INTERFEROMETRY: Portable low-coherence holography creates 3D fingerprint images

HANIEL GABAI and NATAN T. SHAKED

When coherent light passes through or reflects from a sample characterized by different thicknesses and/or a different refractive index relative to its surrounding, phase retardation occurs. Hence, the extraction of the quantitative phase profile of the sample field can be used to produce a topographic map of the sample. In digital holography (DH), the quantitative phase and amplitude maps of the sample field can be numerically reconstructed from the digitally recorded interference pattern, created by superimposing a beam interacting with the sample and a reference beam coming directly from the light source. It is then possible to use numerical calculations to compensate for aberrations, refocus, or propagate to different axial planes.

By using new common-path, low-coherence interferometric setups and a smart design of the interferometric system, the levels of spatial and temporal noise are significantly decreased; as a result, conventional DH setups known for many years can be turned into powerful nanosensing platforms with the ability to sense subnanometric changes of thickness.

However, in spite of the potential for these techniques, most DH setups suffer from the same main drawbacks of bulkiness, nonportability, and the requirement for specific optical skills to align and use them, especially when employing low-coherence (broadband) light sources to decrease the level of noise and enable subnanometric measurements. These shortcomings cause this technology to largely remain in optical research laboratories, preventing its common use in industry or in medical clinics. Moreover, even in research laboratories, using these bulky and hard-to-align setups to achieve subnanometric measurements is a challenging task.

Our lab at Tel Aviv University develops compact, portable, inexpensive and easy to align DH techniques1-3 that enable quantitative, nondestructive and nonintrusive measurements and visualization of biological cells,2-5 drug release from biomaterials,6 and other elements with thicknesses that might vary between several nanometers4 to hundreds of microns.1 These unprecedented spatial and temporal measurement capabilities will not only enable basic research applications, but also carry great potential for clinical applications and industrial use.

Beamsplitter as interferometer

Fingerprint templates created from transparent gels are a challenging type of sample for DH imaging due to their relatively deep and complex topography, which creates difficult phase-unwrapping problems. To overcome these problems, we have designed a low-cost, simplified, and noise-reduced low-coherence interferometric imaging system that can produce accurate depth profiles of fingerprints and be operated by inexpert users.1

In the output of the imaging system, we have positioned a tilted beamsplitter that acts as a single-element interferometer. Because the object and reference beams propagate together, this common-path design is less sensitive to environmental noise factors such as mechanical vibrations and temperature fluctuations. In addition, the tilted positioning of the beamsplitter enables dual-channel imaging of two phase-shifted interferograms using a single camera. We averaged these two imaging channels in order to create a single and noise-reduced quantitative thickness image of the sample.

Additionally, we have used a low-coherence light source with a spectral bandwidth on the order of 6 nm. This significantly reduces unwanted parasitic coherent interferences, which may corrupt the original interferometric signal. In spite of the use of a low-coherence source, the interferometric alignment is simple and does not require difficult alignment: off-axis interferences are immediately obtained across the entire field of view of the camera.

To overcome phase-unwrapping problems, we used a two-wavelength phase unwrapping method that is capable of handling the fingerprint template's complex and deep topographies by acquiring the template using two close wavelengths and digitally creating a much larger wavelength. As a result, we were able to image deep fingerprint templates with thicknesses of several hundreds of microns.

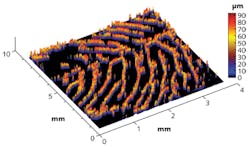

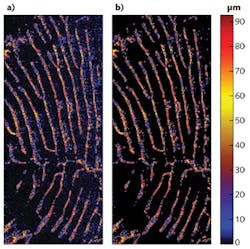

Quantitative phase imaging offers several unique advantages for fingerprint biometrics (see Fig. 1). By providing imaging of both two- and three-dimensional structures, identity theft and spoofing become more complex to achieve. In addition, blurring distortions, which are inherent in the creation process of simple fingerprint templates, can be easily repaired by thresholding on the sample thickness profile (see Fig. 2). This is not possible in traditional fingerprint template techniques using ink.The compact, inexpensive, and easy-to-align interferometric systems we develop, one of which is presented here, are expected to make DH imaging more accessible to inexpert users while significantly broadening its range of applications. Because of the off-axis geometry, no scanning is involved. Additional applications include imaging live cells without labeling, as well as profiling optical elements with thicknesses varying between several nanometers to hundreds of microns.

REFERENCES

1. H. Gabai and N. T. Shaked, Opt. Exp., 20, 4, 26906–26912 (2012).

2. P. Girshovitz and N. T. Shaked, Opt. Exp., 21, 5, 5701–5714 (2013).

3. N. T. Shaked, Opt. Lett., 37, 11, 2016–2019 (2012).

4. Y. Bishitz et al., J. Biophoton., 1–7 (2013); doi:10.1002/jbio.201300019.

5. P. Girshovitz and N. T. Shaked, Biomed. Opt. Exp., 3, 8, 1757–1773 (2012).

6. H. Gabai et al., Opt. Lett., 38, 13, 3017–3020 (2013).

Haniel Gabai and Natan T. Shaked are with the Department of Biomedical Engineering, Faculty of Engineering, Tel Aviv University, Tel Aviv 69978, Israel; e-mail: [email protected].