METAMATERIAL OPTICS: Simple layered flat metamaterial lens focuses in the UV

A team of U.S. and Canadian scientists has created an easily fabricated sputtered-on flat thin-film metamaterial lens that works at UV wavelengths.1 The team includes scientists from the National Institute of Standards and Technology (NIST; Gaithersburg, MD), the University of Maryland (College Park, MD), Syracuse University (Syracuse, NY), and the University of British Columbia (Kelowna, BC, Canada).

The lens consists of alternating layers of metal and dielectric—in this case, silver (Ag) and titanium dioxide (TiO2) on the order of 30 nm thick—on a transparent glass substrate. The structure forms many strongly coupled plasmonic sheet waveguides that allow a transverse-magnetic-polarized (TMP) backwards electromagnetic mode with a frequency that falls between the bulk plasmon-resonance frequency of the metal and the surface plasmon-resonance frequency of the metal-dielectric interface; in this case, the researchers chose to work with light at 363.8 nm.

One-to-one 3D imaging

Because the metamaterial has a refractive index of -1, the incidence angle (with respect to the surface normal) of any ray passing into or out of it is flipped (multiplied by -1). The result is an unusual sort of image in which light from every point on one side of the lens is focused to a corresponding point on the other side of the lens that is exactly the same distance away from the lens, and also has the same lateral position; so, for example, an object point at (x, y, z) gets imaged to (x, y, -z). The result is a 3D mirror image of the object, always at unity magnification and without lens aberrations. Also, as a result, the lens has no optical axis and could in theory be made into an arbitrarily large sheet and still create images of the same high quality.

While the distances between the lens—which is only 450 nm thick—and the object and image are small (on the order of the lens thickness), the lens is a far-field imager, meaning that an image appears in free space, rather than on the lens surface.

On the metamaterial lens, which has both negative electric permittivity and negative magnetic permeability, the researchers deposited an opaque film of chromium (Cr) in which was patterned a 600-nm-wide illumination aperture. Through this aperture, they confirmed negative refraction for TMP light, along with conventional—and expected—positive refraction for transverse electric polarization.

Because linearly polarized light thus results in focusing only in one direction, the researchers actually use circularly polarized light for imaging experiments; light with a circular polarization has equal amounts of the two orthogonal linear polarizations (with a relative phase shift), so that, no matter what the orientation of the image feature, there is always some light available with the properly oriented polarization.

Imaging results

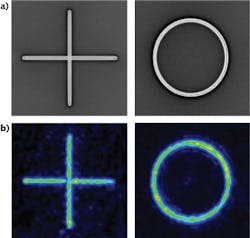

Finite-difference time-domain (FDTD) simulations for an ideal case showed a minimum beam width at focus of about 200 nm. However, a realistic amount of loss, dispersion, and other factors would be expected to degrade this. As an experiment, the researchers used a UV microscope objective to view an image created by the metamaterial lens of a 180-nm-wide slit (see figure). The result showed a minimum slit width of about 370 nm full width at half maximum (FWHM).

The NIST researchers and their colleagues took their inspiration from a theoretical metamaterial design recently proposed by a group at the FOM Institute for Atomic and Molecular Physics (Amsterdam, The Netherlands), adapting the design to work in the UV.

According to NIST researchers Ting Xu, Amit Agrawal, and Henri Lezec, aside from achieving record-short wavelengths, the metamaterial lens is inherently easy to fabricate. It doesn’t rely on nanoscale patterns, but instead is a simple sandwich of thin films, the construction of which is routine. And because its design consists of a stack of strongly coupled waveguides sustaining backward waves, the metamaterial exhibits a negative index of refraction to incoming light regardless of its incidence angle.

The metamaterial flat lens achieves its refractive action over a distance of about two wavelengths of UV light, making possible small image distances that are challenging to achieve with conventional refractive optics such as glass lenses. In addition, the researchers determined that transmission through the metamaterial can be turned on and off using higher-frequency (290 nm) light as a switch, allowing the flat lens to act as a shutter with a 50% intensity-modulation contrast (and no moving parts).

REFERENCE

1. T. Xu et al., Nature, 497, 470, doi:10.1038/nature12158 (May 23, 2013).

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.