FIBER-OPTIC SENSING: Low-noise fiber lasers enable far-reaching optical sensing

SØREN LØVGREEN

Interferometric fiber-optic sensing systems have become important tools for oil and gas exploitation, pipeline integrity monitoring, perimeter security, and wind detection. These sensing systems are gaining ground because they offer several advantages over traditional technologies based on electrical transducers such as piezoelectric hydrophones: fiber-optic sensing systems are passive (no electronics), compact, lightweight, reliable, and can be multiplexed to interrogate very large sensor arrays, as well as enable longer sensing ranges with high dynamic range and sensitivity.

In an interferometric optical sensing system based on, for example, coherent Rayleigh backscatter detection, the optical fiber typically acts as a long, continuous sensor that is extremely sensitive to acoustic perturbations from the surroundings. The small influences induced by the environment cause a change of the optical path length in the fiber; when interrogated by coherent laser light and recombined with unperturbed reference light from the laser source itself (the local oscillator in a coherent detection scheme) on a photodetector, an acoustic "fingerprint" is produced by means of data processing.

This fingerprint provides detailed information about an event at a specific location along the fiber. For perimeter surveillance, interferometric fiber-optic systems use sophisticated algorithms to discriminate background noise that can arise from such sources as rain droplets or aircraft, so that alarms are triggered only by relevant and potentially critical events.

In the oil industry and other industries such as water and wastewater transportation over long-range pipelines, the ability to monitor pipeline integrity and condition is critical. Due to their economic importance, these pipelines are also potential targets for intrusion; furthermore, mechanical cracks and fatigue can lead to enormous spills with severe economic and environmental consequences. Interferometric optical sensing systems offer preventive and accurate means to detect incidents or emerging mechanical failures so precautions can be taken at an early stage.

Low-noise laser source is key

The resulting demand for optical sensor systems has created a need for low-noise laser sources. NKT Photonics has been manufacturing low-noise, single-frequency fiber lasers since 1997 for global research laboratories, optical sensing system integrators, and the space and defense industries.

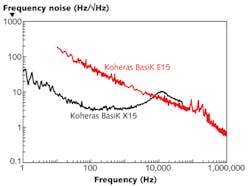

This type of fiber laser is a so-called distributed-feedback (DFB) design and is essentially a short and robust laser cavity. The high Q value and the relatively long length of the DFB cavity, combined with long radiative lifetimes of rare earth ions in silica, provide for fundamentally low values of phase noise and spectral linewidth. Careful packaging design and use of low-noise pump sources reduce effects of vibrations and acoustic noise, and technical noise. The result is a laser source that is compact, consumes little power, and is easy to use, with low phase noise and narrow spectral linewidth (see Fig. 1).

Low-noise lasers are now being deployed at different oil fields to interrogate large fiber-optic hydrophone arrays that pick up reflected acoustic signals from below the seafloor; the acoustic signals are generated from large air guns to help locate the oil.

More subsea systems are planned for the coming years, and currently fiber-optic land-based geoseismic systems with very high channel counts (toward an extremely high number of channels) are also being investigated. For all these systems, low noise is a key performance parameter to obtaining solid data and clear images, and in this game the laser phase noise plays a central role. The continued development of fiber-optic geoseismic systems therefore has helped push the laser technology toward compact, fiber coupled, high-reliability devices with unsurpassed low-phase-noise performance.

Wind lidar

Low-noise fiber lasers also play an important role in a new generation of wind-sensing light-detection-and-ranging (lidar) systems for meteorology, where the Doppler shift of light scattered by aerosols (Mie scattering) is used to indirectly measure wind velocity and turbulence by coherent homodyne detection. This requires first of all a single-frequency, narrow-linewidth source that can deliver up to 1 W of optical power, but also very low relative intensity noise (RIN) to be able to detect the very weak backscatter from aerosols and particles carried by the wind. The laser emits light in the wavelength region at 1.5 μm, which does not cause eye damage to humans or animals.

The use of laser anemometry will be important for future wind-resource management, as the accurate prediction of energy yield is vital to the success of wind-farm projects. Wind data have traditionally been collected using expensive anemometry masts, which can only perform point measurements. This creates great difficulty due to the numerous measurement points throughout the entire wind farm. In addition, raising anemometry masts requires building permits and dealing with health and safety aspects.

Wind lidar systems are now being exploited as forward-looking sensors to predict wind conditions ahead of wind turbines in operation, as opposed to traditional and widely used cup anemometers that are limited to instantaneous measurements at the turbine nacelle, or sonar systems that do predict the wind conditions ahead, but with low accuracy. The ability to reliably predict wind speed and direction will aid in controlling the pitch and yaw of the turbines' blades for increased power optimization and, even more importantly, to reduce load on and fatigue of the large turbine structures. The typical life time of wind turbines is now around 20 years, but it is expected that this could be extended by 30% using wind lidar feedback control to reduce the loads from wind turbulence.1

Other applications that can benefit from wind lidar systems include aviation safety and airport wake-vortex detection at landing fields. NKT Photonics has worked closely with the wind-energy research center Risø DTU National Laboratory for Sustainable Energy (Roskilde, Denmark), gaining know-how of the laser requirements to make its DFB fiber lasers suitable sources for wind lidar systems.

Swarm satellite mission

The Swarm Earth-orbiting satellite mission, conducted by the European Space Agency (ESA), consists of three identical satellites in three different polar Earth orbits between 400 and 550 km altitude; the intent is to provide the best ever survey of the geomagnetic field and its temporal evolution. Launched on November 22, 2013, the satellites deployed their instrument booms and became fully operational on November 26, 2013.

High-precision and high-resolution measurements of the strength and direction of the magnetic field will be provided by each satellite. In combination, they will provide the necessary observations that are required to model various sources of the geomagnetic field. GPS receivers, an accelerometer, and an electric field instrument provide supplementary information for studying the interaction of the magnetic field with other physical quantities describing the Earth system.

The satellites each carry an instrument called the Absolute Scalar Magnetometer (ASM), positioned at the end of the satellites' booms. Developed at CNES (Toulouse, France) and CEA/LETI (Grenoble, France), the ASM provides magnetic field measurements with a 1 pT/Hz0.5 resolution over a 0 to 100 Hz bandwidth.2 The NKT Photonics low-noise fiber lasers inside the ASMs are designed to match the helium transition line at 1083 nm; the laser light pumps helium in the magnetometer, amplifying electronic magnetic resonance effects in the instrument.The National Ignition Facility (NIF) laser-fusion research program at Lawrence Livermore National Laboratory (Livermore, CA) is another scientific program that has exploited high-precision DFB fiber lasers, which are at the heart of the fiber-optic master oscillator circuit providing the stable input for the system's series of amplifiers (see Fig. 2). While not used for sensing in this case, the fiber laser in the master oscillator circuit provides the stable pulses that are then split and tremendously amplified for various experimental uses. The operational lifetime of the NIF is 30 years, and the fiber lasers have proven to provide reliable and stable long-term operation continuously without failures and degradation.3

REFERENCES

1. See http://bit.ly/IDKdm8 (in Danish).

2. J-M. Leger et al., Procedia Chem., 1, 1, 634 (September 2009); http://bit.ly/1gXiIjr.

3. See http://bit.ly/1gXiSY2.

Søren Løvgreen is product manager at NKT Photonics, Birkerød, Denmark; e-mail: [email protected]; www.nktphotonics.com.