MOLECULAR IMAGING: QCLs enable mid-IR spectral image-based molecular detection

Using quantum-cascade lasers (QCLs) in a new standoff hyperspectral molecular-imaging system, Infrasign (Fremont, CA) has successfully detected trace amounts of protein in serum over a wide area with high sensitivity and specificity.1, 2

While chromatography and some spectral imaging techniques require an area to be physically swabbed to obtain a sample for molecular detection and analysis, Infrasign’s mid-infrared imaging spectroscopy (MIRIS) system noninvasively images over a large surface area at standoff distances from six inches to potentially several hundred meters using optically multiplexed QCLs and a microbolometer camera in a portable suitcase.

QCL multiplexing

To enable high sensitivity and specificity, three QCLs emitting at 6.1, 9.25, and 9.5 μm wavelengths at powers of approximately 11 mW are multiplexed into a single beam using a galvanometer mirror and beam-conditioning optics.

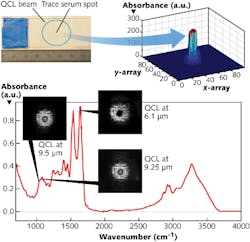

In applications such as surface biocontamination monitoring, a mid-IR laser beam is absorbed when it is tuned to an absorption peak of the biomolecules of interest, making the reflected region of an image containing those molecules dark against a light background (see figure).

A serum sample was prepared for protein analysis by smearing 5 μl of human serum over a piece of nonabsorbing tape punched with a hole and affixed to a calcium fluoride (CaF2) slide. The serum was then dried and the tape removed, leaving a stain on the slide. From a distance of 50 cm, a mid-IR microbolometer camera recorded the diffuse scattered signature reflected off an aluminum plate behind the slide as each 1.5-cm-diameter QCL beam independently illuminated the stain. The imaged data was then compared to spectral data from a commercial FTIR spectrometer system.

The dried serum spot was clearly visible as a dark spot when illuminated by the 6.1 μm QCL beam since that wavelength is strongly absorbed by the amide-I protein in the serum. Reduced absorption is seen at the glucose wavelengths of 9.25 and 9.5 μm in keeping with the results of the accompanying FTIR trace. In addition, the absorption ratio of amide-I/glucose of approximately 3.12 in the FTIR spectrum is close to the value of approximately 3.2 measured in the central pixel intensity values of the serum spot images.

With the major source of noise being the interference fringes in the image caused by the front and back surfaces of the slides, laser despeckling can improve the limit-of-detection (LOD) values.

Further experiments to assess the LOD values for MIRIS involved preparing serums with stepwise dilutions and analyzing the reflected images. The measured LOD of 3 μg/cm2 is, to Infrasign’s knowledge, the lowest LOD reported so far in any noninvasive image-based molecular recognition system—a value that could be improved to several hundred ng/cm2 with laser despeckling and improved image-processing algorithms.

“Infrasign’s first explosive trace detection product named SPOT (Sensitive Picture Of Traces)—recently supplied to the Department of Defense—is a three-QCL multiplexed explosive trace sensor capable of detecting trace elements of ammonium nitrate, TNT, urea nitrate, and sugar,” says Anadi Mukherjee, Infrasign president and CEO. “This system is capable of scanning at least a 6 × 6 in. area at a standoff distance of 8 ft.”

REFERENCES

1. A. Mukherjee, “Quantum Cascade Laser Imaging for Molecular Recognition,” Technology Transfer Showcase presentation at CLEO:2013, San Jose, CA (June 2013).

2. A. Mukherjee et al., J. Biomed. Opt., 18, 3, 036011 (March 2013).

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.