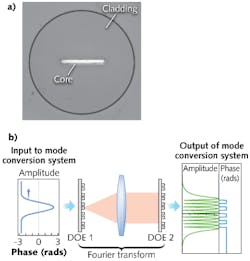

The LLNL mode converter for transforming the TEM00 mode output of a low-power (milliwatt-level) seed laser into a specific HOM profile of a rectangular-core fiber uses two diffractive optical elements (DOEs) or phase-only plates implemented using spatial light modulators (see figure).

The first DOE reshapes the Gaussian TEM00 mode into a multiple-lobed profile that matches the x, y HOM characteristics of the rectangular-core fiber. The second DOE is placed in a conjugate Fourier plane with respect to the first DOE, and the phase profile of the second DOE is chosen to ensure that the phase difference between each lobe of the desired HOM is flipped between 0 and π. The Fourier transform relates the electric fields in the two planes such that the DOE parameters (phase-plate profiles) can be modeled using the Gerchberg-Saxton (GS) algorithm. The measured mode-conversion efficiency into the HOM is around 84%.

The LLNL mode converter, operated in reverse, converts the HOM output of a commercially available rectangular-core fiber from Liekki (Lohja, Finland) with a 5 × 50 μm silica core (0.1 NA) and 125-μm-diameter circular cladding to a TEM00 mode. In this case, the authors used a combination of the GS algorithm and a genetic algorithm to find the optimized phase profiles for the two DOEs. The measured mode-conversion efficiency from the 7th HOM of the rectangular-core fiber to the Gaussian TEM00 output beam at 1053 nm was around 80%. The M2 value of this output is 1.27 and 1.07 in the x and y axes, respectively.

“In the future, phase plates fabricated in fused-silica glass can be used to build the mode converter to withstand the high-power output from rectangular-core fiber amplifiers,” says Arun Kumar Sridharan, staff physicist at LLNL. “These mode converters can also be leveraged for improved power extraction in bulk solid-state amplifiers.”

REFERENCES

1. J.W. Dawson et al., Opt. Exp., 16, 17, 13240–13266 (2008).

2. A.K. Sridharan et al., Opt. Exp., 20, 27, 28792–28800 (Dec. 17, 2012).

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.