WHITE-LIGHT SOURCES: Sapphire-core fiber produces broadband UV-visible light for OCT

A team of Taiwanese researchers has developed a very broadband (near-UV through the visible region) optical-fiber-based light source for uses in the bioscience and medical fields.1 Based on a glass-clad crystalline-sapphire fiber pumped by a near-UV laser, the source is potentially useful for optical coherence tomography (OCT), as well as fluorescence microscopy and flow cytometry.

The group, which includes researchers from National Dong Hwa University (Hualien), National Taiwan University (Taipei), and National Sun Yat-Sen University (Kaohsiung) demonstrated a fiber with a 1.16 mW optical output power (when pumped by a 325-nm-emitting helium-cadmium laser) at a 4.7% optical-to-optical efficiency and a white-light output with CIR chromaticity coordinates of (0.287, 0.333), which is a slightly blue-green shade of white.

Glass-clad sapphire

To fabricate the fiber, a 40-μm-diameter sapphire single-crystalline core was grown via a laser-heated pedestal growth (LHPG) technique in which a carbon dioxide (CO2) laser heats a large-diameter source rod, creating a molten zone from which a slightly hexagonal crystalline core is drawn. To create the color centers (oxygen-atom vacancies) and other spectral peaks in the sapphire on which the white-light generation depends, a small amount of titanium (Ti) and chromium (Cr) ions were added to the core.

The core was then inserted into a borosilicate glass tube with a 320 μm outer diameter and an inner diameter slightly greater than the sapphire core; the same CO2 laser setup was used to melt the glass and collapse it onto the core in a vacuum environment; this step also caused the sapphire to be regrown. An 18-mm-long segment of the fiber was used for white-light generation.

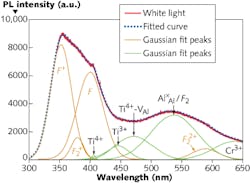

The fiber segment was wrapped in a tin-lead alloy and clamped in an aluminum heat sink. Up to 25 mW of laser light was focused by a 40X objective lens into the input end of the fiber to generate white light. The resulting output spectrum ranged from 300 nm out to past 650 nm (see figure).

Many possible photoluminescent (PL) bands can contribute to such a spectrum, including PL bands with peaks at 375, 420, 458, 485, 531, 577, and 648 nm that correspond to color centers, and bands associated either with Ti or Cr and which have peaks at 380, 420, 460, 480, 510, 590, and 650 nm. To determine which peaks actually contributed to the actual output, the researchers fitted a curve to the white-light spectrum, then, assuming Gaussian profiles for all the possible PL bands, did a best fit of the possible peaks to the overall curve. The result revealed a combination of color centers and effects of Ti and Cr ions, as well as aluminum vacancies filled by Ti.

The resulting high 4.7% conversion efficiency is the highest among existing active-waveguide white-light-producing approaches, including supercontinuum lasers, the researchers note.

REFERENCE

1. C.-C.Lai et al., Opt. Exp., 21, 12, 14606 (June 17, 2013).

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.