PHOTONICS APPLIED: INDUSTRIAL LASERS: The hole story: Femtosecond manufacturing improves automobile fuel efficiency

MICHAEL MIELKE

Automakers around the world are under pressure to meet increasingly stringent mileage requirements, so they are working on at least two fronts: to design drive-train systems that run on renewable or alternative fuels, and to wring more mileage out of existing fossil-fuel engine designs. On the latter front, researchers have found that better control of the spray pattern and droplet size from gas direct injectors (GDI) can have a dramatic impact on engine efficiency, improving performance by as much as 30%. While this discovery is exciting for automotive designers, it has proven maddeningly difficult to machine fuel injectors to the required dimensions and tolerances.

The legacy technologies—electrical discharge machining (EDM), mechanical stamping, and traditional laser drilling—could not achieve the level of precision needed to form injector nozzles that could manipulate fuel flow to specification. While traditional femtosecond lasers have demonstrated proficiency in one-step manufacturing of GDI nozzles, machining metal to specification in a lab is different than machining working automotive parts 24 × 7 in a factory environment.

Gas direct injection

In the U.S. and Europe, government-mandated automobile mileage improvements and emissions reductions, along with consumers' demands for powerful, high-performance engines, are forcing automobile parts manufacturers to advance their fabrication technologies. The U.S. government is mandating 54.5 average miles per gallon (MPG) by the year 2025, and the EU has defined an aggressive emissions reduction roadmap for the sake of environmental protection.1,2

In response, automobile manufacturers are rapidly switching from port fuel injectors (PFI) to the GDI format. In GDI engines, fuel is injected directly into the engine cylinder where combustion occurs. In contrast, PFI systems mix fuel and air upstream of the intake valve that brings the mixture into the cylinder. The advantage of the GDI architecture is that it increases engine power output while using a lean burn to reduce both fuel consumption and exhaust emissions.

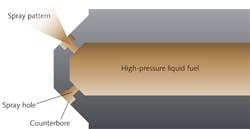

It is well-known by GDI design engineers that fuel flow, spray angle, drop size distribution, fuel mass distribution, and spray tip penetration—the factors that determine engine fuel efficiency and emissions rates—are directly controlled by the injector spray hole shape and interior wall surface roughness (see Fig. 1).3

These requirements have created an inflection point for the fuel injector manufacturing industry, whereby it must implement hole-drilling capabilities beyond what is sustainable with legacy techniques. Whereas traditional methods cannot achieve better than 0.5 μm average roughness (Ra) for the spray hole sidewalls or better than 3% hole-to-hole diameter variation, femtosecond laser drilling readily achieves 0.1 μm Ra and <1% hole-to-hole variation. Moreover, femtosecond laser technology is the only solution that provides both the newly required spray hole quality and achieves the required process throughput (<1 s per hole) to make each injector.

Femtosecond micromachining

Each femtosecond laser pulse focused onto the workpiece vaporizes a small volume of material without affecting the surrounding material and without melting, burring, or influencing the heat-affected zone (HAZ). There is only precise material removal for a higher-quality finished part.

Understanding how femtosecond lasers do this starts with a basic explanation of how traditional continuous-wave (CW) lasers machine materials. Laser light is simply a very intense, highly directional electromagnetic (EM) wave with a wavelength typically in the ultraviolet, visible, or infrared spectrum. When a laser beam hits a metal surface, the strong EM wave causes electrons in the metal to accelerate and collide with other electrons and the metal ions. The net product of all the collisions is rapid heating until the area under the beam simply melts away. Nearby, much of that heat diffuses into and damages the surrounding area.

When pulsed lasers with peak power >1 MW are used—as opposed to CW lasers—there is an even more intense EM wave that hits the material in a sequence of short flashes. The EM intensity is so high during each flash that electrons are not only accelerated, but many of them are actually ejected from the area of metal under the beam, and a high-pressure plasma forms from the ionized volume of material. Micro explosions relieve the pressure and create a fragmented spray of material from that ionized volume. Although material is removed by photoionization in this case, longer pulsed lasers (including nanosecond and picosecond pulsed lasers) still impose a large quantity of electron collisions and heat diffusion during the rising edge of each pulse, resulting in a significant HAZ.

This HAZ can be from tens of microns to hundreds of microns deep into the material surrounding the machined features and produces degraded material that must be removed using one or more post-processing steps such as manual honing, abrasive fluid machining, or acid etching. Post-processing steps typically reduce precision, increase cost, and lower production yield.

However, there is a seemingly impossible effect when machining metals with laser pulses having duration of hundreds of femtoseconds or less: the ionization and material removal occur efficiently with virtually no heat diffusion and no HAZ. The key is depositing all the laser energy faster than the material can respond through heat diffusion.

Metals have an effective thermal diffusion time of a few picoseconds. When the laser pulse width is much shorter than this time constant—down to the femtosecond range—machining of metals occurs in an apparently athermal process.

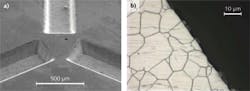

The result of this femtosecond laser ablation process is removal of material in a highly defined pattern, leaving the material that remains in pristine condition. Scanning electron microscope (SEM) images of three grooves milled into the surface of stainless steel using a 1552 nm femtosecond laser with 5 W average power and 700 fs pulse width at 100 kHz repetition rate (see Fig. 2) shows that the grain structure of the metal is unchanged all the way to the edge where the ablation took place, indicating that there is no sacrifice of material integrity and no need for post-processing steps to remove HAZ material.Hole drilling

Femtosecond lasers are now cost-effectively drilling precision holes in liquid atomization and spray systems. Hole diameters typically range from 100 μm to several hundred microns. The metal thickness has no lower limit as it does with mechanical processes and can be up to 1 mm thick. Hole aspect ratio is typically less than 10:1, since laser-beam focusing physics put a limit on the machining depth for a given hole-opening diameter due to clipping (diffraction) of the Gaussian beam at the entrance of the hole.

For drilling these holes, the femtosecond laser provides 10X more accurate and precise hole dimensions and higher control of machined surface quality than CW laser-drilled holes. This improves drilling capabilities with respect to circularity, cylindricity, taper, break and depth, and hole-to-hole consistency.

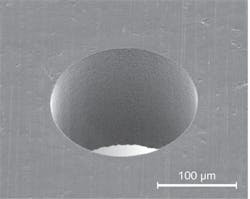

For a typical 200 μm diameter hole fabricated in 250 μm thick 316L stainless steel using a femtosecond laser, the hole has zero taper and the surface quality has average roughness Ra < 0.1 μm without post-processing steps. A 1552 nm, 10 W, 700 fs pulse width fiber laser operating at 200 kHz repetition rate with a beam spot size of 25 μm can drill a hole with these dimensions in <1 s (see Fig. 3). In contrast, traditional lasers do not achieve better than ±10 μm hole-to-hole size variation or less than 1 μm Ra without post-processing treatment in the form of abrasive fluid-flow honing.GDI requirements and new capabilities

Femtosecond laser solutions are currently used in GDI nozzle production by leading suppliers to the automotive industry. Common GDI designs typically have six holes per injector nozzle with diameter in the range of 200 μm, nearly 1:1 hole aspect ratio, and wall thickness in the range of 250 μm. These GDI injectors operate at relatively low liquid fuel pressure (<500 bar) as compared to diesel fuel injectors.

As fuel traverses out of the spray holes in GDI injectors, it rapidly transitions from a liquid jet to an array of droplets and finally to the atomized vapor that, along with the ambient gases inside the engine cylinder, comprises the combustion mixture. The injector spray hole's 3D geometry and sidewall smoothness directly impact the fuel spray pattern; for example, a non-optimized spray pattern may wet the engine cylinder walls with fuel droplets that may not participate in combustion and instead contribute to increased emission of hydrocarbons in the engine exhaust.

Successful criteria for drilling GDI fuel injector spray holes include a ±1.5% tolerance on the spray hole area and an average surface roughness (Ra) < 0.2 μm. These figures of merit are due to the ±1.5% tolerance on fuel flow—which is directly proportional to spray hole area—along with the requirement for a consistent droplet spray pattern. Although there are ways to achieve this tolerance by combining legacy machining tools with post-processing (like flow honing), these compound methods substantially increase manufacturing complexity and double cost.

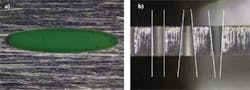

In addition to basic zero-taper circular hole drilling, femtosecond lasers enable elliptical-profile through-holes and circular through-holes with zero taper, positive taper, and negative taper (see Fig. 4). The elliptical hole reveals an approximately 5:1 aspect ratio (radii of 156 × 33.5 μm) and the tapered-hole angles are 0°, +6°, and -6°. Such capabilities are important for enabling finer control of spray pattern and direction—to ensure every last fuel droplet contributes to efficient combustion—as well as reduced wear and tear on the fuel injector surfaces, since fuel pressure and flow dynamics can be engineered to control cavitation and other effects.Industrial-grade solutions

The precise hole-drilling capabilities of the femtosecond laser alone do not make it a useful manufacturing tool; the demands of an automotive manufacturing environment require advances in fiber laser architecture, stability control, pulse management, remote diagnostics, and process optimization. Our R-Drill solution includes the industrial femtosecond laser and a five-axis trepanning beam scanner, with an f-theta focusing lens programmed with our precision hole-drilling algorithms. The R-Drill is typically installed in an enclosed workstation that includes debris evacuation and capture, on-axis purge gas (up to 10 bar of nitrogen, argon, or other gas) to quickly remove debris while the hole is drilled, and an automated motion system to position the blank injector nozzles at the focal plane of the scanner.

Industrial-grade femtosecond lasers have been proven cost-effective and potent by automobile manufacturers around the world. Advanced manufacturing capabilities enable new design freedom, and automotive engineers are now creating optimized fuel delivery strategies, such as more precise valve control, that will further drive adoption of femtosecond machining systems. Raydiance has demonstrated more than 700 distinct applications using femtosecond laser techniques, and 150 of those are just within the field of hole drilling.

REFERENCES

1. U.S. Department of Transportation, "2017 and Later Model Year Light-Duty Vehicle Greenhouse Gas Emissions and Corporate Average Fuel Economy Standards; Final Rule," 49 CFR Parts 523, 531, 533, 536, and 537 (2012).

2. Regulation (EC) No. 715/2007 of the European Parliament and of the Council of 20 June 2007 on type approval of motor vehicles with respect to emissions from light passenger and commercial vehicles (Euro 5 and Euro 6) and on access to vehicle repair and maintenance information (2007).

3. D. Hung et al., "Gasoline fuel injector spray measurement and characterization- a new SAE J2715 recommended practice," SAE Technical Paper Series 2008-01-1068 (2008).

Michael Mielke is chief scientist at Raydiance, 1450 North McDowell Blvd., Petaluma, CA 94954; email: [email protected]; www.raydiance.com.